MAINTENANCE PROCEDURE

MAINTENANCE

4-54

EVERY 500 HOURS MAINTENANCE

4

Maintenance for every 50 and 250 hours service should be carried out at the same time.

LUBRICATING

4

NOTICE

q

If any abnormal noise is generated from any greasing point, carry out greasing regardless of the

greasing interval.

q

Carry out greasing every 10 hours for the first 50 hours on a new machine.

q

After the machine was subjected to jobs in the water, be sure to grease the wet pins.

q

When carrying out heavy-duty operations, such as hydraulic breaker operations, carry out the greas-

ing every 100 hours.

1.

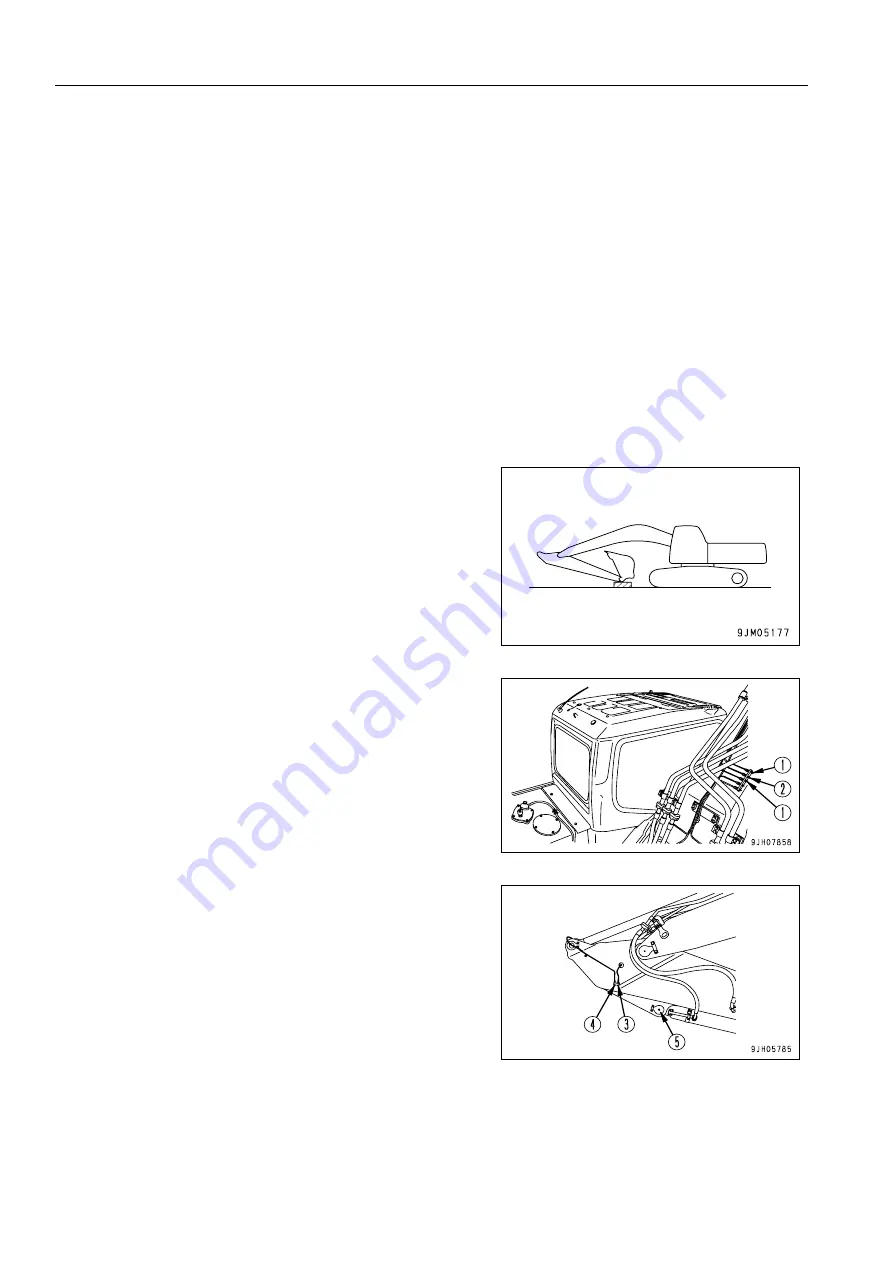

Set the machine to the greasing posture shown on the

right, lower the work equipment to the ground, then stop

the engine.

2.

Using a grease pump, pump in grease through the grease

fittings shown by arrows.

3.

After greasing, wipe off any old grease that was pushed

out.

(1) Boom cylinder rod pin (2 places)

(2) Arm cylinder foot pin (1 places)

(3) Boom-Arm coupling pin (1 place)

(4) Arm cylinder rod end (1 place)

(5) Bucket cylinder foot pin (1 place)

Summary of Contents for PC450-8

Page 2: ......

Page 3: ...FOREWORD 11 ...

Page 66: ...SAFETY MAINTENANCE INFORMATION SAFETY 2 42 ...

Page 351: ...SPECIFICATIONS 15 ...

Page 355: ...SPECIFICATIONS SPECIFICATIONS 5 5 6 7m Boom PC450 8 ...

Page 356: ...SPECIFICATIONS SPECIFICATIONS 5 6 6 7m Boom PC450LC 8 ...

Page 357: ...SPECIFICATIONS SPECIFICATIONS 5 7 6 7m Boom PC450LCHD 8 ...

Page 359: ...SPECIFICATIONS SPECIFICATIONS 5 9 7 0m Boom PC450 8 ...

Page 360: ...SPECIFICATIONS SPECIFICATIONS 5 10 7 0m Boom PC450LC 8 ...

Page 410: ...SUPER LONG FRONT BOOM AND ARM ATTACHMENTS ANDD OPTIONS 6 50 ...

Page 436: ...OPERATION HIGH REACH DEMOLITION EQUIPMENT 27M 7 26 3 Extend arm cylinder Arm cylinder ...

Page 469: ...INDEX 18 ...

Page 470: ...INDEX 8 2 ...

Page 473: ...COLOPHON 18 ...