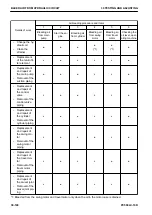

TEST OIL LEAKAGE

Tools for testing oil leakage

Symbol

Part No.

Part name

Q'ty

Remarks

A

Commercially

available

Measuring cylinder

1

B

07379-01044

Flange

2

Size: 10

C

07376-70522

Plug

1

Size: 4

D

Commercially

available

Plate

1

Size: 250x260x32

E

Commercially

available

Pin

1

Size: φ 200x80

k

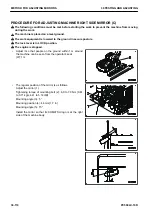

Place the machine on a level ground, and then lower the work equipment completely to the ground in

a stable posture. Set the lock lever to LOCK position, and then stop the engine.

k

Parts and oil are still very hot immediately after the engine is stopped. It may cause burn injury. Wait

for the temperature to go down, and then start the work.

Check this item under the following conditions.

Hydraulic oil temperature: 45 to 55 °C

For testing oil leakage to perform troubleshooting, refer to this section.

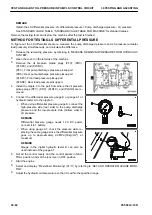

METHOD FOR TESTING OIL LEAKAGE FROM BOOM CYLINDER

1.

Set the boom cylinder at RAISE stroke end, and stop the engine.

2.

Release the remaining pressure from the piping on the boom cylinder head side by referring to “RELEASE

REMAINING PRESSURE FROM HYDRAULIC SYSTEM”.

REMARK

Operate the lever only with the boom RAISE direction to release the remaining pressure.

3.

Disconnect the hose (1) on the cylinder head side and

block the hose side by using plug C.

k

Be careful not to disconnect the hose on the cylin-

der bottom side.

4.

Start the engine.

5.

Select and display “Pre-defined Monitoring” (01/11) by re-

ferring to “SET AND OPERATE MACHINE MONITOR”.

6.

Adjust the hydraulic oil temperature so that it is within the

specified range.

7.

Turn the fuel control dial to MAX (High idle) position.

8.

Operate the work equipment control lever to relieve the

pressure in the boom RAISE circuit.

k

Be careful not to operate the lever to “Boom LOWER” side.

9.

30 seconds after the relief is started, measure the oil leakage for 1 minute.

See STANDARD VALUE TABLE, “STANDARD VALUE TABLE FOR MACHINE” for standard values.

Restore the machine after finishing the test.

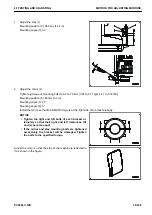

METHOD FOR TESTING OIL LEAKAGE FROM ARM CYLINDER

1.

Set the arm cylinder at IN stroke end, and stop the engine.

2.

Release the remaining pressure from the piping on the arm cylinder head side by referring to “RELEASE

REMAINING PRESSURE FROM HYDRAULIC SYSTEM”.

TEST OIL LEAKAGE

30 TESTING AND ADJUSTING

30-96

PC500LC-10R

Summary of Contents for PC500LC-10R

Page 1: ...HYDRAULIC EXCAVATOR SEN06722 00 PC500LC 10R SERIAL NUMBERS 100001 and up...

Page 2: ......

Page 3: ...00 INDEX AND FOREWORD PC500LC 10R 00 1...

Page 76: ......

Page 77: ...01 SPECIFICATIONS PC500LC 10R 01 1...

Page 94: ......

Page 95: ...10 STRUCTURE AND FUNCTION PC500LC 10R 10 1...

Page 177: ...When balanced 10 STRUCTURE AND FUNCTION CLSS PC500LC 10R 10 83...

Page 178: ...When lever is returned to fine control state CLSS 10 STRUCTURE AND FUNCTION 10 84 PC500LC 10R...

Page 179: ...When lever is pulled at a stroke 10 STRUCTURE AND FUNCTION CLSS PC500LC 10R 10 85...

Page 180: ...When lever is in stroke end CLSS 10 STRUCTURE AND FUNCTION 10 86 PC500LC 10R...

Page 377: ...20 STANDARD VALUE TABLE PC500LC 10R 20 1...

Page 407: ...30 TESTING AND ADJUSTING PC500LC 10R 30 1...

Page 583: ...30 TESTING AND ADJUSTING METHOD FOR STARTING UP KOMTRAX TERMINAL PC500LC 10R 30 177...

Page 604: ......

Page 605: ...60 MAINTENANCE STANDARD PC500LC 10R 60 1...

Page 636: ...MAINTENANCE STANDARD OF MAIN PUMP 60 MAINTENANCE STANDARD 60 32 PC500LC 10R...

Page 638: ...MAINTENANCE STANDARD OF SWING MOTOR 60 MAINTENANCE STANDARD 60 34 PC500LC 10R...

Page 641: ...60 MAINTENANCE STANDARD MAINTENANCE STANDARD OF TRAVEL MOTOR PC500LC 10R 60 37...

Page 644: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 40 PC500LC 10R...

Page 646: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 42 PC500LC 10R...

Page 648: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 44 PC500LC 10R...

Page 650: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 46 PC500LC 10R...

Page 652: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 48 PC500LC 10R...

Page 658: ...MAINTENANCE STANDARD OF TRAVEL PPC VALVE 60 MAINTENANCE STANDARD 60 54 PC500LC 10R...

Page 668: ...MAINTENANCE STANDARD OF WORK EQUIPMENT LINKAGE 60 MAINTENANCE STANDARD 60 64 PC500LC 10R...

Page 679: ...90 CIRCUIT DIAGRAMS PC500LC 10R 90 1...

Page 692: ......

Page 694: ......

Page 696: ......

Page 698: ......

Page 700: ......

Page 704: ...Symbol Content Buzzer Antenna SYMBOLS USED IN ELECTRICAL CIRCUIT DIAGRAM 90 26 PC500LC 10R...

Page 706: ......

Page 708: ......

Page 710: ......

Page 712: ......

Page 714: ......

Page 716: ......

Page 718: ......

Page 720: ......

Page 722: ......

Page 724: ......

Page 726: ......

Page 728: ......

Page 730: ......

Page 732: ......

Page 734: ......

Page 736: ......

Page 738: ......

Page 740: ......

Page 742: ......

Page 744: ......

Page 746: ......

Page 748: ......

Page 757: ......