Unit: mm

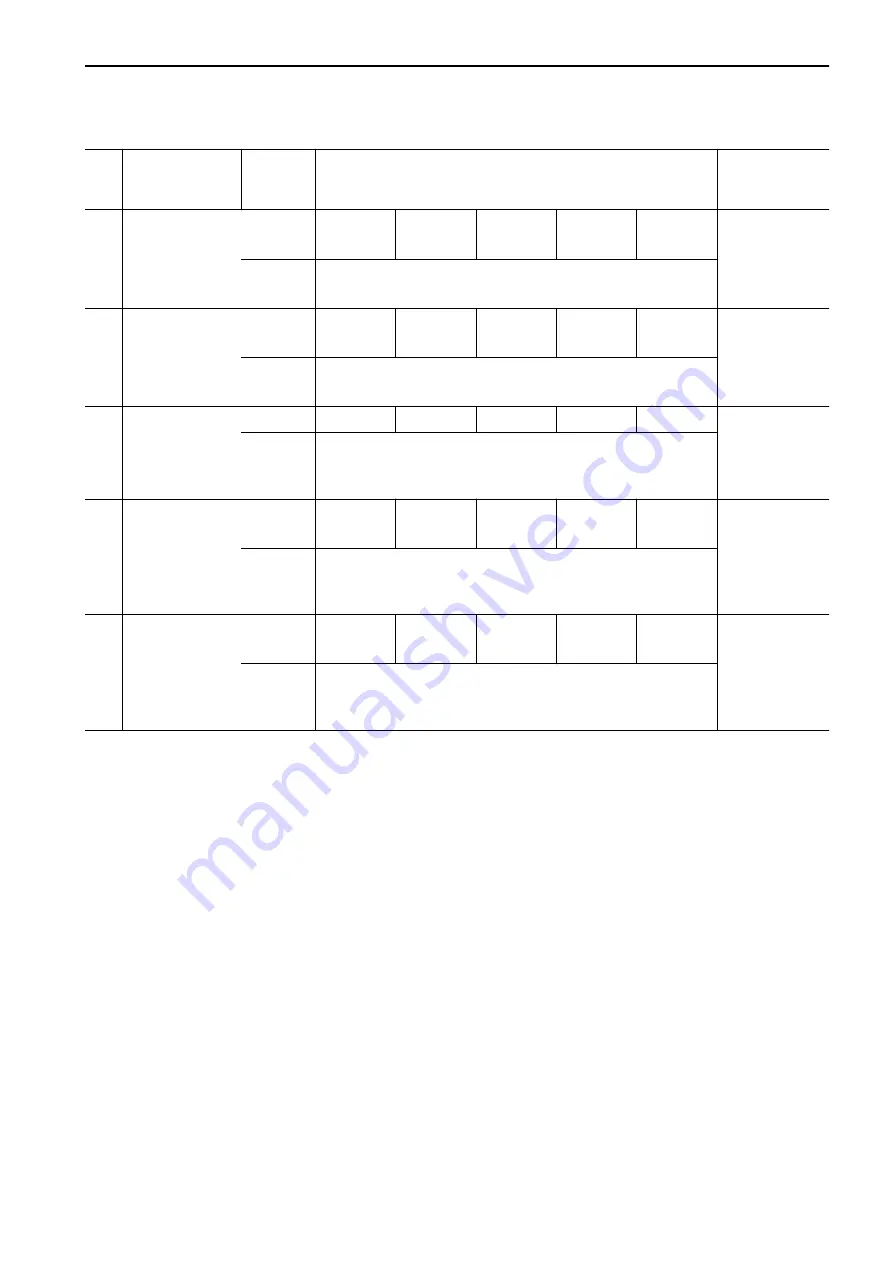

No.

Item

Lubrica-

tion inter-

val

Judgment criteria

Remedy

18

The joint of link

and bucket

411

±0.5

412

+1

0

0.5 to 2.5

-

50 hours

L18: -

R18: -

19a

The joint of buck-

et cylinder and

link

116

±1.2

120

+1.0

-0.5

2.3 to 6.2

-

(*2)

50 hours

L19a: -

R19a: Insert shim whose thickness is 1.5 mm (1).

19b The joint of links

416

±0.5

-

-

-

Clearance is

Max. 1.0 mm.

(*2)

50 hours

L19b: -

R19b: Adjust by combining shims whose thickness is 0.8 mm

(1) and 1.5 mm (3).

20

The joint of arm

and link

416

+0.5

0

-

-

-

Clearance is

Max. 1.0 mm.

(*2)

50 hours

L20: Adjust by combining shims whose thickness is 0.8 mm

(1) and 1.5 mm (3).

R20: -

21

The joint of arm

and bucket

411

+0.2

-0.7

412

+2.6

-0.1

0.7 to 4.3 Adjust the

clearance to be

0.5 to 1.0 mm

by using shims.

(*3)

50 hours

L21: -

R21: Adjust by combining shims whose thickness is 0.5 mm

(4) and 1.0 mm (16).

The quantity in ( ) after each shim thickness indicates the quantity of shim to be prepared.

*1: The criteria are for the R.H. boom cylinder. The shim adjustment position of the L.H. boom cylinder is re-

verse to R.H.

*2: Use steel (non-flanged) shims.

*3: Use split-type steel shims.

60 MAINTENANCE STANDARD

MAINTENANCE STANDARD OF WORK EQUIPMENT LINKAGE

PC500LC-10R

60-67

Summary of Contents for PC500LC-10R

Page 1: ...HYDRAULIC EXCAVATOR SEN06722 00 PC500LC 10R SERIAL NUMBERS 100001 and up...

Page 2: ......

Page 3: ...00 INDEX AND FOREWORD PC500LC 10R 00 1...

Page 76: ......

Page 77: ...01 SPECIFICATIONS PC500LC 10R 01 1...

Page 94: ......

Page 95: ...10 STRUCTURE AND FUNCTION PC500LC 10R 10 1...

Page 177: ...When balanced 10 STRUCTURE AND FUNCTION CLSS PC500LC 10R 10 83...

Page 178: ...When lever is returned to fine control state CLSS 10 STRUCTURE AND FUNCTION 10 84 PC500LC 10R...

Page 179: ...When lever is pulled at a stroke 10 STRUCTURE AND FUNCTION CLSS PC500LC 10R 10 85...

Page 180: ...When lever is in stroke end CLSS 10 STRUCTURE AND FUNCTION 10 86 PC500LC 10R...

Page 377: ...20 STANDARD VALUE TABLE PC500LC 10R 20 1...

Page 407: ...30 TESTING AND ADJUSTING PC500LC 10R 30 1...

Page 583: ...30 TESTING AND ADJUSTING METHOD FOR STARTING UP KOMTRAX TERMINAL PC500LC 10R 30 177...

Page 604: ......

Page 605: ...60 MAINTENANCE STANDARD PC500LC 10R 60 1...

Page 636: ...MAINTENANCE STANDARD OF MAIN PUMP 60 MAINTENANCE STANDARD 60 32 PC500LC 10R...

Page 638: ...MAINTENANCE STANDARD OF SWING MOTOR 60 MAINTENANCE STANDARD 60 34 PC500LC 10R...

Page 641: ...60 MAINTENANCE STANDARD MAINTENANCE STANDARD OF TRAVEL MOTOR PC500LC 10R 60 37...

Page 644: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 40 PC500LC 10R...

Page 646: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 42 PC500LC 10R...

Page 648: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 44 PC500LC 10R...

Page 650: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 46 PC500LC 10R...

Page 652: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 48 PC500LC 10R...

Page 658: ...MAINTENANCE STANDARD OF TRAVEL PPC VALVE 60 MAINTENANCE STANDARD 60 54 PC500LC 10R...

Page 668: ...MAINTENANCE STANDARD OF WORK EQUIPMENT LINKAGE 60 MAINTENANCE STANDARD 60 64 PC500LC 10R...

Page 679: ...90 CIRCUIT DIAGRAMS PC500LC 10R 90 1...

Page 692: ......

Page 694: ......

Page 696: ......

Page 698: ......

Page 700: ......

Page 704: ...Symbol Content Buzzer Antenna SYMBOLS USED IN ELECTRICAL CIRCUIT DIAGRAM 90 26 PC500LC 10R...

Page 706: ......

Page 708: ......

Page 710: ......

Page 712: ......

Page 714: ......

Page 716: ......

Page 718: ......

Page 720: ......

Page 722: ......

Page 724: ......

Page 726: ......

Page 728: ......

Page 730: ......

Page 732: ......

Page 734: ......

Page 736: ......

Page 738: ......

Page 740: ......

Page 742: ......

Page 744: ......

Page 746: ......

Page 748: ......

Page 757: ......