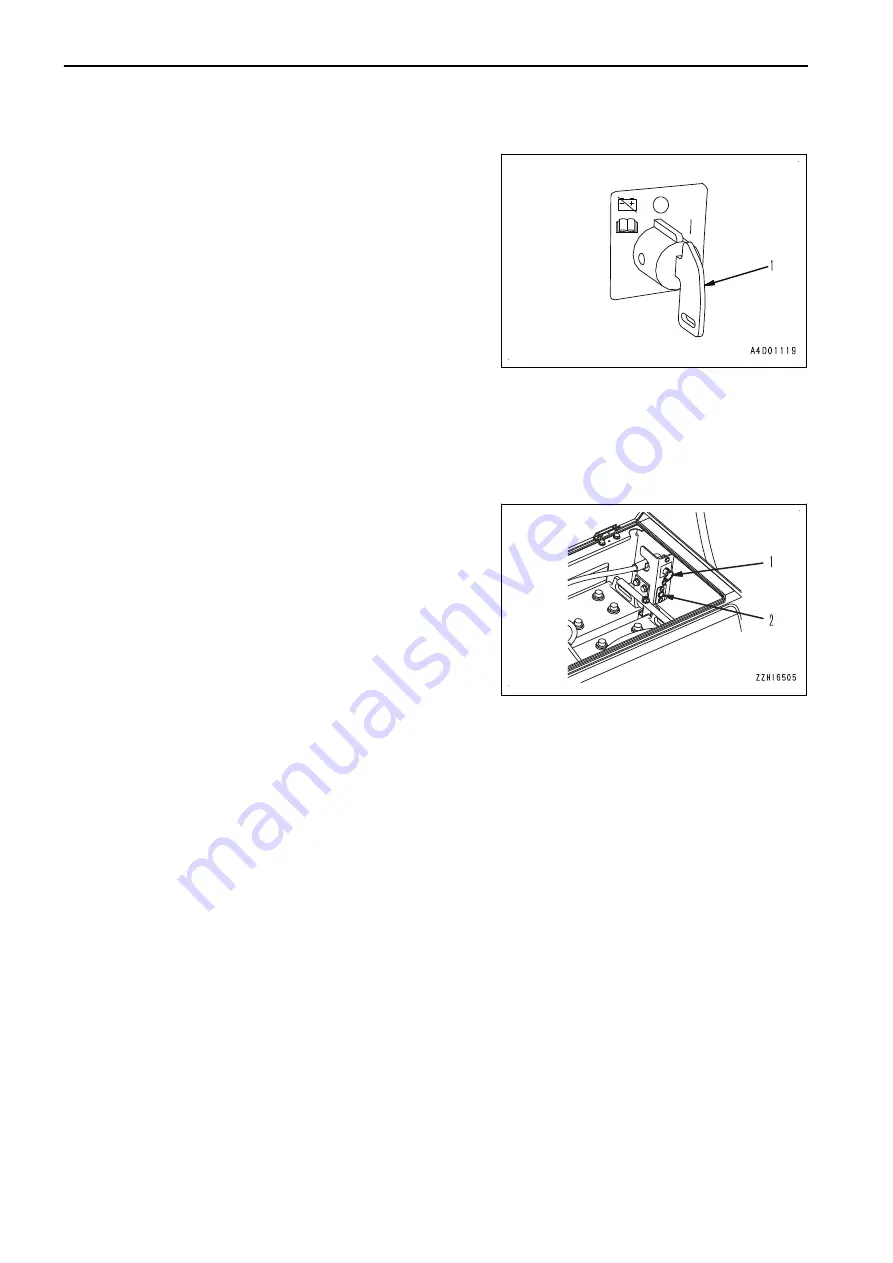

HANDLE BATTERY DISCONNECT SWITCH

(O): OFF position

(I): ON position

• Battery disconnect switch (1) is usually used in the follow-

ing cases in the same purpose of disconnecting the cable

from the negative terminal of the battery.

• When storing the machine for a long period (1 month

or longer)

• When servicing or repairing the electrical system

• When performing the electric welding

• When handling the battery

• When replacing the fuse, etc.

• When the battery disconnect switch (1) is at OFF position, all the continuous power supplies for the compo-

nents including the starting switch B terminal and controllers are all cut out. It is the same state as the time

when the battery is not connected. Accordingly, none of the electrical systems of the machine operates.

k

If the battery disconnect switch (1) is turned to ON position by unauthorized person, it is extremely

dangerous.

NOTICE

When turning the battery disconnect switch (1) to OFF po-

sition, always remove the switch key (1).

• The controllers are protected from abnormal disconnec-

tion, which shuts off the battery power supply circuit even

when the controllers are operating. Check the system op-

erating lamp (2) is lit and see if controllers are in operation.

• Before shutting off the battery power supply circuit, turn the

starting switch to OFF position, and check that the system

operating lamp goes out, then turn the battery disconnect

switch to OFF position.

• If the battery disconnect switch is turned to OFF position (the battery power supply circuit is shut off) while

the system operating lamp is lit, a controller data loss error may occur. Do not operate the battery discon-

nect switch while the system operating lamp is lit.

• The system operating lamp goes out in a maximum of 6 minutes after the starting switch is turned to OFF

position.

• The system operating lamp may sometimes light up while the starting switch is turned to OFF position be-

cause KOMTRAX terminal may maintain its communication under this condition.

• Even if the system operating lamp is not lit it may seem to be lit slightly because of a very little current in-

side the controller. This phenomenon does not indicate abnormality.

• The KOMTRAX terminal performs communication periodically even if the starting switch is kept in OFF

position, thus it repeats starting and stopping.

• The start and stop cycle (sleep cycle) of KOMTRAX terminal varies depending on the factors including

the communication state and the time when the machine is not in operation, and the lamp may be lit

continuously for a maximum of approximately 1 hour.

• If the system operating lamp stays lit when you want to cut off the battery circuit for maintenance, turn the

starting switch to ON position first, then turn it to OFF position. The lamp goes out in the maximum of six

minutes. After the system operating lamp goes out, turn the battery disconnect switch immediately to OFF

position.

HANDLE BATTERY DISCONNECT SWITCH

30 TESTING AND ADJUSTING

30-182

PC500LC-10R

Summary of Contents for PC500LC-10R

Page 1: ...HYDRAULIC EXCAVATOR SEN06722 00 PC500LC 10R SERIAL NUMBERS 100001 and up...

Page 2: ......

Page 3: ...00 INDEX AND FOREWORD PC500LC 10R 00 1...

Page 76: ......

Page 77: ...01 SPECIFICATIONS PC500LC 10R 01 1...

Page 94: ......

Page 95: ...10 STRUCTURE AND FUNCTION PC500LC 10R 10 1...

Page 177: ...When balanced 10 STRUCTURE AND FUNCTION CLSS PC500LC 10R 10 83...

Page 178: ...When lever is returned to fine control state CLSS 10 STRUCTURE AND FUNCTION 10 84 PC500LC 10R...

Page 179: ...When lever is pulled at a stroke 10 STRUCTURE AND FUNCTION CLSS PC500LC 10R 10 85...

Page 180: ...When lever is in stroke end CLSS 10 STRUCTURE AND FUNCTION 10 86 PC500LC 10R...

Page 377: ...20 STANDARD VALUE TABLE PC500LC 10R 20 1...

Page 407: ...30 TESTING AND ADJUSTING PC500LC 10R 30 1...

Page 583: ...30 TESTING AND ADJUSTING METHOD FOR STARTING UP KOMTRAX TERMINAL PC500LC 10R 30 177...

Page 604: ......

Page 605: ...60 MAINTENANCE STANDARD PC500LC 10R 60 1...

Page 636: ...MAINTENANCE STANDARD OF MAIN PUMP 60 MAINTENANCE STANDARD 60 32 PC500LC 10R...

Page 638: ...MAINTENANCE STANDARD OF SWING MOTOR 60 MAINTENANCE STANDARD 60 34 PC500LC 10R...

Page 641: ...60 MAINTENANCE STANDARD MAINTENANCE STANDARD OF TRAVEL MOTOR PC500LC 10R 60 37...

Page 644: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 40 PC500LC 10R...

Page 646: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 42 PC500LC 10R...

Page 648: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 44 PC500LC 10R...

Page 650: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 46 PC500LC 10R...

Page 652: ...MAINTENANCE STANDARD OF CONTROL VALVE 60 MAINTENANCE STANDARD 60 48 PC500LC 10R...

Page 658: ...MAINTENANCE STANDARD OF TRAVEL PPC VALVE 60 MAINTENANCE STANDARD 60 54 PC500LC 10R...

Page 668: ...MAINTENANCE STANDARD OF WORK EQUIPMENT LINKAGE 60 MAINTENANCE STANDARD 60 64 PC500LC 10R...

Page 679: ...90 CIRCUIT DIAGRAMS PC500LC 10R 90 1...

Page 692: ......

Page 694: ......

Page 696: ......

Page 698: ......

Page 700: ......

Page 704: ...Symbol Content Buzzer Antenna SYMBOLS USED IN ELECTRICAL CIRCUIT DIAGRAM 90 26 PC500LC 10R...

Page 706: ......

Page 708: ......

Page 710: ......

Page 712: ......

Page 714: ......

Page 716: ......

Page 718: ......

Page 720: ......

Page 722: ......

Page 724: ......

Page 726: ......

Page 728: ......

Page 730: ......

Page 732: ......

Page 734: ......

Page 736: ......

Page 738: ......

Page 740: ......

Page 742: ......

Page 744: ......

Page 746: ......

Page 748: ......

Page 757: ......