MAINTENANCE SCHEDULE

• If the machine is equipped with a hydraulic breaker, the maintenance schedule for some parts are different.

Check the maintenance interval and perform maintenance. For detail, see “MAINTENANCE INTERVAL

FOR HYDRAULIC BREAKER”.

• When using the engine oil for cold district, the maintenance intervals of the engine oil and filter cartridge are

changed to for every 250 hours.

• If the currently used diesel fuel which does not include the bio-fuel is changed to the one mixed with the

bio-fuel, the replacement interval of the fuel filter is changed as well. See “MAINTENANCE INTERVAL

WHEN DIESEL FUEL MIXED WITH BIO-FUEL IS USED”.

• Contact your Komatsu distributor for changing the maintenance interval of the machine monitor.

MAINTENANCE SCHEDULE TABLE

INITIAL 100 HOURS MAINTENANCE (ONLY AFTER THE FIRST 100 HOURS) .......................................... 4-16

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS) .......................................... 4-16

WHEN REQUIRED ........................................................................................................................................ 4-16

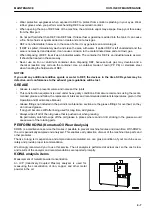

METHOD FOR CHECKING, CLEANING AND REPLACING AIR CLEANER.......................................... 4-16

METHOD FOR CLEANING INSIDE OF COOLING SYSTEM ................................................................. 4-21

METHOD FOR CHECKING LOOSENESS AND TIGHTENING TRACK SHOE BOLTS .......................... 4-23

METHOD FOR CHECKING AND ADJUSTING TRACK TENSION ......................................................... 4-24

METHOD FOR REPLACING BUCKET TEETH (KMAX) ......................................................................... 4-25

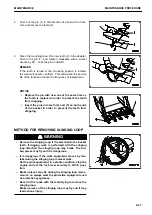

METHOD FOR REMOVING SLINGING LOOP ....................................................................................... 4-27

METHOD FOR REPLACING BUCKET TEETH (HORIZONTAL PIN TYPE)............................................ 4-29

METHOD FOR ADJUSTING BUCKET CLEARANCE ............................................................................. 4-30

METHOD FOR CHECKING WINDOW WASHER FLUID LEVEL, ADDING FLUID ................................. 4-31

METHOD FOR CHECKING AND MAINTENANCE AIR CONDITIONER................................................. 4-31

METHOD FOR REPLACING ADDITIONAL FILTER ELEMENT FOR BREAKER ................................... 4-32

METHOD FOR WASHING WASHABLE FLOOR .................................................................................... 4-33

METHOD FOR BLEEDING AIR FROM HYDRAULIC CIRCUIT .............................................................. 4-37

METHOD FOR CLEANING LINE FILTER AND REMOVING DIRT ......................................................... 4-39

METHOD FOR CLEANING PILOT LINE FILTER AND REMOVING DIRT .............................................. 4-39

CHECKS BEFORE STARTING...................................................................................................................... 4-40

EVERY 10 HOURS MAINTENANCE ............................................................................................................. 4-40

METHOD FOR LUBRICATING ............................................................................................................... 4-40

EVERY 100 HOURS MAINTENANCE ........................................................................................................... 4-42

METHOD FOR LUBRICATING SWING CIRCLE .................................................................................... 4-42

EVERY 250 HOURS MAINTENANCE ........................................................................................................... 4-43

METHOD FOR CHECKING OIL LEVEL IN FINAL DRIVE CASE, ADDING OIL ..................................... 4-43

METHOD FOR CHECKING BATTERY ELECTROLYTE LEVEL ............................................................. 4-44

METHOD FOR CHECKING LOOSENESS AND TIGHTENING TRACK FRAME AND CENTRE FRAME

CONNECTING BOLTS ........................................................................................................................ 4-45

EVERY 500 HOURS MAINTENANCE ........................................................................................................... 4-45

METHOD FOR CHANGING OIL IN ENGINE OIL PAN, REPLACING ENGINE OIL FILTER CARTRIDGE .....

............................................................................................................................................................ 4-46

METHOD FOR REPLACING FUEL PREFILTER CARTRIDGE............................................................... 4-47

METHOD FOR CHECKING SWING PINION GREASE LEVEL, ADD GREASE ..................................... 4-49

METHOD FOR CHECKING AND CLEANING RADIATOR FINS, OIL COOLER FINS, AFTERCOOLER

FINS, FUEL COOLER FINS, AND AIR CONDITIONER CONDENSER FINS...................................... 4-50

METHOD FOR CLEANING AIR CONDITIONER FRESH/RECIRC FILTERS.......................................... 4-51

METHOD FOR CLEANING PTO LUBRICATION FILTER STRAINER .................................................... 4-53

EVERY 1000 HOURS MAINTENANCE ......................................................................................................... 4-53

METHOD FOR REPLACING HYDRAULIC OIL FILTER ELEMENT........................................................ 4-54

METHOD FOR CHANGE OIL IN SWING MACHINERY CASE ............................................................... 4-55

METHOD FOR CHANGING OIL IN PTO CASE...................................................................................... 4-56

METHOD FOR REPLACING FUEL MAIN FILTER CARTRIDGE ............................................................ 4-57

METHOD FOR CHECKING ALL TIGHTENING POINTS OF ENGINE INTAKE PIPE CLAMPS.............. 4-58

METHOD FOR CHECKING WELDED STRUCTURE ............................................................................. 4-58

MAINTENANCE SCHEDULE

MAINTENANCE

4-12

Summary of Contents for PC700LC-11

Page 2: ......

Page 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Page 66: ......

Page 316: ......

Page 396: ......

Page 397: ...SPECIFICATIONS 5 1...

Page 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Page 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Page 426: ......

Page 427: ...REPLACEMENT PARTS 7 1...

Page 434: ......