• Cutting position (B)-(B)

For the upper part of tooth (2)

Cut off at the position 10 to 20 mm away from the

body.

5.

Finish the cutting face smoothly with a grinder.

6.

Check that the section is not cracked.

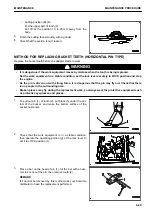

METHOD FOR REPLACING BUCKET TEETH (HORIZONTAL PIN TYPE)

Replace the bucket teeth before the adapter starts to wear.

k

k

WARNING

• It is dangerous if the work equipment moves by mistake when the tooth is being replaced.

Set the work equipment in a stable condition, set the lock lever securely to LOCK position and stop

the engine.

• As the pin is driven out with strong force, it is dangerous that the pin may fly out. Check that there

is no people in the surrounding area.

• Broken pieces may fly during the replacement work, so always wear the protective equipment such

as protective eyeglasses and gloves.

1.

To pull out pin (1) of tooth (2), put block (5) under the bot-

tom of the bucket, and make the bottom surface of the

bucket horizontal.

2.

Check that the work equipment is in a stable condition,

then operate the operating portion (g) of the lock lever to

set it to LOCK position (L).

3.

Place a bar on the head of pin (1), hit the bar with a ham-

mer to knock out the pin, then remove tooth (2).

REMARK

If it cannot be removed by this method, ask your Komatsu

distributor to have the replacement performed.

MAINTENANCE

MAINTENANCE PROCEDURE

4-29

Summary of Contents for PC700LC-11

Page 2: ......

Page 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Page 66: ......

Page 316: ......

Page 396: ......

Page 397: ...SPECIFICATIONS 5 1...

Page 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Page 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Page 426: ......

Page 427: ...REPLACEMENT PARTS 7 1...

Page 434: ......