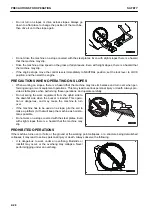

• Always wear protective eyeglasses and rubber gloves

when starting the engine by using the jumper cables.

• When connecting a normal machine to a failed machine

with the jumper cables, always use the normal machine

with the same battery voltage as the failed machine.

• When starting the engine with the jumper cables, perform

the starting operation with 2 workers (one worker sitting in

the operator's seat and the other working with the battery).

• When starting from another machine, be careful that the

normal machine does not contact with the failed machine.

• When connecting the jumper cables, turn the starting

switch to OFF position for both the failed machine and the normal machine. If the failed machine has a bat-

tery disconnect switch, turn it to OFF position, and turn it ON again after connecting the cables.

It is dangerous that the machine may move when the power is connected.

• Be sure to connect the positive (+) cable first when installing the jumper cables. Disconnect the negative (-)

cable (ground side) first when removing them.

• When disconnecting the jumper cables, take care not to bring the clips in contact with each other or with the

machine.

PRECAUTIONS FOR OPERATION

CHECKS BEFORE OPERATION

If the checks before starting are not performed properly, the machine will be unable to display its full perform-

ance. It is dangerous and may cause serious personal injury or death.

When performing the checks, move the machine to a wide area with no obstructions, and pay careful attention

to the surroundings. Prohibit other personnel from coming close to the machine during checks.

• Fasten the seatbelt. When the brakes are applied sudden-

ly, the operator may be thrown out of the operator's seat. It

is dangerous and may cause personal injury.

• Check that the movement of the machine matches the dis-

play on the control pattern card.

If it does not match, replace it immediately with the correct

control pattern card.

• Check the operating condition of the machine, work equip-

ment, and travel and swing systems.

• Check for any problem in the sound, vibration, heat and

smell of the machine, or abnormalities of instruments. Also

check that there is no leakage of oil or fuel.

• If any problem is found, repair it immediately.

PRECAUTIONS WHEN TRAVELING IN FORWARD OR REVERSE AND SWINGING

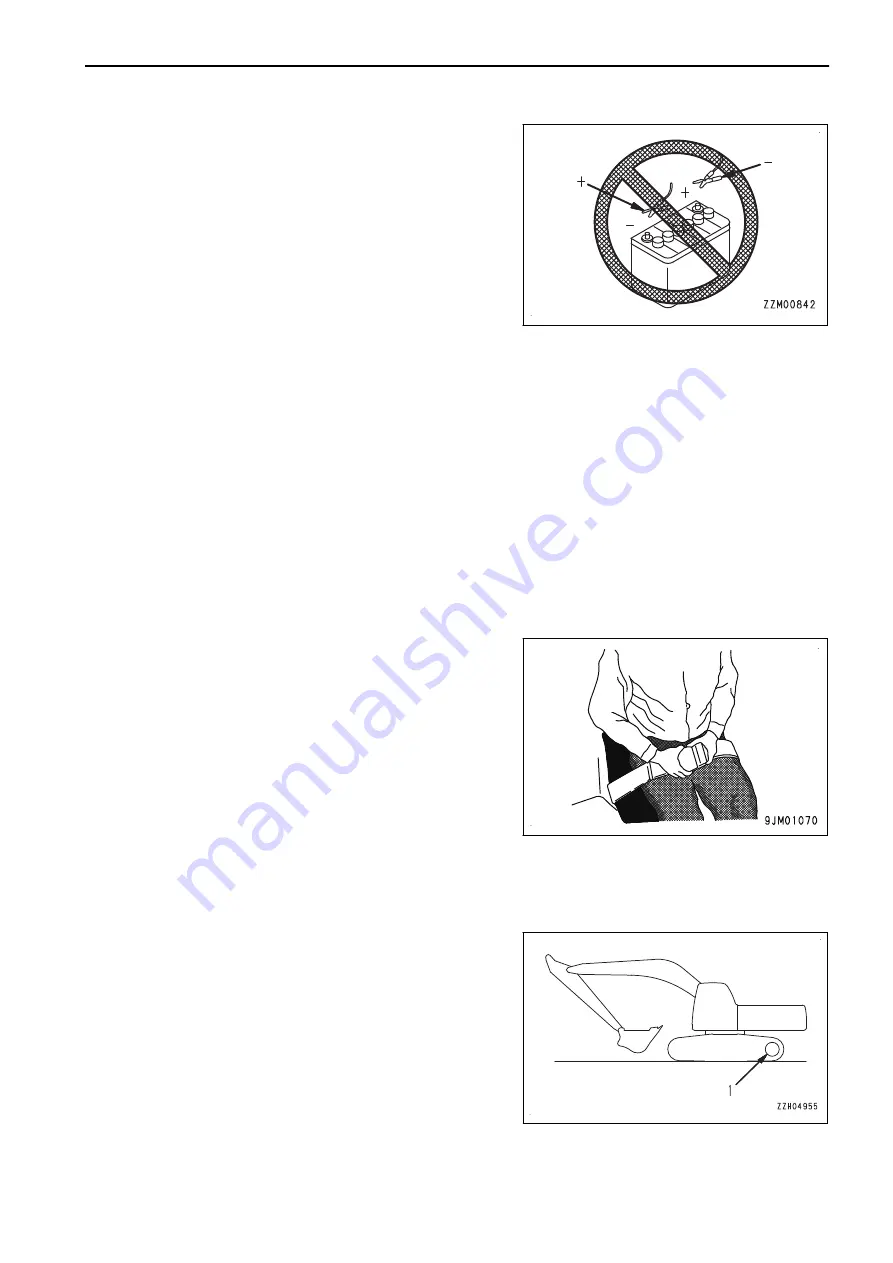

• When driving the machine, drive with sprocket (1) at the

rear of the machine. If sprocket (1) is at the front, the oper-

ation of the travel levers will be the opposite of the actual

direction of travel, so there is a hazard that the machine

may travel in an unexpected direction, leading to serious

injury or death.

• Always lock all the doors and windows of the operator's

compartment in position regardless of whether it is open or

closed.

Always close all the windows and doors on jobsites where

there is danger of scattering fragments, and things which

may intrude into operator's cab.

• Prohibit anyone other than the operator to get on the machine.

SAFETY

PRECAUTIONS FOR OPERATION

2-25

Summary of Contents for PC700LC-11

Page 2: ......

Page 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Page 66: ......

Page 316: ......

Page 396: ......

Page 397: ...SPECIFICATIONS 5 1...

Page 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Page 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Page 426: ......

Page 427: ...REPLACEMENT PARTS 7 1...

Page 434: ......