REMARK

• It is recommended to use a nozzle having a diameter and a length specified by ISO 22241-4 and an auto

stop function to add DEF. When the specified nozzle is used, the magnet installed inside the filler port of the

tank cancels the wrong fluid addition prevention device, and you can add DEF. This mechanism prevents

addition of DEF into the fuel tank, addition of fuel into DEF tank, and spill of DEF from the filler port.

• When using a nozzle which is not conformed to ISO 22241-4, hold it in your hand and add DEF carefully

while checking the sight gauge.

• Add only DEF in clearly marked DEF tanks that have the blue cap.

METHOD FOR CHECKING WORKING LAMP

Check that the working lamps and lamps inside the instruments light up properly. Check also that there is no dirt

or damage.

1.

Turn the starting switch to ON position.

2.

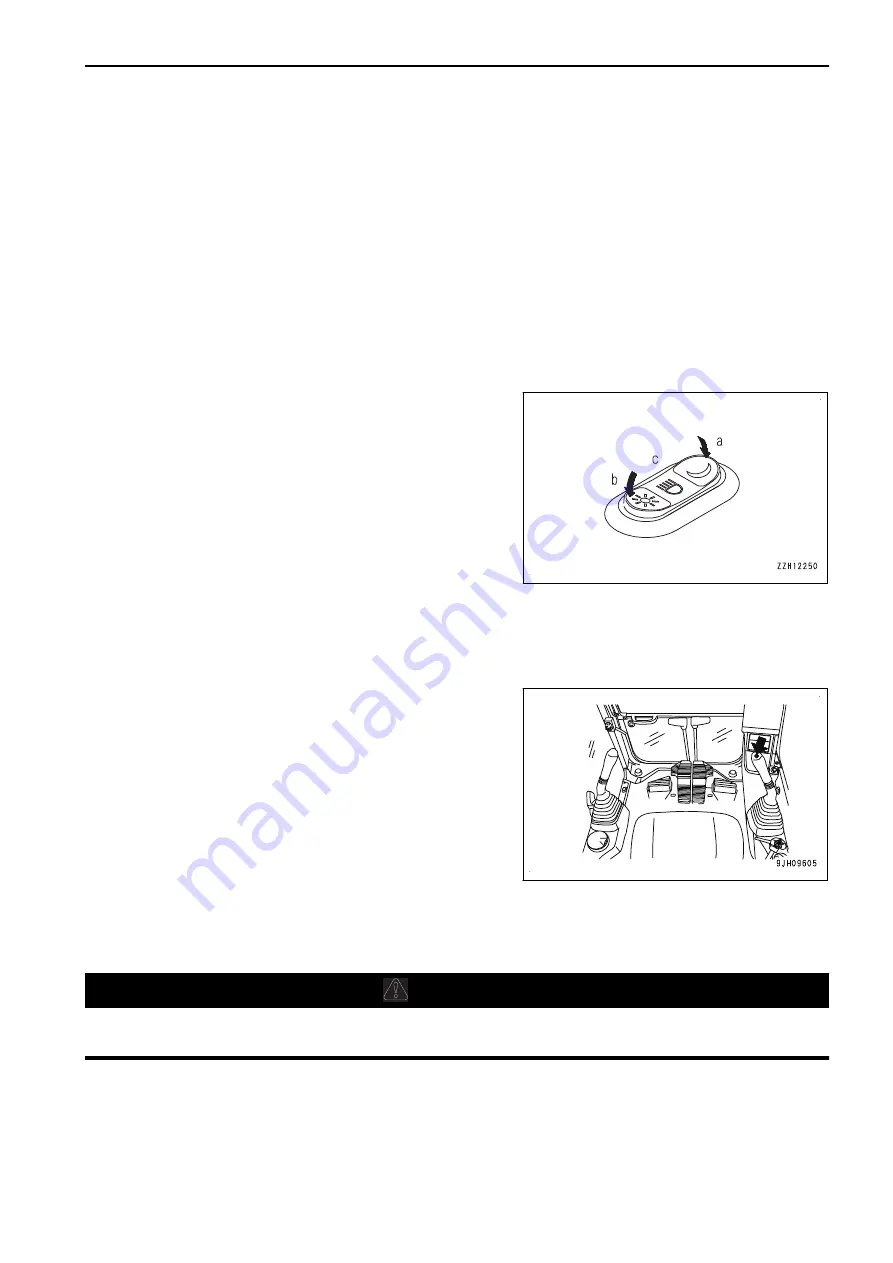

Check that the working lamp lights up properly when the

lamp switch is at night mode (a) and at day mode (b).

3.

After inspection, turn the lamp switch to OFF position (c),

and the working lamp goes out.

4.

After checking, turn the starting switch back to OFF posi-

tion.

If the lamps do not light up, a broken bulb or disconnected wire are the possible causes. Ask your Komatsu

distributor for repairs.

METHOD FOR CHECKING HORN

1.

Turn the starting switch to ON position.

2.

Check that the horn sounds immediately when the horn

switch is pressed.

3.

After checking, return the starting switch to OFF position.

If the horn does not sound, ask your Komatsu distributor for repair.

METHOD FOR ADJUSTING

METHOD FOR ADJUSTING OPERATOR'S SEAT

k

k

WARNING

When adjusting the position of the operator's seat, always set the lock lever to LOCK position to pre-

vent any malfunction due to accidental contact with the control levers.

NOTICE

If the seat position is adjusted while the parts, tools, or empty cans are left around the operator's seat,

the peripheral parts or operator's seat may be damaged.

Check that there is no parts etc., around the operator's seat, and adjust the seat position.

OPERATION

MACHINE OPERATIONS AND CONTROLS

3-149

Summary of Contents for PC700LC-11

Page 2: ......

Page 23: ...LOCATION OF SAFETY LABELS 5 SAFETY SAFETY LABELS 2 3...

Page 66: ......

Page 316: ......

Page 396: ......

Page 397: ...SPECIFICATIONS 5 1...

Page 401: ...For 7 6m Boom SPECIFICATIONS SPECIFICATIONS 5 5...

Page 402: ...SPECIFICATIONS SPECIFICATIONS 5 6...

Page 426: ......

Page 427: ...REPLACEMENT PARTS 7 1...

Page 434: ......