FOREWORD

STANDARD TIGHTENING TORQUE

00-12

STANDARD TIGHTENING TORQUE

STANDARD TIGHTENING TORQUE TABLE (WHEN USING TORQUE WRENCH)

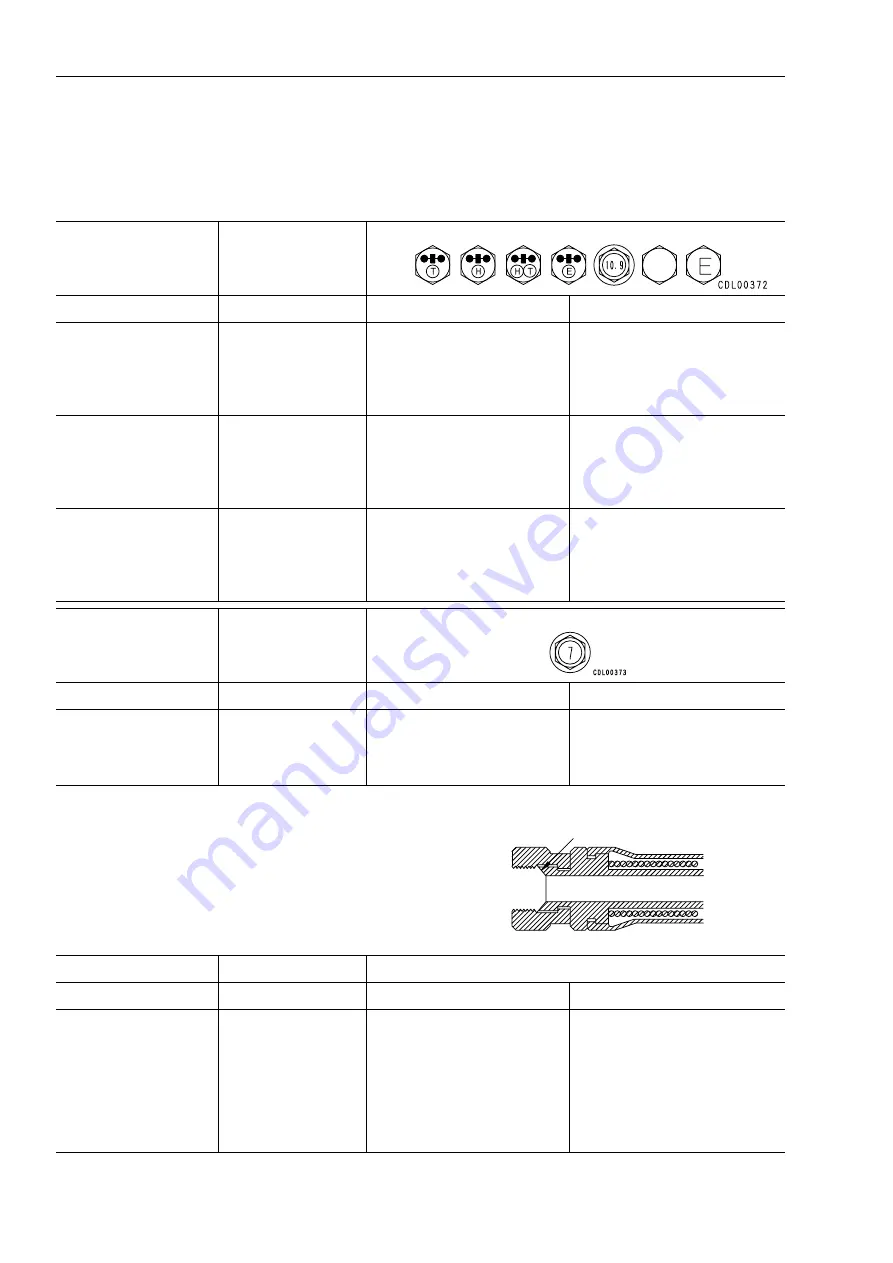

★

In the case of metric nuts and bolts for which there is no special instruction, tighten to the torque given in

the table below.

TABLE OF TIGHTENING TORQUES FOR FLARED NUTS

★

In the case of flared nuts for which there is no

special instruction, tighten to the torque given in

the table below.

Thread diameter

of bolt

Width across

flats

Tightening torque

mm

mm

Nm

kgm

6

8

10

12

14

10

13

17

19

22

11.8 – 14.7

27 – 34

59 – 74

98 – 123

153 – 190

1.2 – 1.5

2.8 – 3.5

6 – 7.5

10 – 12.5

15.5 – 19.5

16

18

20

22

24

24

27

30

32

36

235 – 285

320 – 400

455 – 565

610 – 765

785 – 980

23.5 – 29.5

33 – 41

46.5 – 58

62.5 – 78

80 – 100

27

30

33

36

39

41

46

50

55

60

1150 – 1440

1520 – 1910

1960 – 2450

2450 – 3040

2890 – 3630

118 – 147

155 – 195

200 – 250

250 – 310

295 – 370

Thread diameter

of bolt

Width across

flats

Tightening torque

mm

mm

Nm

kgm

6

8

10

12

10

13

14

27

5.9 – 9.8

13.7 – 23.5

34.3 – 46.1

74.5 – 90.2

0.6 – 1.0

1.4 – 2.4

3.5 – 4.7

7.6 – 9.2

SAD00483

Sealing surface

Thread diameter

Width across flat

Tightening torque

mm

mm

Nm

kgm

14

18

22

24

30

33

36

42

19

24

27

32

36

41

46

55

24.5 ± 4.9

49 ± 19.6

78.5 ± 19.6

137.3 ± 29.4

176.5 ± 29.4

196.1 ± 49

245.2 ± 49

294.2 ± 49

2.5 ± 0.5

5 ± 2

8 ± 2

14 ± 3

18 ± 3

20 ± 5

25 ± 5

30 ± 5