OUTLINE OF MAINTENANCE

• Komatsu recommends using Komatsu genuine parts for replacement parts, grease or oil.

• When changing the oil or adding oil, do not mix different types of oil. When changing the type of oil, drain all

the old oil and fill completely with the new oil. Always replace the filter at the same time. (There is no prob-

lem if the small amount of oil remaining in the piping mixes with the new oil.)

• Unless otherwise specified, when the machine is shipped from the plant, it is filled with the oil and coolant

listed in the table below.

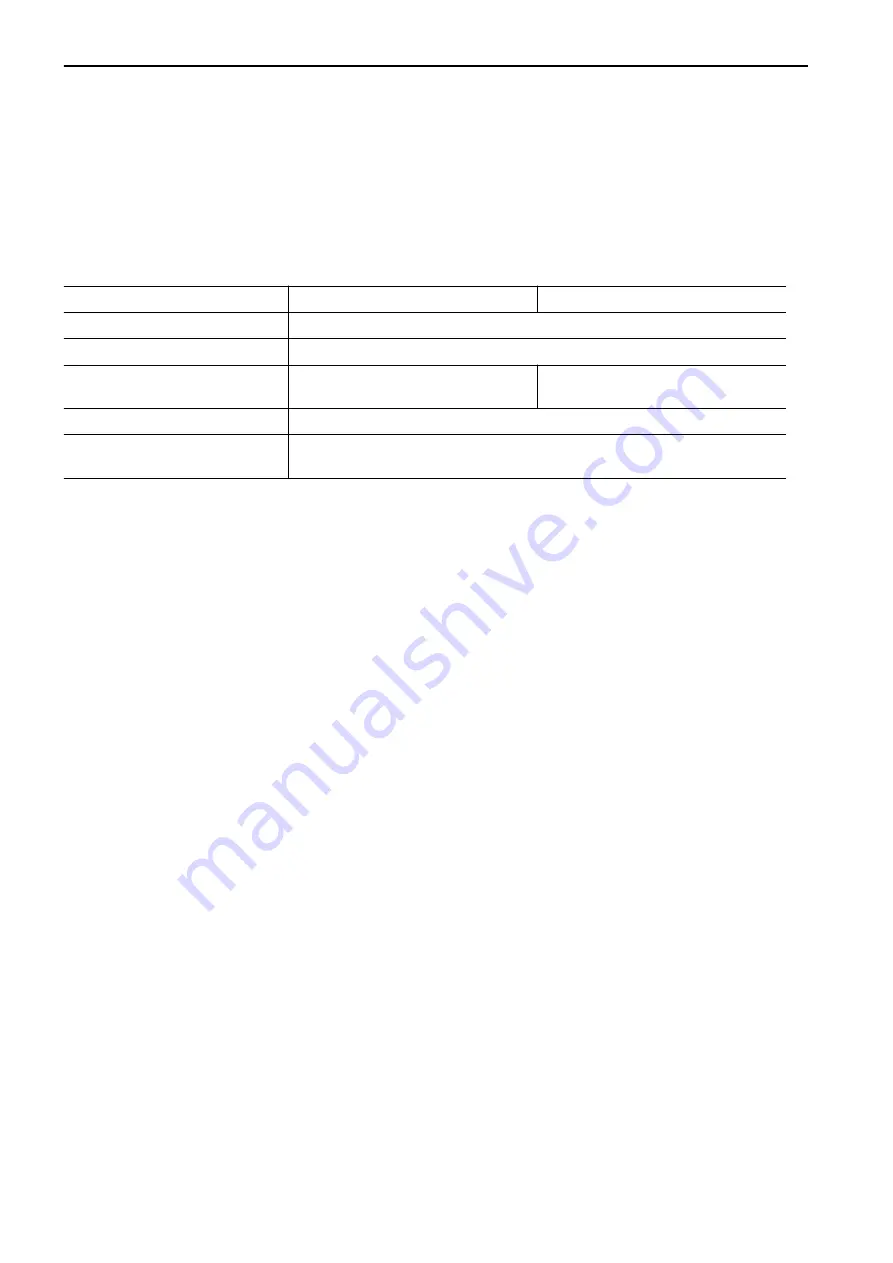

Item

First filling type

Maintenance type

Engine oil pan

Engine oil EO15W40–LA CK4 (Komatsu genuine)

Swing machinery case

Power train oil TO30 (Komatsu genuine)

Final drive case

JX Nippon Oil GL-4 90

Power train oil TO30 (Komatsu genu-

ine)

Hydraulic oil system

Power train oil TO10 (Komatsu genuine)

Radiator

Non-Amine Engine Coolant (AF-NAC) (Komatsu genuine) (density: 30% or

above)

HANDLE OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

OIL

• Oil is used in the engine and hydraulic equipment under extremely severe conditions (high temperature,

high pressure), and deteriorates with use.

Always use oil that matches the grade and maximum and minimum ambient temperatures recommended in

Operation and Maintenance Manual.

Even if the oil is not dirty, always change the oil at the specified interval.

• Oil corresponds to blood in the human body, always be careful when handling it to prevent any impurities

(water, metal particles, dirt, etc.) from getting in.

The majority of failures with the machine are caused by the entry of such impurities.

Take particular care not to let any impurities get in when storing or adding oil.

• Never mix oils of different grades or brands.

• Always add the specified amount of oil.

Having too much oil or too little oil are both causes of failures.

• If the oil in the work equipment is not clear, there is probably water or air getting into the circuit. In such

cases, consult your Komatsu distributor.

• When changing the oil, always replace the related filters at the same time.

• We recommend that you have an oil analysis periodically to check the condition of the machine. For those

who wish to use this service, consult your Komatsu distributor.

• When using commercially available oil, it may be necessary to reduce the oil change interval. We recom-

mend that you use the Komatsu oil clinic to check the characteristics of the oil in detail.

NOTICE

Komatsu recommends using Komatsu genuine engine oil for KDPF. If engine oil other than Komatsu

genuine oil for KDPF is used, it may shorten cleaning interval of KDPF filters, adversely affect the en-

gine such as deteriorated oil may reduce lubricating function, and it may cause failure, shortening of

the machine life, lowering of performance and increase of fuel consumption.

FUEL

• To prevent the moisture in the air from condensing and forming water inside the fuel tank, always fill the fuel

tank with fuel after completing the day's work.

• The fuel pump is a precision equipment, and if fuel containing water or dirt is used, it cannot work properly.

• Be extremely careful not to let impurities get in when storing or adding fuel.

OUTLINE OF MAINTENANCE

MAINTENANCE

4-4

WENAM00241

Summary of Contents for PC80MR-5E0

Page 2: ......

Page 12: ...Do not repeatedly handle and lift loads VIBRATION LEVELS FOREWORD 1 10 WENAM00241...

Page 70: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA67920 GENERAL VIEW OPERATION 3 2 WENAM00241...

Page 76: ...11 Fusible link 12 Ashtray if equipped 13 Tool boxes GENERAL VIEW OPERATION 3 8 WENAM00241...

Page 343: ...SPECIFICATIONS 5 1 WENAM00241...

Page 394: ...WENAM00241...

Page 395: ...REPLACEMENT PARTS 7 1 WENAM00241...

Page 411: ......

Page 412: ......