3.

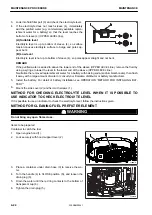

Look into fluid filler port (3) and check the electrolyte level.

4.

If the electrolyte does not reach sleeve (4), immediately

add the purified water (e.g. commercially available replen-

ishment water for a battery) so that the level reaches the

bottom of sleeve (4) (UPPER LEVEL line).

(A) Suitable level

Electrolyte level is up to bottom of sleeve (4), so surface

tension causes electrolyte surface to bulge and poles ap-

pear bent.

(B) Low level

Electrolyte level is not up to bottom of sleeve (4), so poles appear straight and not bent.

REMARK

If the purified water is added to above the lower end of the sleeve (UPPER LEVEL line), remove the fluid by

using a syringe to lower the level to the lower end of the sleeve (UPPER LEVEL line).

Neutralize the removed replenishment water for a battery with baking soda (sodium bicarbonate), then flush

it away with a large amount of water or consult your Komatsu distributor or battery manufacturer.

5.

Install the battery. For detail of battery installation see OPERATION “METHOD FOR INSTALLING BAT-

TERY”

6.

Mount the side cover (2) and fix it with screws (1).

METHOD FOR CHECKING ELECTROLYTE LEVEL WHEN IT IS POSSIBLE TO

USE INDICATOR TO CHECK ELECTROLYTE LEVEL

If it is possible to use an indicator to check the electrolyte level, follow the instructions given.

METHOD FOR CLEANING FUEL PREFILTER ELEMENT

k

k

WARNING

Do not bring any open flame close.

Items to be prepared

Container to catch the fuel

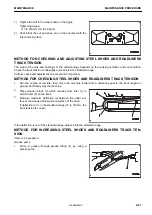

1.

Open engine hood (1).

2.

Lock securely with hood support lever (2).

3.

Place a container under drain hose (3) to receive the wa-

ter.

4.

Turn the handle (4) to CLOSE position (S), and loosen the

drain plug (5).

5.

Drain the water until the red ring contacts to the bottom of

transparent cup (6).

6.

Tighten the drain plug (5).

RKA68180

RKA68193

MAINTENANCE PROCEDURE

MAINTENANCE

4-24

WENAM00241

Summary of Contents for PC80MR-5E0

Page 2: ......

Page 12: ...Do not repeatedly handle and lift loads VIBRATION LEVELS FOREWORD 1 10 WENAM00241...

Page 70: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA67920 GENERAL VIEW OPERATION 3 2 WENAM00241...

Page 76: ...11 Fusible link 12 Ashtray if equipped 13 Tool boxes GENERAL VIEW OPERATION 3 8 WENAM00241...

Page 343: ...SPECIFICATIONS 5 1 WENAM00241...

Page 394: ...WENAM00241...

Page 395: ...REPLACEMENT PARTS 7 1 WENAM00241...

Page 411: ......

Page 412: ......