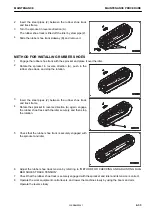

3.

Run the engine at low idle and swing the upper structure

90 ° to bring the work equipment to the side of the track.

4.

Push up the machine until the track is raised slightly from

the ground. Perform idle rotation of track for 2 minutes.

Repeat this procedure on both the right and left sides.

Bleeding air from attachment (when installed)

Perform it when any hydraulic component or oil is replaced.

NOTICE

If the air bleeding procedure is specified on the attachment by the manufacturer, bleed the air according

to that procedure.

If a breaker or other attachment is installed, perform the air bleeding procedure until the air is completely bled

from the attachment circuit.

1.

Run the engine at low idle.

2.

Operate the attachment control switch repeatedly (approximately 10 times).

Air is bled.

NOTICE

• After completing the air bleeding operation, stop the engine, leave the machine for 5 minutes, and

then start the operation. This discharges the air bubbles in the oil inside the hydraulic tank.

• Check for oil leakage and wipe off any spilled oil.

CHECKS BEFORE STARTING

For the following items, see OPERATION, “METHOD FOR CHECKING BEFORE STARTING”.

• Drain water and sediment from fuel tank

• Check water separator, drain water and sediment

• Check oil level in hydraulic tank, add oil

• Check coolant level, add coolant

• Check oil level in engine oil pan, add oil

• Check electric wiring

• Check fuel level, add fuel

• Check horn

EVERY 100 HOURS MAINTENANCE

METHOD FOR LUBRICATING WORK EQUIPMENT

NOTICE

If any unusual noise is generated from any greasing point, perform greasing regardless of the greasing

interval.

Perform greasing every 10 hours for the first 50 hours operation on a new machine.

After the machine is subjected to digging work in the water, be sure to grease the wet pins.

Prepare a grease pump.

MAINTENANCE

MAINTENANCE PROCEDURE

4-43

WENAM00241

Summary of Contents for PC80MR-5E0

Page 2: ......

Page 12: ...Do not repeatedly handle and lift loads VIBRATION LEVELS FOREWORD 1 10 WENAM00241...

Page 70: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA67920 GENERAL VIEW OPERATION 3 2 WENAM00241...

Page 76: ...11 Fusible link 12 Ashtray if equipped 13 Tool boxes GENERAL VIEW OPERATION 3 8 WENAM00241...

Page 343: ...SPECIFICATIONS 5 1 WENAM00241...

Page 394: ...WENAM00241...

Page 395: ...REPLACEMENT PARTS 7 1 WENAM00241...

Page 411: ......

Page 412: ......