1.

Run the engine at low idle.

2.

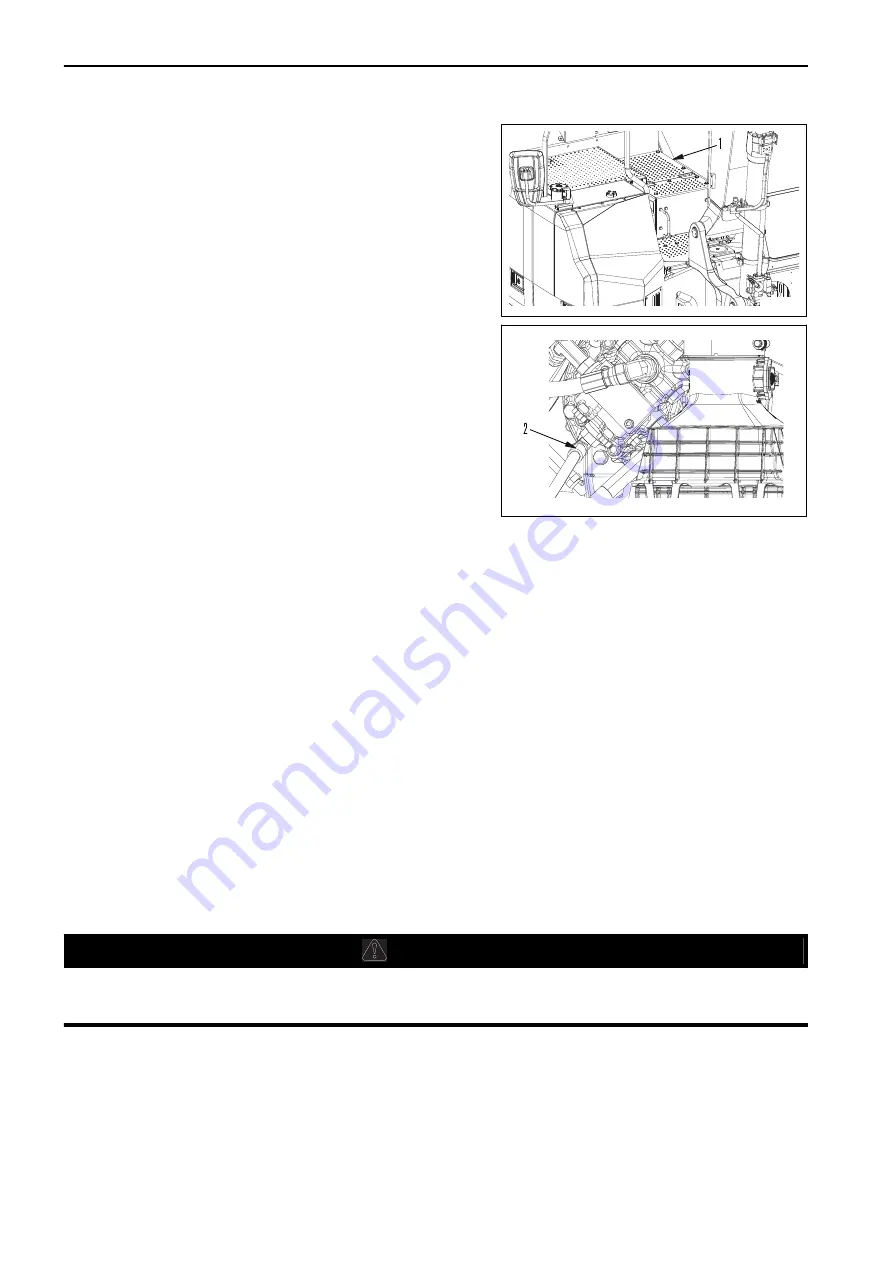

Remove the cover (1).

3.

Loosen the hose on port S, and check that oil exits from

the fitting.

NOTICE

At this time, do not swing the upper structure.

4.

If oil does not exit, stop the engine, remove the hose (2),

and fill the motor with hydraulic oil.

Plug the hose to avoid impurities entering.

5.

After air bleeding, connect the hose (2) to the fitting.

6.

Run the engine at low idle and slowly swing at least 2

turns uniformly to the right and left.

METHOD FOR BLEEDING AIR FROM ATTACHMENT (WHEN ATTACHMENT IS

EQUIPPED)

Perform it when any hydraulic component or oil has been replaced.

NOTICE

If the air bleeding procedure is specified on the attachment by the manufacturer, bleed the air according

to that procedure.

If a breaker or other attachment is installed, perform the air bleeding procedure until the air is completely bled

from the attachment circuit.

1.

Run the engine at low idle.

2.

Operate the attachment control switch repeatedly (approximately 10 times).

Air is bled.

NOTICE

• After completing the air bleeding operation, stop the engine, leave the machine for 5 minutes, and

then start the operation. This discharges the air bubbles in the oil inside the hydraulic tank.

• Check for oil leakage and wipe off any spilled oil.

METHOD FOR CHECKING WHEEL NUT TIGHTENING

k

k

WARNING

• Do not increase the specified tightening torque and keep it within the prescribed ranges.

• Avoid lubricating the thread when the tightening torque must be checked.

This check serves to restore the correct tightening torque of the wheels on the hubs.

The tightening torque must be checked by means of a torque wrench (1).

Tightening: 550±5 Nm

RKA65031

RKA65220

MAINTENANCE PROCEDURE

MAINTENANCE

4-32

WENAM00130

Summary of Contents for PW118MR-11

Page 2: ......

Page 9: ...Do not repeatedly handle and lift loads FOREWORD VIBRATION LEVEL 1 7 WENAM00130...

Page 22: ...WENAM00130...

Page 25: ...LOCATION OF SAFETY LABELS RKA64590 SAFETY SAFETY LABELS 2 3 WENAM00130...

Page 72: ...WENAM00130...

Page 74: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA61930 GENERAL VIEW OPERATION 3 2 WENAM00130...

Page 77: ...CONTROLS AND GAUGES NAMES RKA62690 OPERATION GENERAL VIEW 3 5 WENAM00130...

Page 168: ...SWITCHES RKA63060 EXPLANATION OF COMPONENTS OPERATION 3 96 WENAM00130...

Page 328: ...WENAM00130...

Page 412: ...WENAM00130...

Page 413: ...SPECIFICATIONS 5 1 WENAM00130...

Page 445: ...REPLACEMENT PARTS 7 1 WENAM00130...

Page 461: ......

Page 462: ......