REMARK

If the purified water is added to above UPPER LEVEL (U.L.) line, remove the fluid by using a syringe to lower

the level to UPPER LEVEL (U.L.) line. Neutralize the removed electrolyte with baking soda (sodium bicarbon-

ate), then flush it away with a large amount of water. If necessary, consult your Komatsu distributor or a battery

manufacturer.

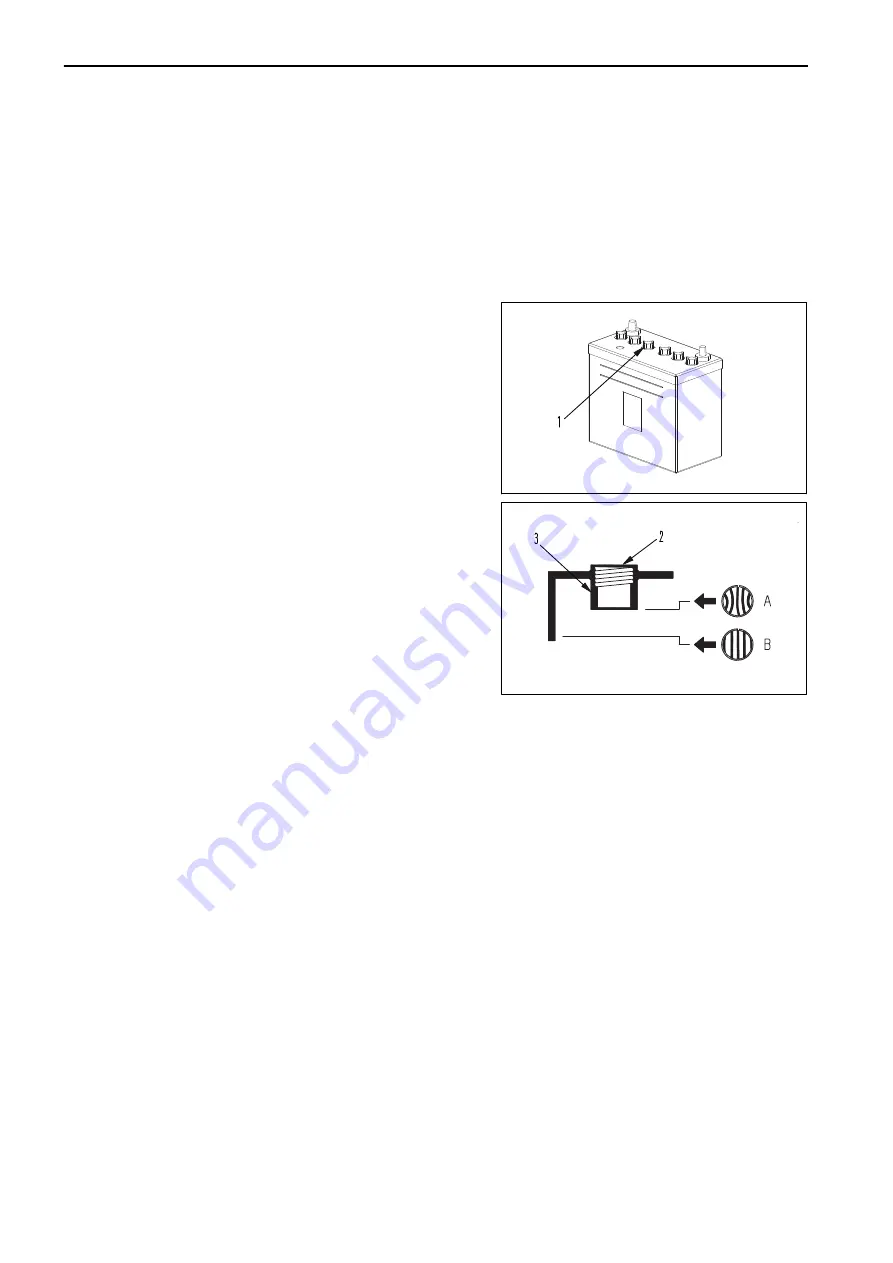

If it is impossible to check electrolyte level from side of battery

If it is impossible to check the electrolyte level from the side of the battery, or there is no UPPER LEVEL line on

the side of the battery, check according to the following procedures.

1.

Remove the cap (1) from the top of the battery.

2.

Look into fluid filler port (2) and check the electrolyte level.

3.

If the electrolyte does not reach the sleeve (3), always add

the purified water (e.g. commercially available replenish-

ment water for a battery) so that the level reaches the bot-

tom of the sleeve (UPPER LEVEL line).

(A) Suitable level

Electrolyte level is up to bottom of sleeve, so surface ten-

sion causes electrolyte surface to bulge and poles appear

bent.

(B) Low level:

Electrolyte level is not up to bottom of sleeve, so poles appear straight and not bent.

4.

After adding the purified water, tighten the cap (1) securely.

REMARK

If purified water is added to above the bottom tip of the sleeve, use a syringe to remove electrolyte. Neutralize

the removed electrolyte with baking soda (sodium bicarbonate), then flush it away with a large amount of water.

If necessary, consult your Komatsu distributor or your battery manufacturer.

METHOD FOR CHECKING AND ADJUSTING AIR CONDITIONER COMPRESSOR

BELT TENSION

In the event of abnormal belt noise, contact the Komatsu distributor for control and adjustment.

OUTRIGGERS AND BLADE PINS LUBRICATION METHOD

NOTICE

If any unusual noise is generated from any greasing point, perform the greasing regardless of the

greasing interval.

Perform the greasing every 10 hours for the first 50 hours of operation on a new machine.

After the machine is subjected to digging work in the water, be sure to grease the wet pins.

Prepare a grease pump.

RKA65320

RKA65330

MAINTENANCE PROCEDURE

MAINTENANCE

4-40

WENAM00130

Summary of Contents for PW118MR-11

Page 2: ......

Page 9: ...Do not repeatedly handle and lift loads FOREWORD VIBRATION LEVEL 1 7 WENAM00130...

Page 22: ...WENAM00130...

Page 25: ...LOCATION OF SAFETY LABELS RKA64590 SAFETY SAFETY LABELS 2 3 WENAM00130...

Page 72: ...WENAM00130...

Page 74: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA61930 GENERAL VIEW OPERATION 3 2 WENAM00130...

Page 77: ...CONTROLS AND GAUGES NAMES RKA62690 OPERATION GENERAL VIEW 3 5 WENAM00130...

Page 168: ...SWITCHES RKA63060 EXPLANATION OF COMPONENTS OPERATION 3 96 WENAM00130...

Page 328: ...WENAM00130...

Page 412: ...WENAM00130...

Page 413: ...SPECIFICATIONS 5 1 WENAM00130...

Page 445: ...REPLACEMENT PARTS 7 1 WENAM00130...

Page 461: ......

Page 462: ......