If necessary, for precise control, perform small movements

with the machine to the correct position.

2.

Visually check that the oil level is up to the hole (2).

3.

If necessary, top-up through the level hole (2).

Use a 12 mm wrench.

METHOD FOR CHECKING THE OIL LEVELS IN THE TRANSMISSION REDUC-

TION GEAR

k

k

WARNING

Immediately after the engine is stopped, its parts and oil are still very hot and may cause burn injury.

Accordingly, wait until they have cooled down before starting the work.

For the check, position the machine on solid flat ground, place the equipment on the ground and stop the en-

gine.

1.

Check visually that the lubricant reaches the hole (1).

2.

If necessary, restore the level through the hole (1).

Use a 17 mm wrench

EVERY 500 HOURS MAINTENANCE

Maintenance for every 100 and 250 hours should be performed at the same time.

METHOD FOR LUBRICATING WORK EQUIPMENT

NOTICE

If any unusual noise is generated from any greasing point, perform the greasing regardless of the

greasing interval.

Perform the greasing every 10 hours for the first 50 hours of operation on a new machine.

After the machine is subjected to digging work in the water, be sure to grease the wet pins.

Prepare a grease pump.

1.

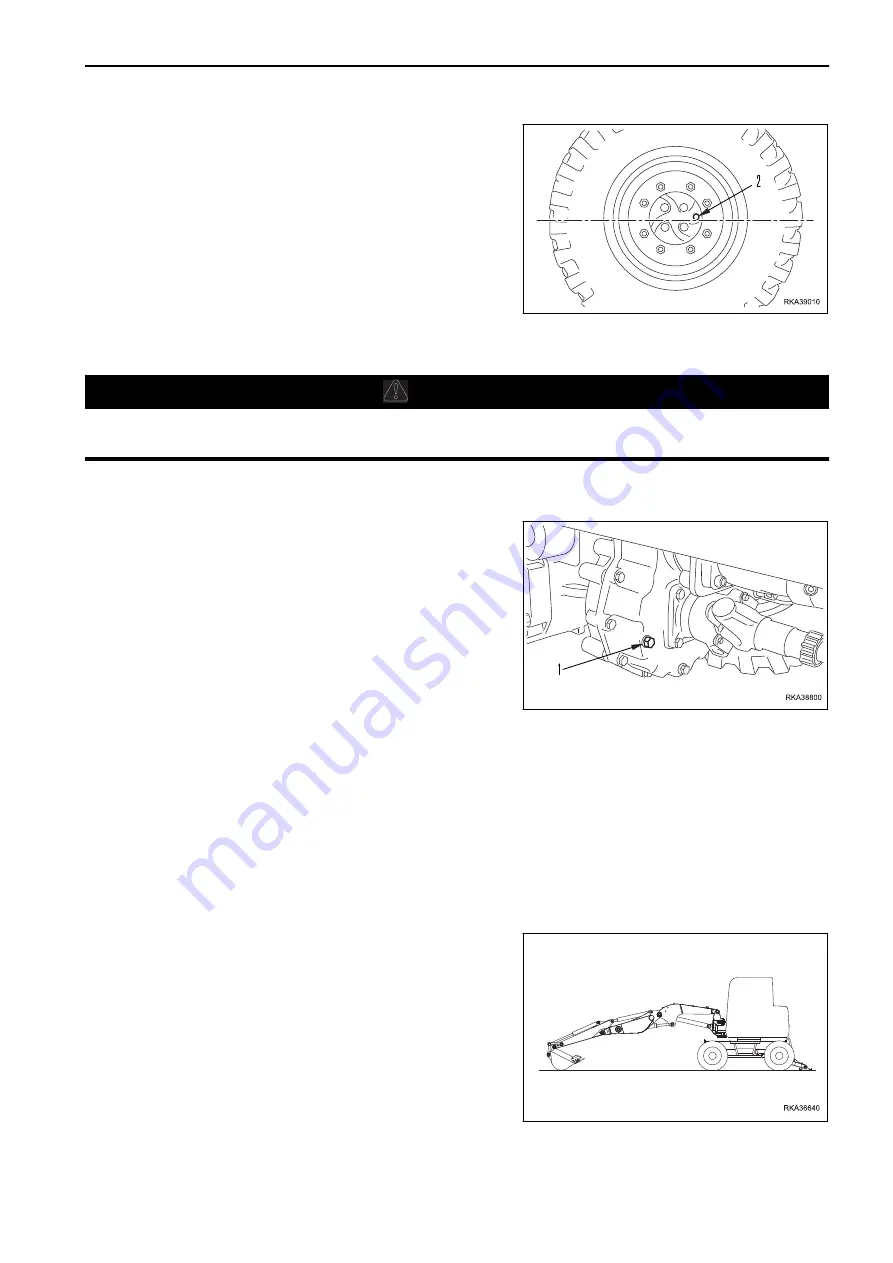

Set the machine to the greasing posture shown on the fig-

ure, lower the work equipment to the ground,and stop the

engine.

2.

By using a grease pump, pump in grease through the grease fitting shown by arrow.

(1) Boom base pin (2 points)

MAINTENANCE

MAINTENANCE PROCEDURE

4-43

WENAM00130

Summary of Contents for PW118MR-11

Page 2: ......

Page 9: ...Do not repeatedly handle and lift loads FOREWORD VIBRATION LEVEL 1 7 WENAM00130...

Page 22: ...WENAM00130...

Page 25: ...LOCATION OF SAFETY LABELS RKA64590 SAFETY SAFETY LABELS 2 3 WENAM00130...

Page 72: ...WENAM00130...

Page 74: ...GENERAL VIEW MACHINE EQUIPMENT NAME RKA61930 GENERAL VIEW OPERATION 3 2 WENAM00130...

Page 77: ...CONTROLS AND GAUGES NAMES RKA62690 OPERATION GENERAL VIEW 3 5 WENAM00130...

Page 168: ...SWITCHES RKA63060 EXPLANATION OF COMPONENTS OPERATION 3 96 WENAM00130...

Page 328: ...WENAM00130...

Page 412: ...WENAM00130...

Page 413: ...SPECIFICATIONS 5 1 WENAM00130...

Page 445: ...REPLACEMENT PARTS 7 1 WENAM00130...

Page 461: ......

Page 462: ......