MACHINES READY FOR ATTACHMENTS

OPTIONS, ATTACHMENTS

320

PW160-7H VEAM390100

OPERATION

WARNING

●

Be careful when pressing the switch in the deceleration

range. The engine speed will rise suddenly.

●

Do not press the switch except when operating the

attachment. If the switch is depressed by accident, the

attachment may move suddenly and cause serious dam-

age or injury.

The operation of the attachment is as follows.

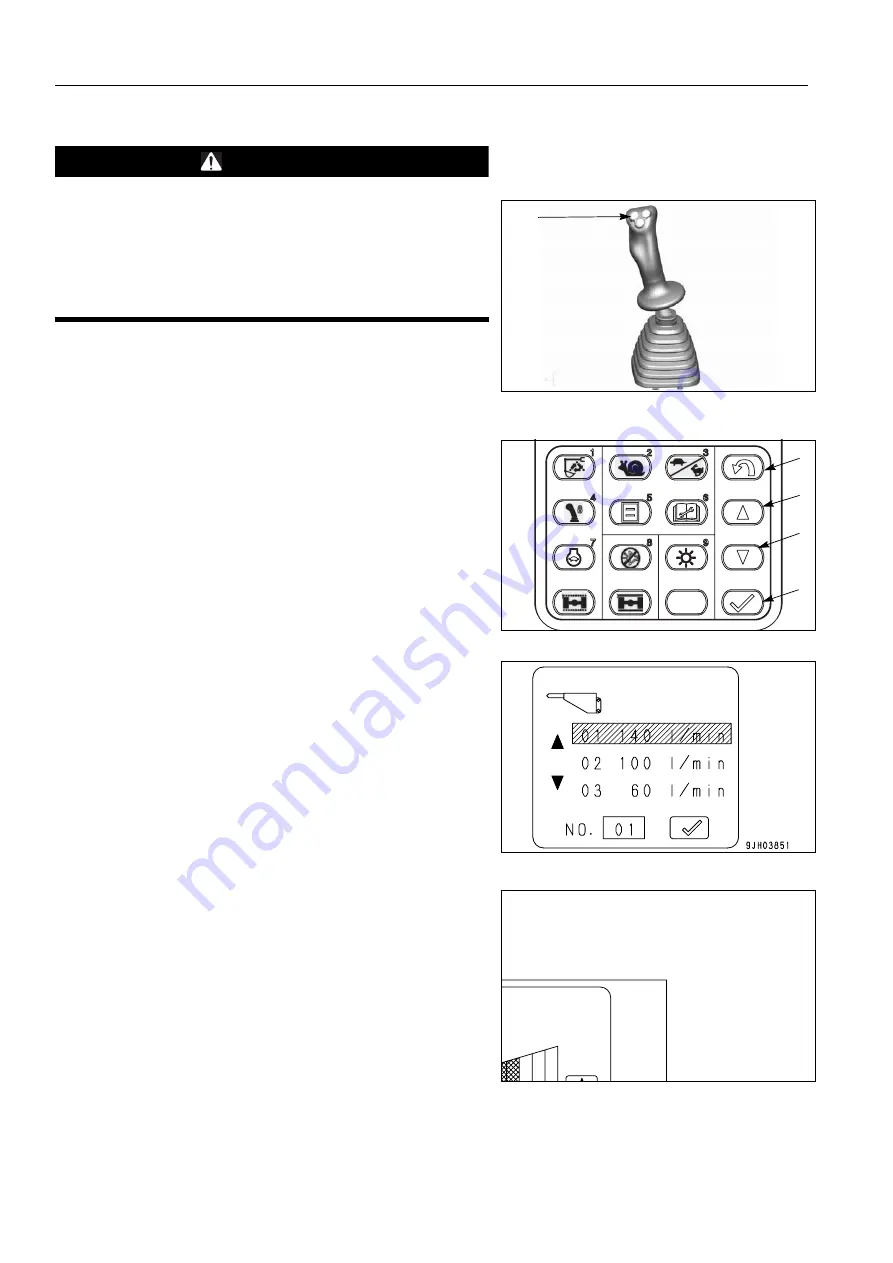

When the B mode control switch is ON if the button (2) is

depressed, the breaker is actuated.

1.

Set the working mode to B mode.

2.

When menu select switch (5) on the monitor is pressed, the

screen changes to screen (A). Select a suitable oil flow for the

breaker from among 140 litres/min, 100 litres/min, and 60

litres/min, then press input confirmation switch (12).

3.

The monitor screen changes to screen (B), so if it is neces-

sary to make fine adjustment, press up switch (14) or down

switch (13) to move the bar graph showing the oil flow up or

down, then press input confirmation switch (12).

●

It is possible to change the oil flow in segments of approx. 10

litres/min.

●

If fine adjustment is not necessary, simply press input confir-

mation switch (12).

●

The default setting is 140 litres/min.

●

Even if the starting switch is turned OFF, the set oil flow when

the engine is next started will be the value set by the above

procedure.

Precautions when using

●

Check that the stop valve is at the FREE position.

●

Check that the selector valve is in the position for using the

breaker and check that working mode is in B mode.

●

When considering whether it is necessary to install an accu-

mulator for the attachment circuit, contact the attachment

manufacturer and then decide.

●

For other precautions when handling the breaker, follow the

instruction manual from the breaker manufacturer and use

the breaker correctly.

●

The deterioration of the hydraulic oil when using the breaker

is much faster than for normal operations, so reduce the

maintenance interval for the hydraulic oil and element.

For details, see "MAINTENANCE SCHEDULE CHART

(240)".

2

15

13

14

12

A

Summary of Contents for PW160-7H

Page 2: ......

Page 3: ...PW160 7H VEAM390100 3 FOREWORD ...

Page 12: ...LOCATIONS OF PLATES TABLE TO ENTER SERIAL NO AND DISTRIBUTOR FOREWORD 12 PW160 7H VEAM390100 ...

Page 18: ...18 PW160 7H VEAM390100 ...

Page 220: ...TROUBLESHOOTING OPERATION 220 PW160 7H VEAM390100 ...

Page 305: ...PW160 7H VEAM390100 305 SPECIFICATIONS ...

Page 307: ...SPECIFICATIONS SPECIFICATIONS PW160 7H VEAM390100 307 1 PIECE BOOM ...

Page 308: ...SPECIFICATIONS SPECIFICATIONS 308 PW160 7H VEAM390100 2 PIECE BOOM ...

Page 345: ......