Transportation

OPERATION

Transportation procedure

3-98

Transportation

0.

When transporting the machine, observe all related laws and regulations, and be careful to assure safety.

Transportation procedure

0.

As a basic rule, always transport the machine on a trailer.

When selecting the trailer, see the weights and dimensions given in section “Technical data on page 5-2“.

Note that the specifications for the weights and dimensions for transportation differ according to the type of tires

and type of bucket.

Loading, unloading work with trailers

0.

WARNING

When loading or unloading the machine, run the engine at low speed, travel at low speed, and operate

slowly.

When loading or unloading the machine, stop the trailer on firm level ground.

In addition, keep well away from the road shoulder.

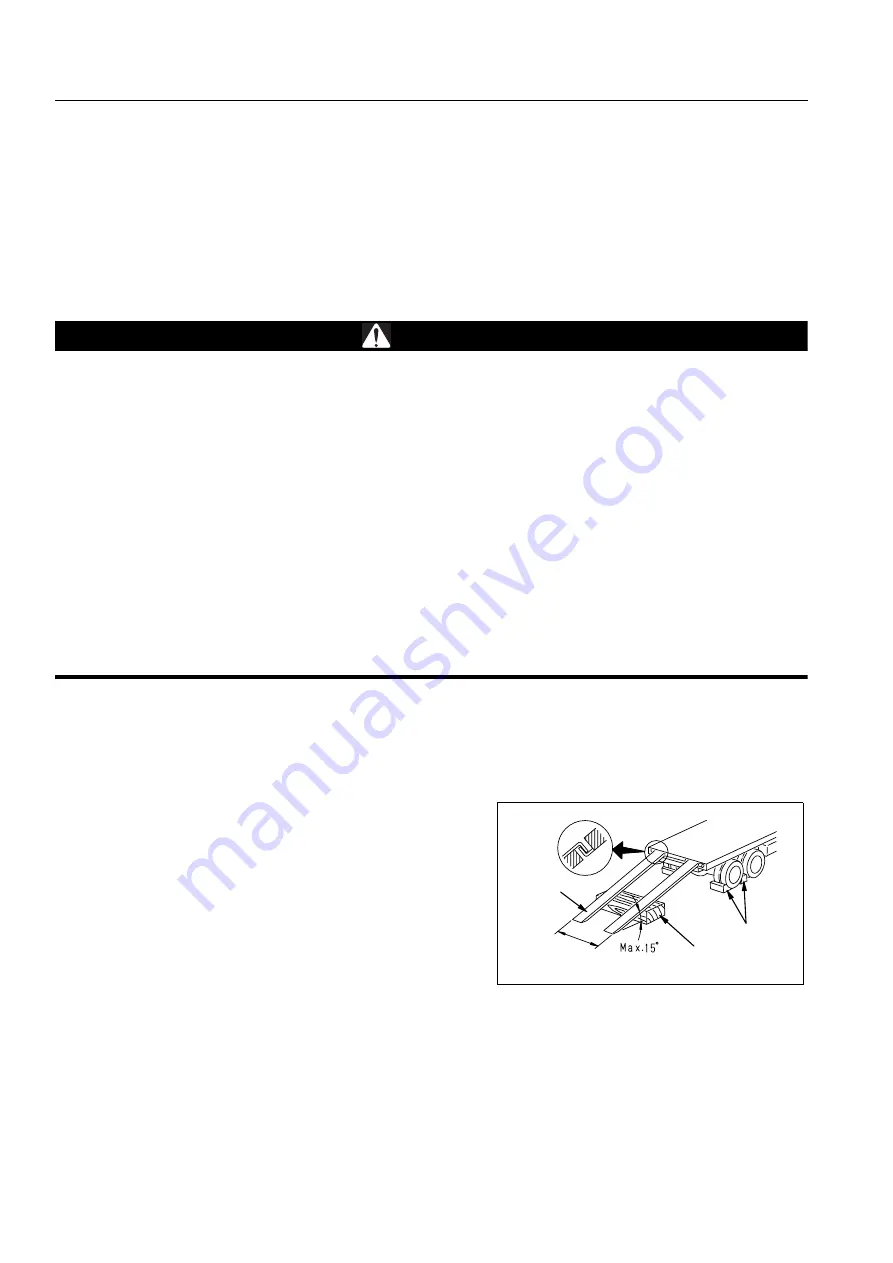

Use ramps of ample width, length, thickness, and strength, and install them securely at an angle of

less than 15°.

When using an embankment, compact the fill soil thoroughly and make sure that the slope face does

not collapse.

Remove the mud stuck to the undercarriage to prevent the machine from slipping to the side on the

ramps.

In addition, remove any water, snow, ice, grease, or oil from the ramps.

Never change direction on the ramps. There is danger that the machine may tip over.

If it is necessary to change direction, return to the ground surface or the trailer platform, correct the

direction, and start again.

The position of the center of gravity of the machine will change suddenly at the connection of the

ramp and trailer, and there is danger of the machine losing its balance. Always drive slowly over this

point.

When loading or unloading, always use ramps or a platform and carry out the operation as follows.

Loading

0.

1. Load and unload on firm level ground only.

Maintain a safe distance from the edge of a road.

2. Apply the brakes on the trailer securely and insert blocks

under the tires to ensure that the trailer does not move.

Then fix the ramps in line with the centers of the trailer and

the machine.

Be sure that the two sides are at the same height as one

another.

Make the angle of the ramps a maximum of 15º.

Set the distance between the ramps to match the center of

the tires.

If the ramp sags appreciably, reinforce it with blocks, etc.

3. Determine the direction of the ramp, then slowly load the

machine.

4. Load the machine correctly in the specified position on the

trailer.

9ER01312A

Blocks

Block

Ramp

Distance

between ramps

Summary of Contents for WA250PT-5H

Page 2: ......

Page 3: ...FOREWORD 11...

Page 16: ...Contents FOREWORD 1 14...

Page 24: ...SAFETY 2 2...

Page 58: ...Precautions with tires SAFETY Precautions when storing tires 2 36...

Page 60: ...OPERATION 3 2...

Page 233: ...TECHNICAL DATA 45...

Page 235: ...TECHNICAL DATA Technical data 5 3...

Page 250: ...Central lubrication system ATTACHMENTS OPTIONS 6 14...

Page 251: ...INDEX 67...

Page 252: ...INDEX 7 2...

Page 255: ...Index 7 5...