Service procedure

MAINTENANCE

When required

4-24

Clean inside of cooling system

0.

WARNING

Immediately after the engine is stopped, the engine coolant is hot and the pressure inside the radia-

tor is high. Removing the cap and draining the water under this condition could cause burns. Allow

the engine to cool down, then turn the cap slowly to release the pressure. To top up coolant in the

radiator, use a suitable climbing aid (for example a ladder) to climb up the back of the machine. Slowly

loosen the sealing cap to let off the pressure.

Start the engine and flush the system. When standing up or leaving the operator's seat, set the safety

lock lever to the LOCK position.

For details of starting the engine, see “Check before starting engine, adjust on page 3-54“ and “Start-

ing engine on page 3-68“ in the OPERATION section of the Operation and Maintenance Manual.

When the undercover is removed, there is danger of touching the fan.

Never go to the rear of the machine when the engine is running.

Clean the inside of the cooling system, change the coolant and replace the corrosion resistor according to the

table below.

Stop the machine on level ground when cleaning or changing the coolant.

Use a permanent type of antifreeze.

If, for some reason, it is impossible to use permanent type antifreeze, use an antifreeze containing ethylene glycol.

Super Coolant (AF-ACL) has an anti-corrosion effect as well as an antifreeze effect.

The ratio of antifreeze to water depends on the ambient temperature, but to obtain the corrosion resistance effect,

a minimum ratio of 30% by volume is necessary.

In areas where the water is hard, always add Komatsu genuine corrosion resistor agent KI. One packet of corro-

sion resistor agent (No. 600-411-1120) contains 100g (0.22 lb). The standard density of the mixture should be 7g/

liter (0.065 oz/US gal).

When deciding the ratio of antifreeze to water, check the lowest temperature in the past, and decide from the mix-

ing rate table given below.

It is actually better to estimate a temperature about 10°C (50°F) lower when deciding the mixing rate.

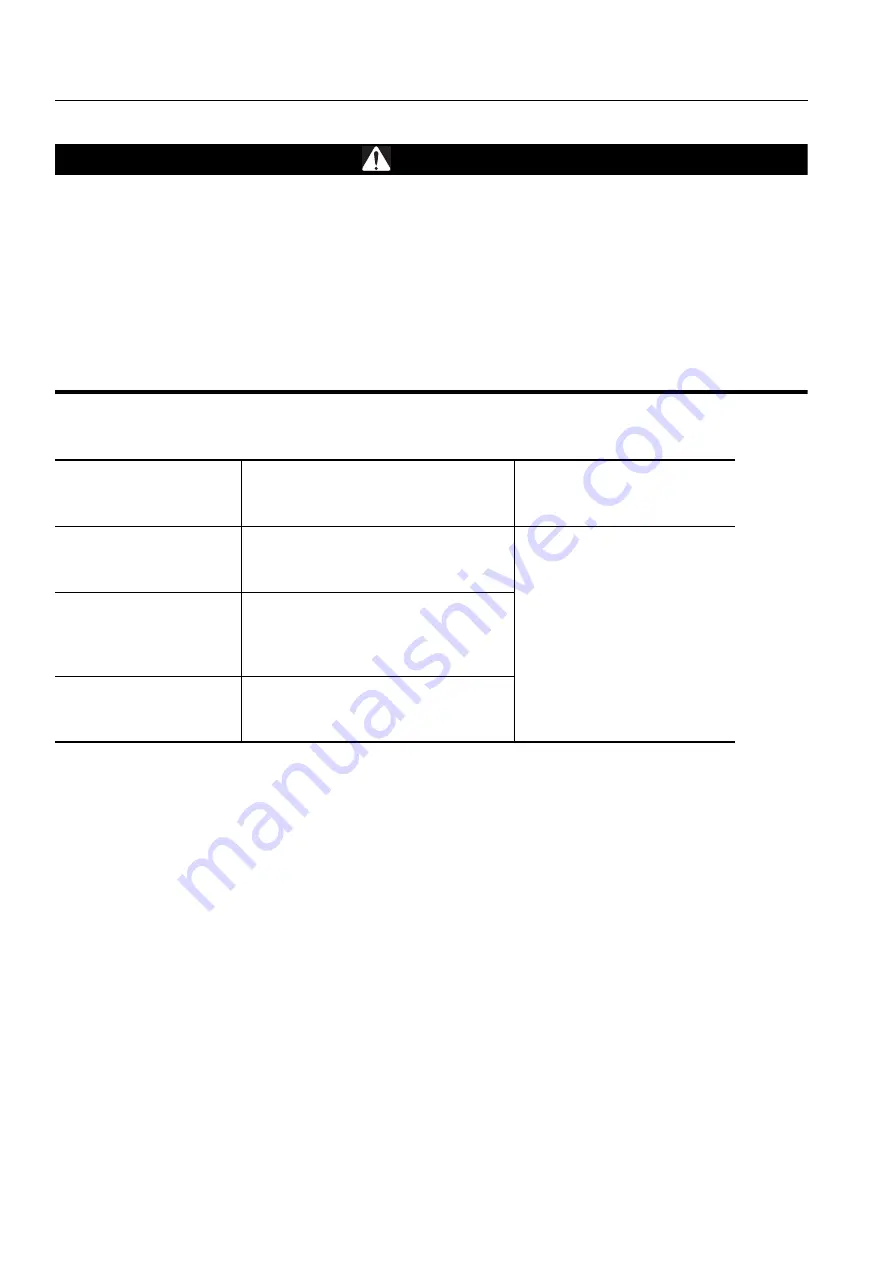

Kind of coolant

Cleaning inside of

cooling system and

changing coolant

Adding corrosion

resistor agent KI

Permanent type anti-

freeze

(All season type)

Every year (autumn) or

every 2000 hours

whichever comes first

Every 1000 hours and

when cleaning the inside

of the cooling system and

when changing coolant.

Non-permanent type

antifreeze containing

ethylene glycol (winter,

one season type)

Every 6 months (spring

and autumn)

(Drain antifreeze in spring,

add antifreeze in autumn)

When not using anti-

freeze

Every 6 months or every

1000 hours whichever

comes first

Summary of Contents for WA250PT-5H

Page 2: ......

Page 3: ...FOREWORD 11...

Page 16: ...Contents FOREWORD 1 14...

Page 24: ...SAFETY 2 2...

Page 58: ...Precautions with tires SAFETY Precautions when storing tires 2 36...

Page 60: ...OPERATION 3 2...

Page 233: ...TECHNICAL DATA 45...

Page 235: ...TECHNICAL DATA Technical data 5 3...

Page 250: ...Central lubrication system ATTACHMENTS OPTIONS 6 14...

Page 251: ...INDEX 67...

Page 252: ...INDEX 7 2...

Page 255: ...Index 7 5...