Service procedure

MAINTENANCE

When required

4-28

Check axle oil level, add oil

0.

WARNING

When checking the oil level, apply the parking brake and secure the front and rear frames with the

safety bar.

After stopping the engine, the parts and oil are at a high temperature. Wait for the temperature to go

down before starting the operation.

Carry out this procedure if there is any sign of oil on the axle case.

Carry out the inspection with the machine on a horizontal road surface.

(If the road surface is at an angle, the oil level cannot be checked correctly.)

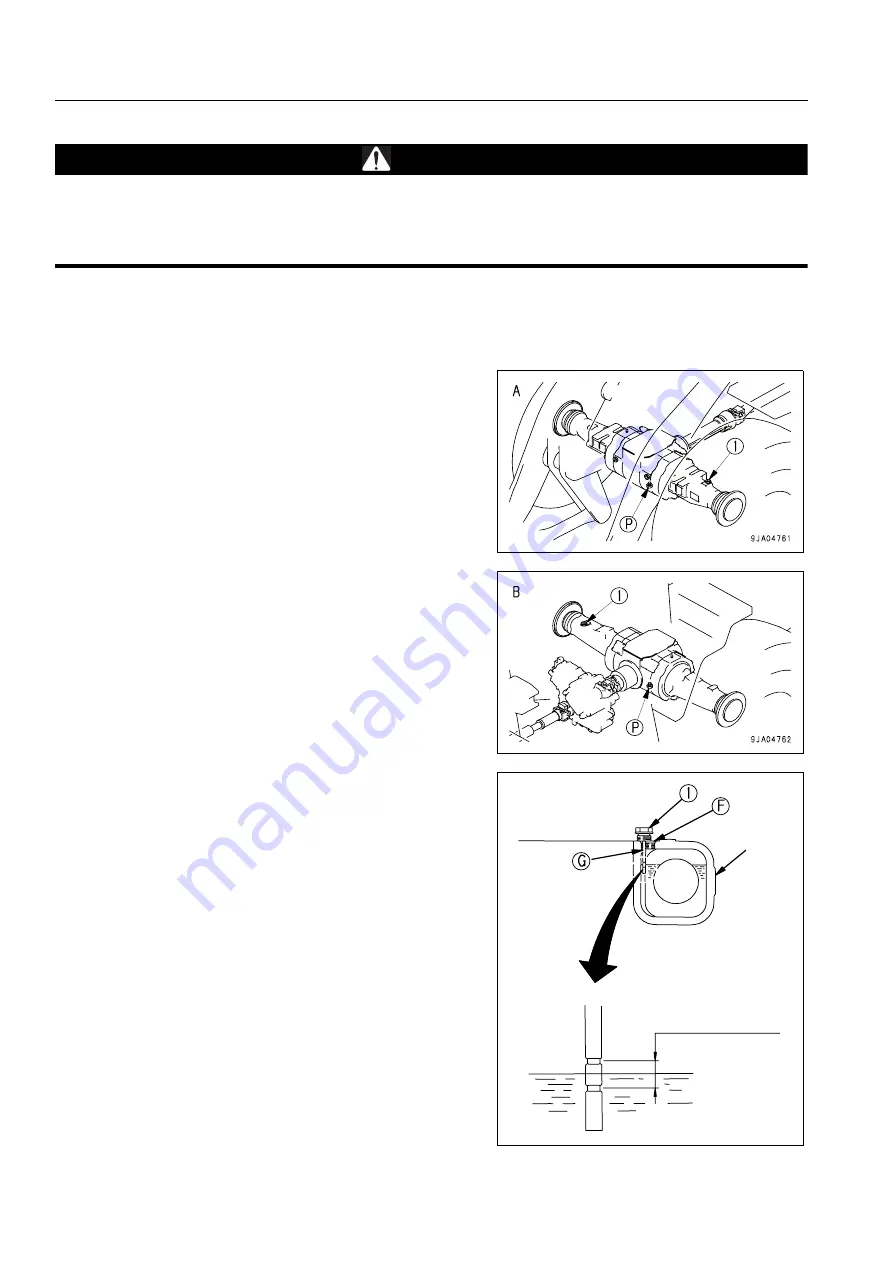

A: Front B: Rear

1. Stop the engine and remove oil level plug (1).

REMARK

Remove the mud and dirt from around plug (1), then

remove the plug.

2. Wipe off any oil adhering to the oil level gauge attached to

plug (1) with cloth.

3. Set the oil level gauge (G) as shown in the right diagram.

4. The oil level is correct when it is between the two lines pro-

vided on the oil level gauge.

If the oil level does not reach the lower line, add axle oil

through filler port (F).

5. If the oil level is above the upper line, drain off the excess oil

through drain plug (P) and check the oil level again.

6. If the oil level is correct, install plug (1).

Tightening torque: 108 ± 14.7 N·m (11 ± 1.5 kgf·m, 79.6 ±

10.8 lbft)

9EA04857A

Axle

assembly

Oil level

measuring location

(spot facing face)

Oil level range

Summary of Contents for WA250PT-5H

Page 2: ......

Page 3: ...FOREWORD 11...

Page 16: ...Contents FOREWORD 1 14...

Page 24: ...SAFETY 2 2...

Page 58: ...Precautions with tires SAFETY Precautions when storing tires 2 36...

Page 60: ...OPERATION 3 2...

Page 233: ...TECHNICAL DATA 45...

Page 235: ...TECHNICAL DATA Technical data 5 3...

Page 250: ...Central lubrication system ATTACHMENTS OPTIONS 6 14...

Page 251: ...INDEX 67...

Page 252: ...INDEX 7 2...

Page 255: ...Index 7 5...