MAINTENANCE

Service procedure

When required

4-31

Clean transfer oil cooler fins

0.

WARNING

If compressed air, high-pressure water, or steam hits your body directly or dirt is sent flying by the com-

pressed air, high-pressure water, or steam, there is danger of personal injury. Always wear protective

glasses, dust mask, and other protective equipment.

Clean the oil cooler if mud or dirt is stuck to it.

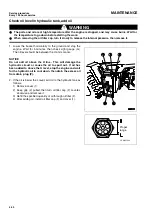

1. Remove cover (1).

2. Use compressed air to clean the mud, dust, and leaves

from the oil cooler fins (2). Steam or water may be used

instead of compressed air.

3. After cleaning, install the cover (1).

NOTICE

If the steam jet nozzle is brought too close to the oil cooler

fins, it may damage the fins, so keep the nozzle a suitable

distance away from the fins when cleaning.

Check electrical intake air heater

0.

Before the start of the cold season (once a year), contact your Komatsu distributor to have the electrical intake air

heater checked for dirt or disconnections.

Replace bolt on cutting edge

0.

WARNING

It is extremely dangerous if the work equipment moves when carrying out the turning or replacement

operation.

Set the work equipment in a stable position, stop the engine, then set the safety lock lever securely to the

LOCK position.

Turn or replace the cutting edge before the wear reaches the edge of the bucket.

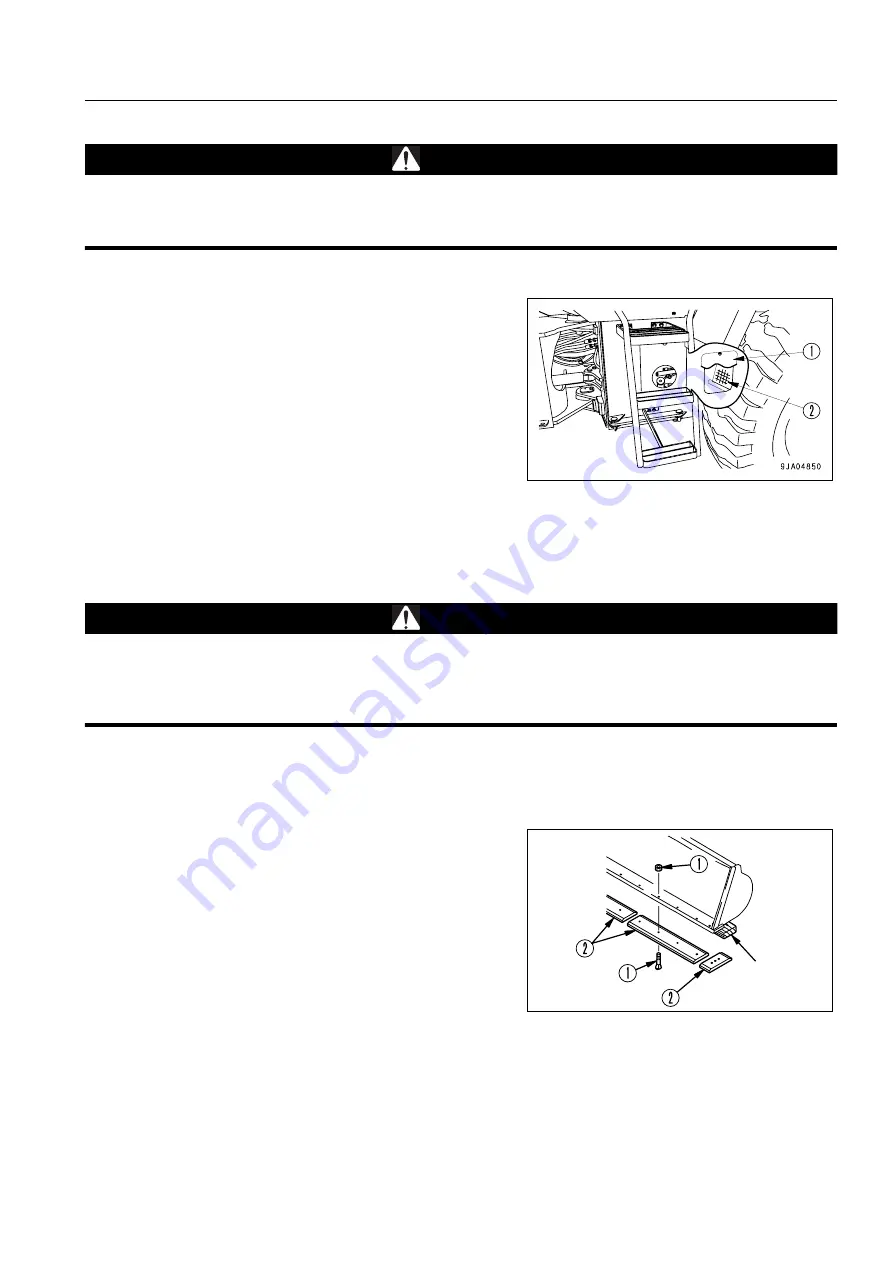

1. Raise the bucket to a suitable height, then put blocks under the bucket to prevent the bucket from coming

down.

Raise the bucket so that the bottom surface of the bucket is horizontal.

2. Remove nuts and bolts (1), then remove cutting edge (2).

3. Clean the mounting surface of cutting edge (2).

4. Turn cutting edge (2) and install it to the bucket. When turn-

ing the edge, install it to the opposite side (left edge to right

side, right edge to left side).

If both sides of the cutting edge are worn, replace with a

new part.

If the wear extends to the mounting surface, repair the

mounting surface before installing the cutting edge.

5. Tighten nuts and bolts (1) uniformly so that there is no gap

between the bucket and cutting edge.

Tightening torque for mounting bolt: 745 ± 108 N·m (76 ± 11

kgf·m, 549.7 ± 79.6 lbft)

6. Tighten the mounting bolts again after operating for several

hours.

9EW01519A

Block

Summary of Contents for WA250PT-5H

Page 2: ......

Page 3: ...FOREWORD 11...

Page 16: ...Contents FOREWORD 1 14...

Page 24: ...SAFETY 2 2...

Page 58: ...Precautions with tires SAFETY Precautions when storing tires 2 36...

Page 60: ...OPERATION 3 2...

Page 233: ...TECHNICAL DATA 45...

Page 235: ...TECHNICAL DATA Technical data 5 3...

Page 250: ...Central lubrication system ATTACHMENTS OPTIONS 6 14...

Page 251: ...INDEX 67...

Page 252: ...INDEX 7 2...

Page 255: ...Index 7 5...