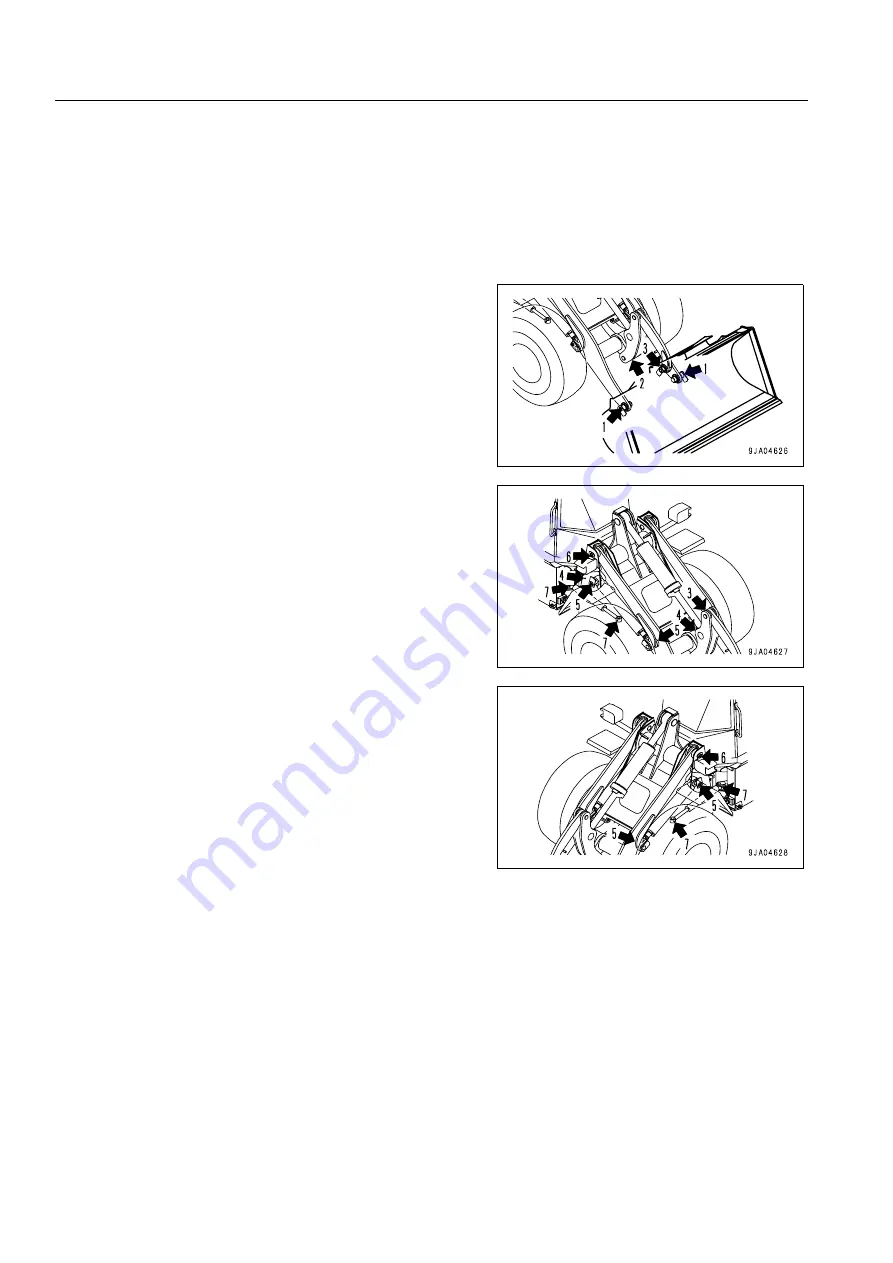

Service procedure

MAINTENANCE

Every 250 hours service

4-46

Lubricating

0.

1. Using a grease pump, pump in grease through the grease fittings marked by the arrows.

2. After greasing, wipe off any old grease that was pushed out.

NOTICE

On jobsites where there is a lot of heavy-duty work, or on jobsites where operations are carried out contin-

uously for more than eight hours, reduce the greasing interval and carry out greasing more frequently.

(1) Bucket pin (2 places)

(2) Tilt lever pin (1 place)

(3) Bucket link pin (2 places)

(4) Dump cylinder pin (2 places)

(5) Lift cylinder pin (4 places)

(6) Lift arm pivot pin (2 places)

(7) Steering cylinder pin (4 places)

Summary of Contents for WA250PT-5H

Page 2: ......

Page 3: ...FOREWORD 11...

Page 16: ...Contents FOREWORD 1 14...

Page 24: ...SAFETY 2 2...

Page 58: ...Precautions with tires SAFETY Precautions when storing tires 2 36...

Page 60: ...OPERATION 3 2...

Page 233: ...TECHNICAL DATA 45...

Page 235: ...TECHNICAL DATA Technical data 5 3...

Page 250: ...Central lubrication system ATTACHMENTS OPTIONS 6 14...

Page 251: ...INDEX 67...

Page 252: ...INDEX 7 2...

Page 255: ...Index 7 5...