3-29

MAINTENANCE EVERY 250 OPERATING HOURS

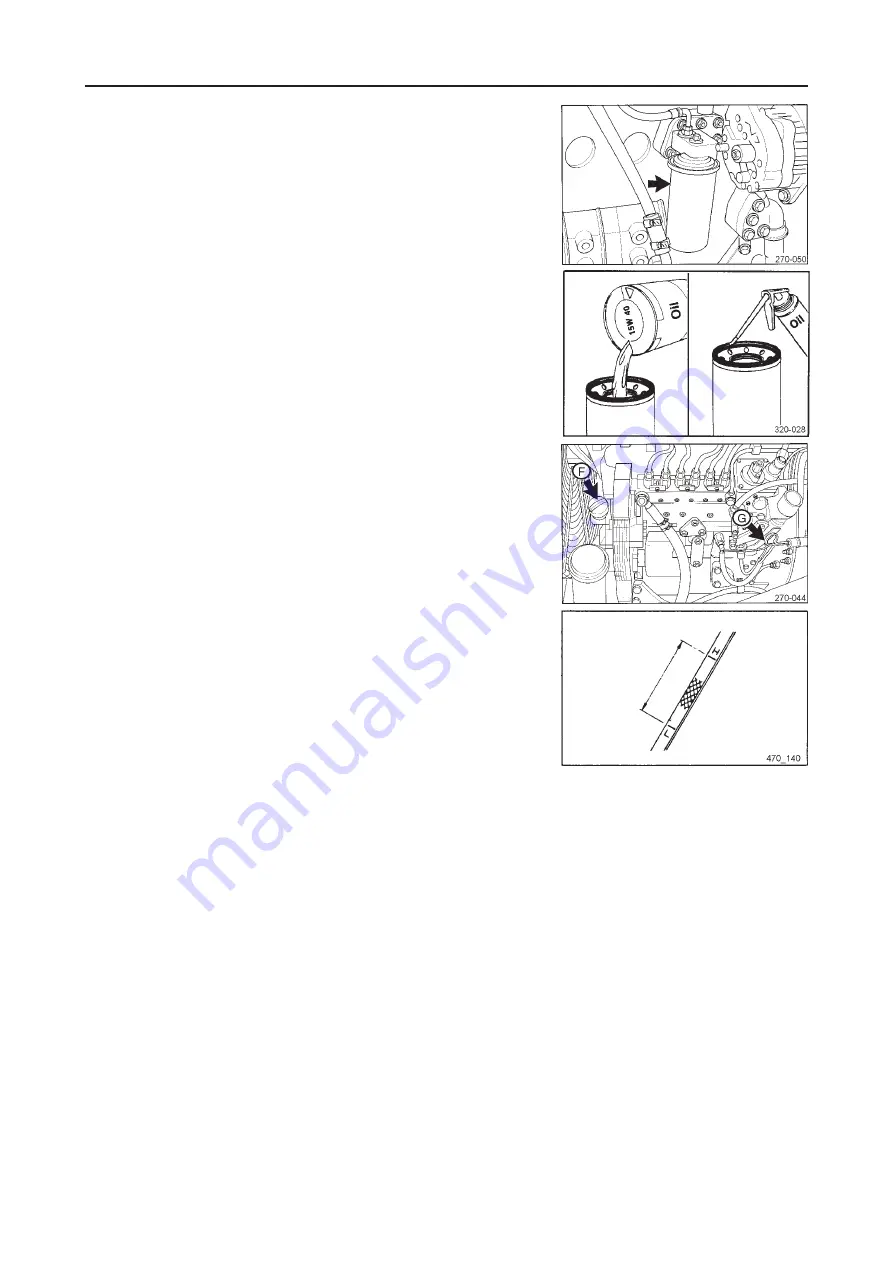

CHECKING THE AIR ASPIRATION SYSTEM

Check the air aspiration lines for damaged hoses, loose hose

clamps and holes, which could result in damage to the engine.

If necessary, tighten or replace components to ensure that the air

aspiration system has no leaks.

8.

Using a filter wrench, unscrew the filter cartridge anti-clockwise

on the left-hand side of the machine.

9.

Clean the filter support. Fill up the new filter cartridge with engine

oil. Oil the seal and thread of the cartridge slightly with engine oil

(or apply a thin coat of grease). Re-insert the filter cartridge and

tighten it.

10.

The sealing surface of the cartridge must rest lightly against the

filter support first when installing. Then, tighten the filter cartridge,

as specified in the instructions of the filter manufacturer.

11.

After replacing the filter cartridge, pour fresh engine oil into the

filler inlet (F) until the oil level has reached the marking (H) on the

dipstick.

Information on recommended oils, see section

"LUBRICANTS AND OPERATING AGENTS".

12.

Let the engine run idle for a short period, then switch it off and

check the oil level.

Further details, see section

"MAINTENANCE PRIOR TO STARTING UP"

Summary of Contents for WA270-3H

Page 2: ......

Page 10: ...0 8 Contents ...

Page 11: ...INFORMATION ON THESE OPERATING INSTRUCTIONS ...

Page 12: ...0 1 0 Information on these Operating Instructions ...

Page 22: ...0 2 0 Information on these Operating Instructions ...

Page 23: ...0 2 1 Loading and Transporting the Machine LOADING AND TRANSPORTING THE MACHINE ...

Page 24: ...0 2 2 Loading and Transporting the Machine ...

Page 30: ...0 2 8 Loading and Transporting the Machine ...

Page 56: ...SAFETY LABELS 1 26 ...

Page 58: ...SAFETY LABELS 1 28 ...

Page 59: ...2 1 Operating and Control Elements OPERATING AND CONTROL ELEMENTS ...

Page 72: ...2 14 Operating and Control Elements SWITCHES ...

Page 91: ...2 33 Operation OPERATION ...

Page 123: ...2 65 Troubleshooting TROUBLESHOOTING ...

Page 137: ...3 1 MAINTENANCE ...

Page 138: ...3 2 MAINTENANCE BASICS ...

Page 152: ...3 16 LUBRICANTS AND OPERATING AGENTS ...

Page 195: ...Technical details 4 1 TECHNICAL DETAILS ...

Page 198: ...Technical details 4 4 NOTES ...

Page 199: ...Special equipment auxiliary equipment 5 1 SPECIAL EQUIPMENT AUXILIARY EQUIPMENT ...

Page 202: ...Special equipment auxiliary equipment 5 4 ...

Page 203: ... 2001 Komatsu Hanomag Aktiengesellschaft All Rights Reserved Printed in Europe 02 2001 ...