3-36

MAINTENANCE EVERY 500 OPERATING HOURS

DANGER

The fuel inside the injection system is under pressure. Fuel

which is splashing out can penetrate the skin and lead to blood

poisoning.

Wear protective goggles and rubber gloves, when working on

the injection pump. If you are hit by a high-pressure stream of

fuel, immediately go to see a doctor and describe what has

happened.

BLEEDING THE FUEL SYSTEM

Have a container ready to collect fuel.

1.

Park and secure the machine as described in chapter "Preparing

the Machine for Maintenance", before performing maintenance

measures.

2.

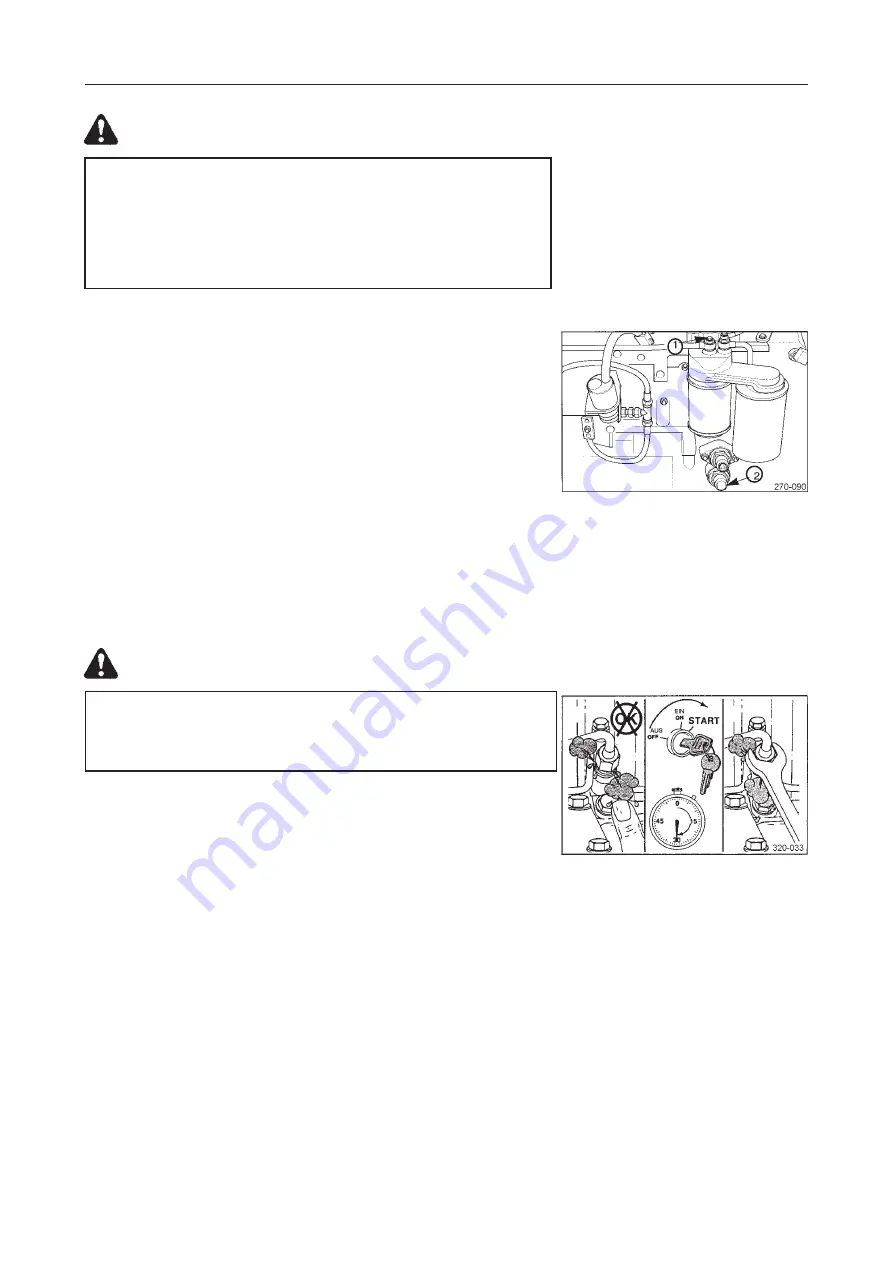

Loosen the bleed screw (1).

3.

Activate the pump (2) until fuel emerges from the bleed screw

which is bubblefree.

4.

Retighten the bleed screw.

5.

Activate pump several times to bleed the injection pump.

6.

Loosen the injection lines, one after the other, at the noozle holders.

7.

Turn the engine using the starter until all air has emerged from the

injection lines. Do not activate the starter for longer than 20 seconds

without interruption.

8.

Reconnect and retighten all connections

WARNING

If the engine is running, be careful not to get injured by the

moving parts of the engine compartment.

Do not perform actions in the engine compartment while the

engine is running.

9.

Start the engine and carefully bleed the lines again, one after the

other, with the engine running until the engine runs smoothly.

IMPORTANT

If the fuel system has run empty during driving, or if repairs or

maintenance tasks have been performed on it, it is required to bleed

the system.

Summary of Contents for WA270-3H

Page 2: ......

Page 10: ...0 8 Contents ...

Page 11: ...INFORMATION ON THESE OPERATING INSTRUCTIONS ...

Page 12: ...0 1 0 Information on these Operating Instructions ...

Page 22: ...0 2 0 Information on these Operating Instructions ...

Page 23: ...0 2 1 Loading and Transporting the Machine LOADING AND TRANSPORTING THE MACHINE ...

Page 24: ...0 2 2 Loading and Transporting the Machine ...

Page 30: ...0 2 8 Loading and Transporting the Machine ...

Page 56: ...SAFETY LABELS 1 26 ...

Page 58: ...SAFETY LABELS 1 28 ...

Page 59: ...2 1 Operating and Control Elements OPERATING AND CONTROL ELEMENTS ...

Page 72: ...2 14 Operating and Control Elements SWITCHES ...

Page 91: ...2 33 Operation OPERATION ...

Page 123: ...2 65 Troubleshooting TROUBLESHOOTING ...

Page 137: ...3 1 MAINTENANCE ...

Page 138: ...3 2 MAINTENANCE BASICS ...

Page 152: ...3 16 LUBRICANTS AND OPERATING AGENTS ...

Page 195: ...Technical details 4 1 TECHNICAL DETAILS ...

Page 198: ...Technical details 4 4 NOTES ...

Page 199: ...Special equipment auxiliary equipment 5 1 SPECIAL EQUIPMENT AUXILIARY EQUIPMENT ...

Page 202: ...Special equipment auxiliary equipment 5 4 ...

Page 203: ... 2001 Komatsu Hanomag Aktiengesellschaft All Rights Reserved Printed in Europe 02 2001 ...