1 - 2 2

Safety Measures During Maintenance

HIGH-PRESSURE HOSES

Neither bend high-pressure hoses nor hit them with hard objects. Do not

use piping or hoses with fissures, cracks, or bends, since they may burst

during operation.

Immediately replace any loose or damaged fuel or oil hoses. Leaking

fuel or oil involves danger of fire and slipping.

Replace all hoses every six years at the latest.

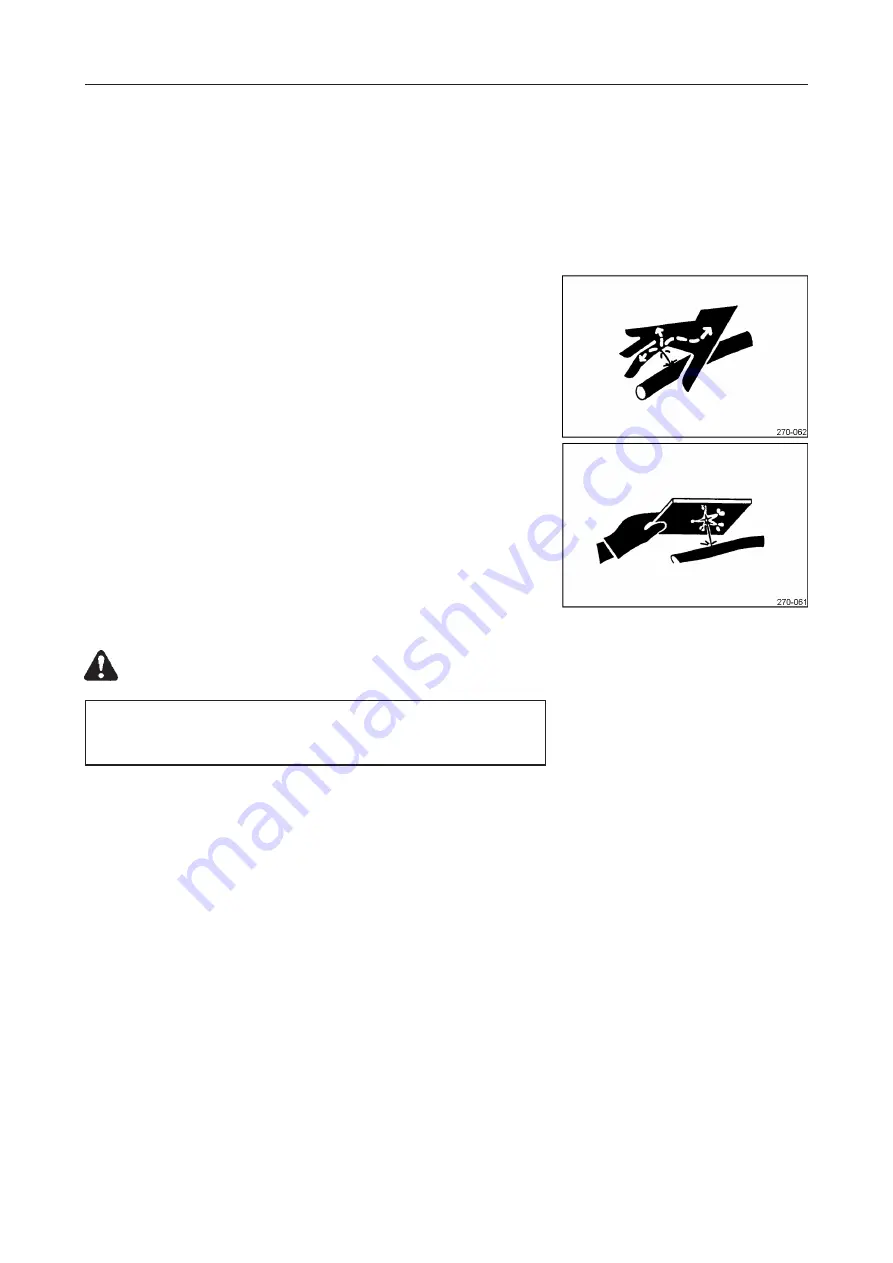

HANDLING HIGH-PRESSURE OIL

•

Always take into account that the hydraulic lines are subjected to high

pressure.

•

Do not top up oil, drain oil, or perform maintenance or inspection

measures unless the work unit is completely lowered and the system

is depressurised.

•

If oil comes out under high pressure, this involves danger of an oil jet

penetrating the skin or getting into the eyes. For this reason, always

wear safety goggles and thick safety gloves, and use a piece of

cardboard or wood when checking for oil leaks.

•

If you have been hit by an oil jet, immediately go and see a doctor and

explain what has happened.

HANDLING OF ALS-CONTROL PRESSURE ACCUMULATORS

WARNING

Danger of injury! Pressure accumulators are filled with highly

pressurised nitrogen.

Do not open or damage pressure accumulators.

•

Immediately inform your Komatsu dealer, if you detect malfunctions

or defects of pressure accumulators.

•

Filling pressure accumulators with gas or topping up gas in pressure

accumulators is strictly limited to either Komatsu service technicians

or other persons authorised to handle highly pressurised gas.

•

Do not hit against the pressure accumulator.

•

Keep naked light and sources of heat away from pressure

accumulators.

•

Do not drill holes into the pressure accumulator.

•

Do not weld parts to the pressure accumulator.

•

The service technicians must depressurise the hydraulic system before

they can remove the pressure accumulators.

•

The service technician must let the gas escape before they can

disassemble the pressure accumulator.

•

Have the gas pressure of the pressure accumulators checked either

every 1000 operating hours or once every year.

NOTE

In countries with a hot climate, the responsible Komatsu dealer must

check the gas-pressure of the pressure reservoir already every 650

hours.

Summary of Contents for WA270-3H

Page 2: ......

Page 10: ...0 8 Contents ...

Page 11: ...INFORMATION ON THESE OPERATING INSTRUCTIONS ...

Page 12: ...0 1 0 Information on these Operating Instructions ...

Page 22: ...0 2 0 Information on these Operating Instructions ...

Page 23: ...0 2 1 Loading and Transporting the Machine LOADING AND TRANSPORTING THE MACHINE ...

Page 24: ...0 2 2 Loading and Transporting the Machine ...

Page 30: ...0 2 8 Loading and Transporting the Machine ...

Page 56: ...SAFETY LABELS 1 26 ...

Page 58: ...SAFETY LABELS 1 28 ...

Page 59: ...2 1 Operating and Control Elements OPERATING AND CONTROL ELEMENTS ...

Page 72: ...2 14 Operating and Control Elements SWITCHES ...

Page 91: ...2 33 Operation OPERATION ...

Page 123: ...2 65 Troubleshooting TROUBLESHOOTING ...

Page 137: ...3 1 MAINTENANCE ...

Page 138: ...3 2 MAINTENANCE BASICS ...

Page 152: ...3 16 LUBRICANTS AND OPERATING AGENTS ...

Page 195: ...Technical details 4 1 TECHNICAL DETAILS ...

Page 198: ...Technical details 4 4 NOTES ...

Page 199: ...Special equipment auxiliary equipment 5 1 SPECIAL EQUIPMENT AUXILIARY EQUIPMENT ...

Page 202: ...Special equipment auxiliary equipment 5 4 ...

Page 203: ... 2001 Komatsu Hanomag Aktiengesellschaft All Rights Reserved Printed in Europe 02 2001 ...