SERVICE PROCEDURE

MAINTENANCE

4-40

EVERY 100 HOURS SERVICE

4

Maintenance for every 50 hours service should be carried out at the same time.

LUBRICATE REAR AXLE PIVOT PIN

4

(3 places)

1.

Using a grease pump, pump in grease through the grease

fittings marked by the arrows.

2.

After greasing, wipe off any old grease that was pushed

out.

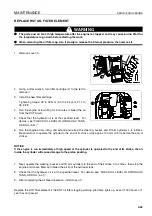

CLEAN ELEMENT IN AIR CONDITIONER FRESH AIR FILTER

4

WARNING

If compressed air is used, there is danger that dirt may fly and cause personal injury.

Always wear safety glasses, dust mask, and other protective equipment.

If the air conditioner has been used, the air filter should be cleaned.

Stop the air conditioner before cleaning the element.

1.

Open cover (1).

2.

Remove bracket (2) and filter (3) as one unit.

3.

Direct dry compressed air (less than 0.69 MPa (7 kgf/ cm2,

99.4 PSI)) to the element from inside along its folds, then

direct it from outside along its folds and again from inside.

4.

When installing, fit filter (3) into bracket (2), then install.

Summary of Contents for WA320-5H

Page 2: ...FOREWORD 11...

Page 17: ...CONTENTS FOREWORD 1 16...

Page 23: ...CE CONFORMING EQUIPMENT FOREWORD 1 22...

Page 24: ...SAFETY 12...

Page 25: ...SAFETY 2 2...

Page 60: ...OPERATION 13...

Page 181: ...TROUBLESHOOTING OPERATION 3 122...

Page 182: ...MAINTENANCE 14...

Page 243: ...SERVICE PROCEDURE MAINTENANCE 4 62...

Page 244: ...TECHNICAL DATA 15...

Page 246: ...TECHNICAL DATA TECHNICAL DATA 5 3...

Page 248: ...ATTACHMENTS OPTIONS 16...

Page 313: ...CENTRAL LUBRICATION SYSTEM ATTACHMENTS OPTIONS 6 66...

Page 314: ...INDEX 17...

Page 315: ...INDEX 7 2...

Page 318: ...NOTES 18...

Page 319: ...NOTES NOTES 8 2 NOTES 8...

Page 320: ...NOTES NOTES 8 3...

Page 321: ...2003 Komatsu Hanomag GmbH All Rights Reserved Printed in Europe 10 2003...