Operation

3.3 Operation

WA470-6H – VEAM946100

3-95

REMARK

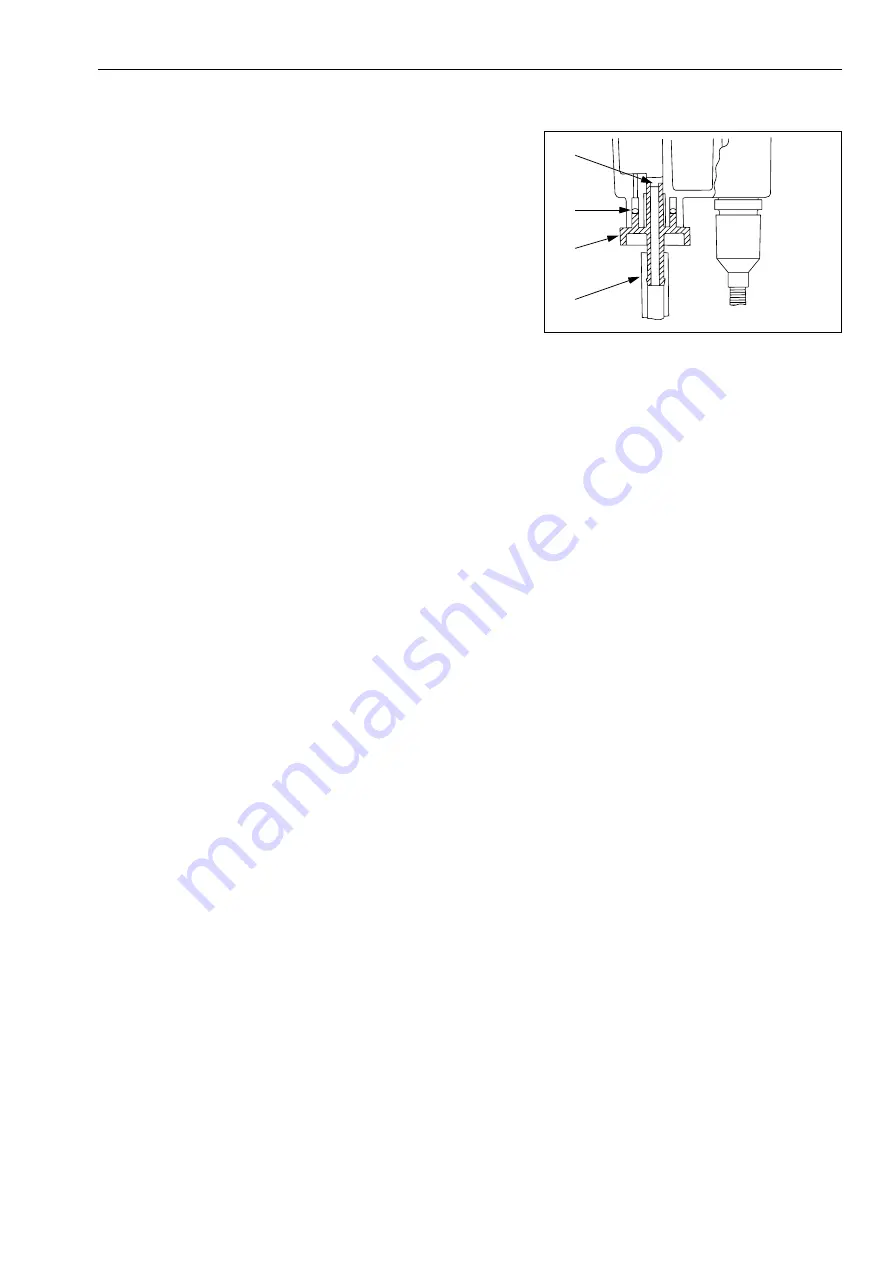

If plug (2) is stiff, coat O-ring (5) of plug (2) with grease.

1. Set a fuel container under drain hose (4).

2. Loosen plug (2), then drain all the sediment together with the

fuel from drain hose (4).

3. Check that nothing comes out from drain hose (4), then

remove plug (2).

4. Coat O-ring portion (5) with a suitable amount of grease.

When doing this, be careful not to let the grease get on the

drain valve water drain port (a) or the plug thread.

5. Screw in plug (2) by hand until it contacts the bottom.

6. Remove the fuel container.

If transparent cap (3) is dirty and the contents cannot be

easily seen, clean transparent cap (3) when replacing the fil-

ter.

When washing, if plug (2) is removed, coat the O-ring with

grease, then tighten by hand until it contacts the bottom.

GK038072

a

5

2

4

Summary of Contents for WA470-6 2006

Page 2: ......

Page 3: ...Foreword WA470 6H VEAM946100 1 1 1 Foreword...

Page 22: ...1 5 Contents Foreword 1 20 WA470 6H VEAM946100 7 Index 7 1 7 1 Index 7 2 8 Notes 8 1...

Page 28: ...1 7 CE Conforming equipment Foreword 1 26 WA470 6H VEAM946100...

Page 250: ...3 7 Troubleshooting Operation 3 178 WA470 6H VEAM946100...

Page 340: ...4 9 Service procedure Every 12000 hours service Maintenance 4 90 WA470 6H VEAM946100...

Page 341: ...Technical Data WA470 6H VEAM946100 5 1 5 Technical Data...

Page 343: ...Technical Data 5 1 Technical data WA470 6H VEAM946100 5 3 GK032301 A B H I G C E F D...

Page 348: ...5 4 Limit values for slopes Technical Data 5 8 WA470 6H VEAM946100...

Page 381: ...Index WA470 6H VEAM946100 7 1 7 Index...

Page 387: ...Notes WA470 6H VEAM946100 8 1 8 Notes...

Page 388: ...Notes 8 2 WA470 6H VEAM946100...

Page 389: ...Notes WA470 6H VEAM946100 8 3...

Page 390: ...Notes 8 4 WA470 6H VEAM946100...

Page 391: ...Notes WA470 6H VEAM946100 8 5...

Page 392: ...Notes 8 6 WA470 6H VEAM946100...