Operation

3.3 Operation

WA470-6H – VEAM946100

3-127

Locate the cause and do not operate the machine until it has

been repaired.

REMARK

If any function of the oil pressure system is used when the

engine is running at low speed, steering oil pressure caution

lamp (red) (3) may light up for a moment, but if the lamp goes

out again soon, there is no problem.

When the emergency steering system detects that the oil pres-

sure in the steering circuit has been restored, the actuation of

the emergency steering system is stopped.

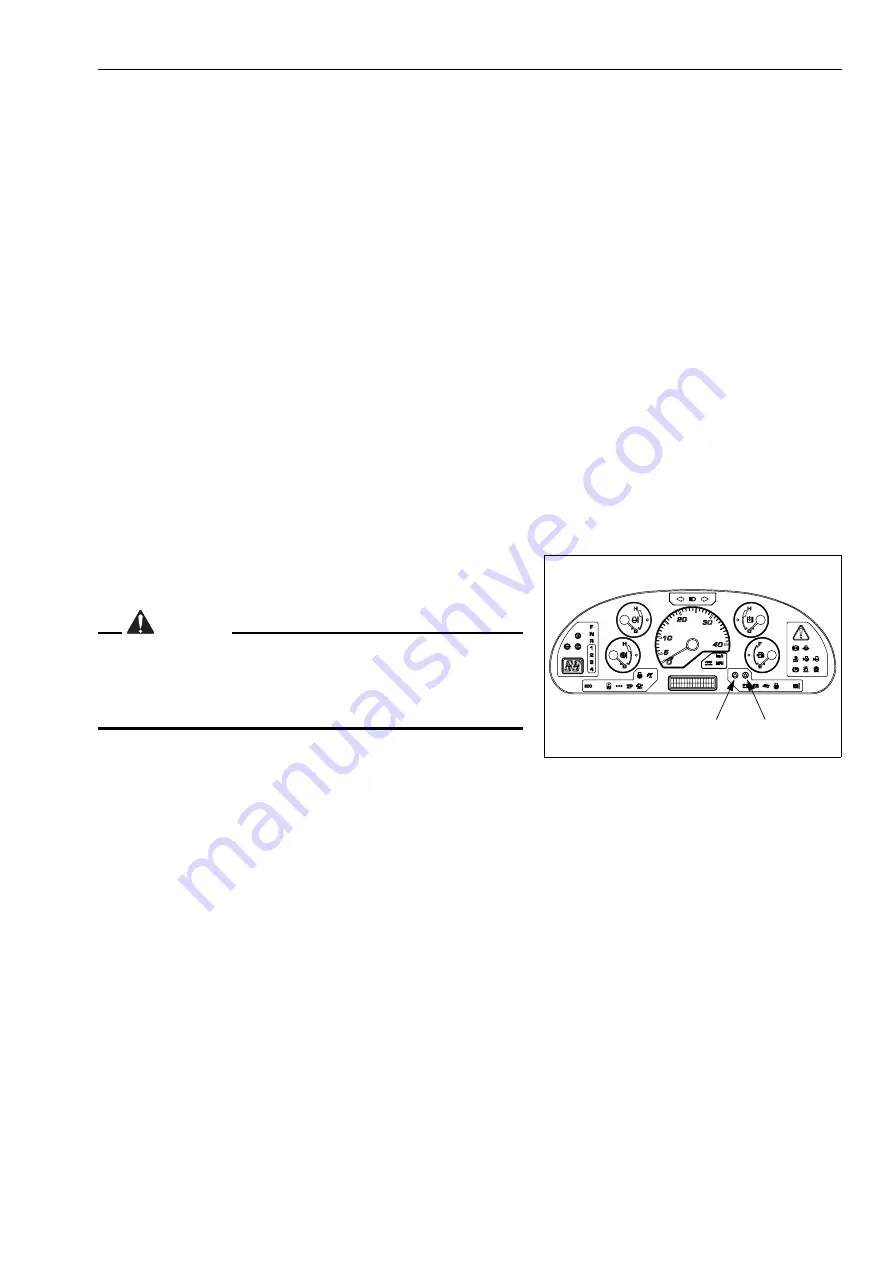

On machines equipped with an emergency steering function, the

emergency steering switch is installed at the position shown in

the diagram (1).

Emergency steering self-check function

When the starting switch is turned ON, the emergency steering

is automatically actuated for approx. 3 seconds to check that the

emergency steering is functioning properly.

When this happens, steering oil pressure caution lamp (red) (1)

and emergency steering pilot lamp (green) (2) light up.

CAUTION

!

If the machine is steered during the steering self-check, it

may move.

!

Do not steer the machine during the steering self-check.

The emergency steering function check is not carried out in the

following cases.

!

If the starting switch is turned ON, turned OFF again without

starting the engine, and is then turned ON again.

!

If the starting switch is turned ON again immediately after

stopping the engine when the steering oil pressure has not

gone down completely.

!

When preheating is being carried out.

When preheating is being carried out

When preheating is being carried out, the emergency steering

self- check function is not actuated.

To check the emergency steering function, press the emergency

steering switch after completing the warming-up operation.

GK038005

2

1

Summary of Contents for WA470-6 2006

Page 2: ......

Page 3: ...Foreword WA470 6H VEAM946100 1 1 1 Foreword...

Page 22: ...1 5 Contents Foreword 1 20 WA470 6H VEAM946100 7 Index 7 1 7 1 Index 7 2 8 Notes 8 1...

Page 28: ...1 7 CE Conforming equipment Foreword 1 26 WA470 6H VEAM946100...

Page 250: ...3 7 Troubleshooting Operation 3 178 WA470 6H VEAM946100...

Page 340: ...4 9 Service procedure Every 12000 hours service Maintenance 4 90 WA470 6H VEAM946100...

Page 341: ...Technical Data WA470 6H VEAM946100 5 1 5 Technical Data...

Page 343: ...Technical Data 5 1 Technical data WA470 6H VEAM946100 5 3 GK032301 A B H I G C E F D...

Page 348: ...5 4 Limit values for slopes Technical Data 5 8 WA470 6H VEAM946100...

Page 381: ...Index WA470 6H VEAM946100 7 1 7 Index...

Page 387: ...Notes WA470 6H VEAM946100 8 1 8 Notes...

Page 388: ...Notes 8 2 WA470 6H VEAM946100...

Page 389: ...Notes WA470 6H VEAM946100 8 3...

Page 390: ...Notes 8 4 WA470 6H VEAM946100...

Page 391: ...Notes WA470 6H VEAM946100 8 5...

Page 392: ...Notes 8 6 WA470 6H VEAM946100...