Operation

3.4 Transportation

WA470-6H – VEAM946100

3-155

Lifting procedure

CAUTION

When the machine is raised, check that there is no oil leakage

from the hydraulic circuits.

When carrying out the lifting operation, please contact your

KOMATSU distributor.

Lifting work can be carried out only for machines with lifting

marks. Before starting the lifting operation, stop the machine in a

horizontal place and do as follows.

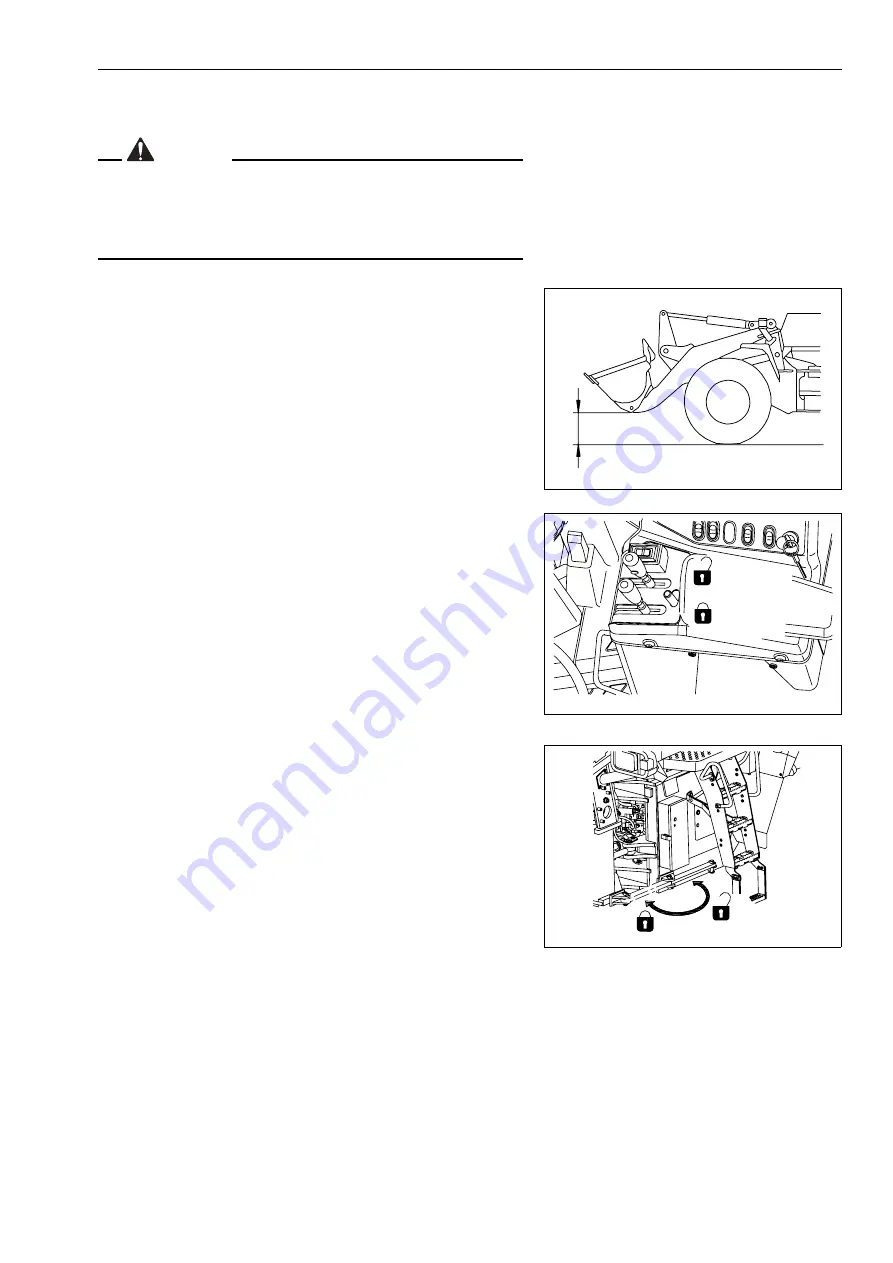

1. Start the engine, make sure that the machine is horizontal,

then set the work equipment to the travel posture.

For details, see "Preparations for moving the machine

(3-114)".

2. Check that the work equipment control lever is at the HOLD

position, then set the safety lock lever to the LOCK position.

3. Stop the engine, check that the area around the operator's

compartment is safe, then lock with the safety bar so that the

front frame and rear frame do not articulate.

4. Use wire ropes and slings that match the weight of the

machine, and wind the wire rope and fix it to the lifting points

as shown in the figure.

NOTE

!

Use protectors, etc. so that the wire ropes will not be broken

at sharp edges or narrow places.

!

Use spreaders and bars having sufficient width so that they

will not touch the machine.

!

For machines equipped with a rear full fender, remove the

rear full fender before carrying out the operation.

5. After setting the wire ropes, lift up the machine and stop at

100 to 200 mm above the ground, and check that the wire

ropes are not slack and the machine is level, then lift up

slowly.

GK032054

270 mm

GK038007

Free

Lock

GK047005

Free

Lock

Summary of Contents for WA470-6 2006

Page 2: ......

Page 3: ...Foreword WA470 6H VEAM946100 1 1 1 Foreword...

Page 22: ...1 5 Contents Foreword 1 20 WA470 6H VEAM946100 7 Index 7 1 7 1 Index 7 2 8 Notes 8 1...

Page 28: ...1 7 CE Conforming equipment Foreword 1 26 WA470 6H VEAM946100...

Page 250: ...3 7 Troubleshooting Operation 3 178 WA470 6H VEAM946100...

Page 340: ...4 9 Service procedure Every 12000 hours service Maintenance 4 90 WA470 6H VEAM946100...

Page 341: ...Technical Data WA470 6H VEAM946100 5 1 5 Technical Data...

Page 343: ...Technical Data 5 1 Technical data WA470 6H VEAM946100 5 3 GK032301 A B H I G C E F D...

Page 348: ...5 4 Limit values for slopes Technical Data 5 8 WA470 6H VEAM946100...

Page 381: ...Index WA470 6H VEAM946100 7 1 7 Index...

Page 387: ...Notes WA470 6H VEAM946100 8 1 8 Notes...

Page 388: ...Notes 8 2 WA470 6H VEAM946100...

Page 389: ...Notes WA470 6H VEAM946100 8 3...

Page 390: ...Notes 8 4 WA470 6H VEAM946100...

Page 391: ...Notes WA470 6H VEAM946100 8 5...

Page 392: ...Notes 8 6 WA470 6H VEAM946100...