Operation

3.7 Troubleshooting

WA470-6H – VEAM946100

3-173

3.7.4

Other trouble

Electrical system

!

( ): Always contact your KOMATSU distributor when deal-

ing with these items.

!

In cases of abnormalities or causes which are not listed

below, please contact your KOMATSU distributor for repairs.

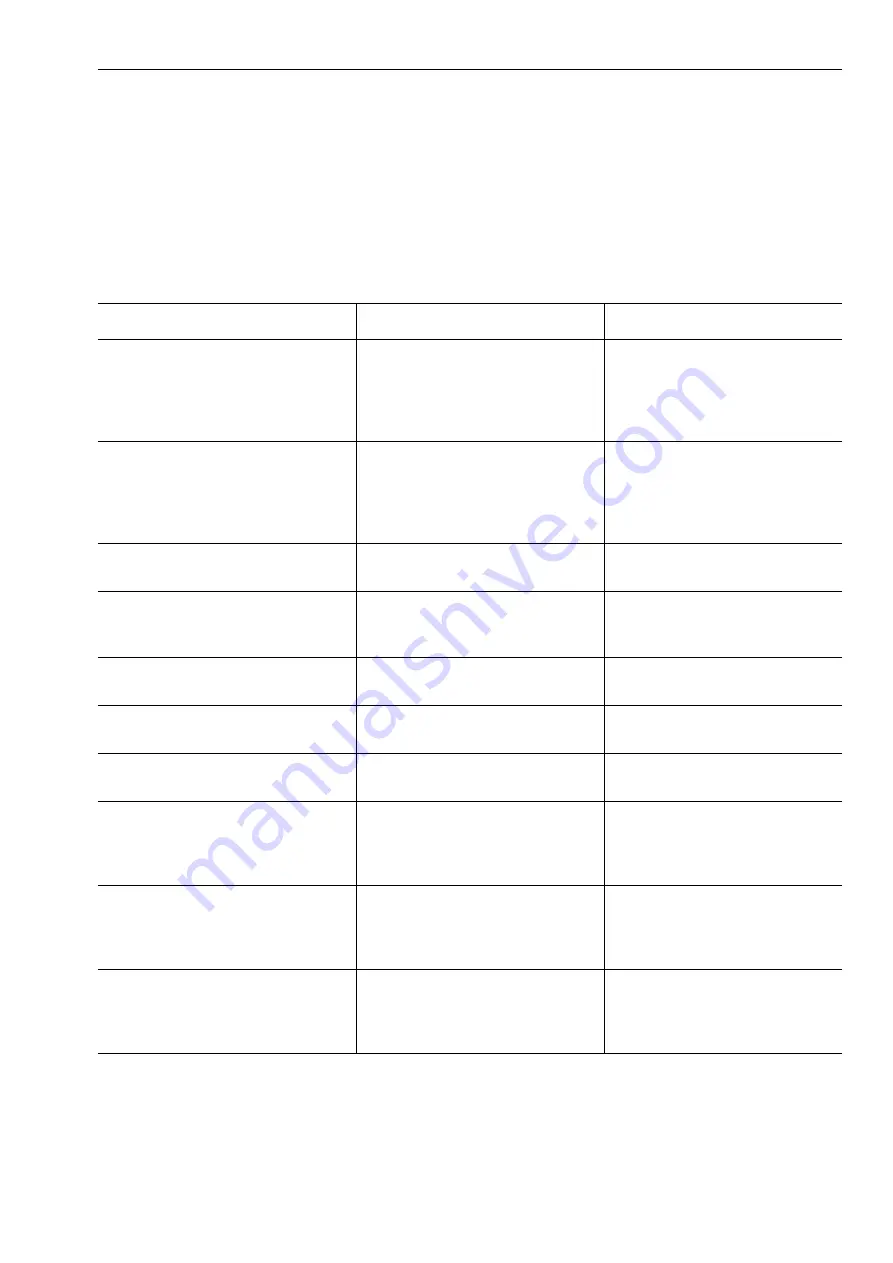

Problem

Main causes

Remedy

Lamp does not glow brightly even

when the engine runs at high speed

Lamp flickers while engine is running

!

Defective wiring

!

Defective adjustment of belt ten-

sion

!

(Check, repair loose terminals,

disconnections)

!

Check, Adjust fan belt tension

For details, see

EVERY 250 HOURS SERVICE

Even when the engine is rotating, the

charge caution pilot lamp does not

go out

!

Defective alternator

!

Defective wiring

!

Defective adjustment of fan belt

tension

!

(Replace)

!

(Check, repair)

!

Check, Adjust fan belt tension

For details, see

EVERY 250 HOURS SERVICE

Abnormal noise is generated from

alternator

!

Defective alternator

!

(Replace)

Starting motor does not turn when

starting switch is turned to START

!

Defective wiring

!

Insufficient battery charge

!

Defective starting motor

!

(Check, repair)

!

Charge

!

(Check, repair)

Pinion of starting motor keeps going

in and out

!

Insufficient battery charge

!

Charge

Starting motor turns engine slug-

gishly

!

Insufficient battery charge

!

Defective starting motor

!

Charge

!

(Replace)

Starting motor disengages before

engine starts

!

Defective wiring

!

Insufficient battery charge

!

(Check, repair)

!

Charge

Preheating pilot lamp does not light

up

!

Defective wiring

!

Defective heater relay, preheat-

ing water temperature sensor

!

Defective preheating pilot lamp

!

(Check, repair)

!

(Replace)

!

(Replace)

Even when engine is stopped,

charge caution pilot lamp does not

light up (starting switch at ON posi-

tion)

!

Defective wiring

!

Defective monitor

!

(Check, repair)

!

(Replace)

Even when engine is stopped,

engine oil pressure caution pilot lamp

does not light up (starting switch at

ON position)

!

Defective pilot lamp

!

Defective pressure caution lamp

!

Defective monitor

!

(Replace)

!

(Replace)

!

(Replace)

Summary of Contents for WA470-6 2006

Page 2: ......

Page 3: ...Foreword WA470 6H VEAM946100 1 1 1 Foreword...

Page 22: ...1 5 Contents Foreword 1 20 WA470 6H VEAM946100 7 Index 7 1 7 1 Index 7 2 8 Notes 8 1...

Page 28: ...1 7 CE Conforming equipment Foreword 1 26 WA470 6H VEAM946100...

Page 250: ...3 7 Troubleshooting Operation 3 178 WA470 6H VEAM946100...

Page 340: ...4 9 Service procedure Every 12000 hours service Maintenance 4 90 WA470 6H VEAM946100...

Page 341: ...Technical Data WA470 6H VEAM946100 5 1 5 Technical Data...

Page 343: ...Technical Data 5 1 Technical data WA470 6H VEAM946100 5 3 GK032301 A B H I G C E F D...

Page 348: ...5 4 Limit values for slopes Technical Data 5 8 WA470 6H VEAM946100...

Page 381: ...Index WA470 6H VEAM946100 7 1 7 Index...

Page 387: ...Notes WA470 6H VEAM946100 8 1 8 Notes...

Page 388: ...Notes 8 2 WA470 6H VEAM946100...

Page 389: ...Notes WA470 6H VEAM946100 8 3...

Page 390: ...Notes 8 4 WA470 6H VEAM946100...

Page 391: ...Notes WA470 6H VEAM946100 8 5...

Page 392: ...Notes 8 6 WA470 6H VEAM946100...