4.6 Periodic replacement of safety critical parts

Torque list

Maintenance

4-26

WA470-6H – VEAM946100

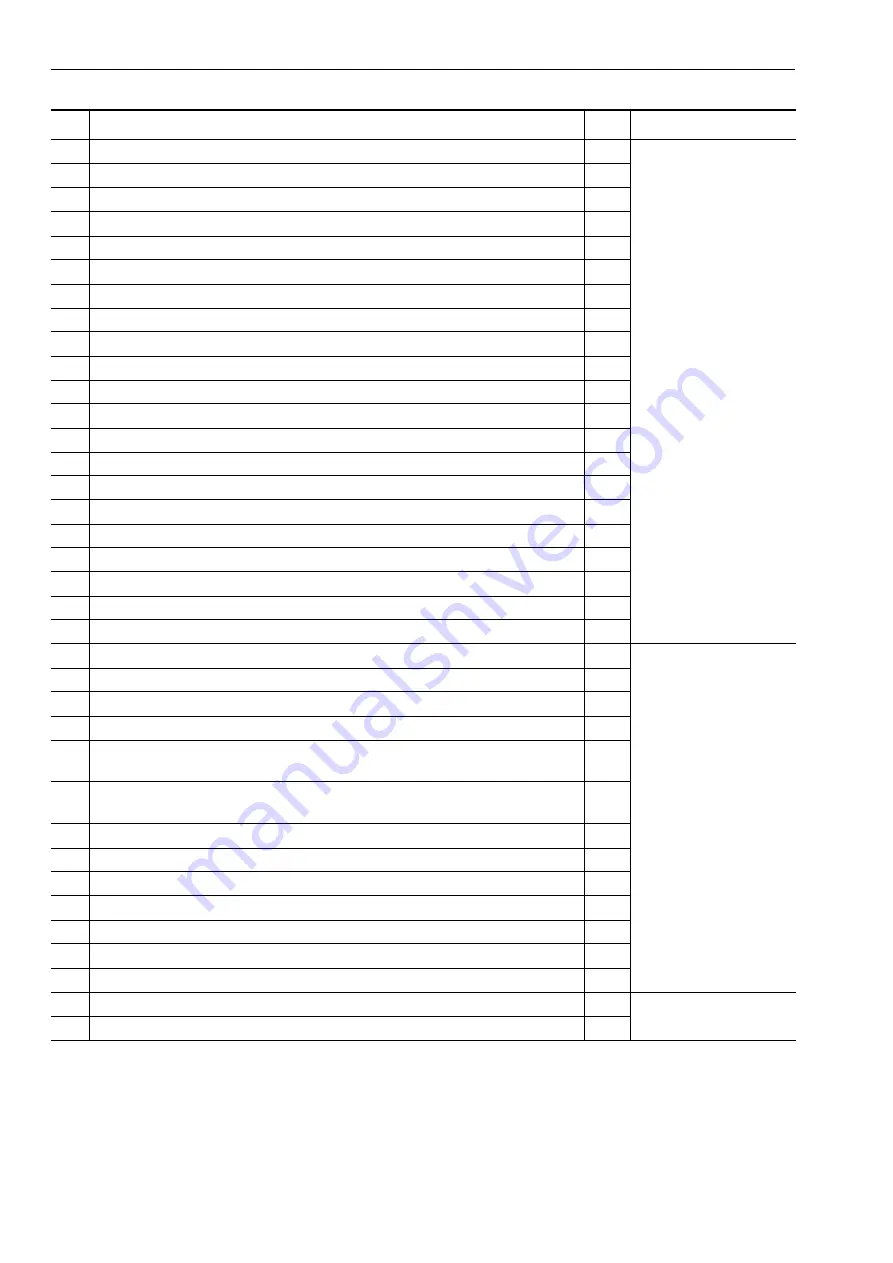

No.

Safety critical parts for periodic replacement

Q'ty Replacement interval

1

Fuel hose (fuel tank - hand pump)

1

Every 2 years or

every 4000 hours

2

Over flow hose (supply pump - fuel tank)

1

3

Spill hose (injector nozzle - fuel tank)

1

4

Steering hose (steering cylinder - tube)

4

5

Steering hose (steering valve - stop valve)

2

6

Steering hose (stop valve drain - centralized drain block)

2

7

Steering hose (stop valve - orbit-roll valve)

2

8

Steering hose (orbit-roll valve - centralized drain block)

1

9

Steering hose (centralized drain block - hydraulic tank)

1

10

Steering hose (steering pump - steering valve)

2

11

Steering hose (emergency steering pump - merge block)

1

12

Steering hose (steering pump - rear frame)

1

13

Steering hose (emergency steering pump - hydraulic tank)

1

14

Steering hose (orbit-roll valve - accumulator charge valve)

2

15

Steering hose (steering valve - hydraulic tank)

2

16

Steering hose (steering valve - centralized drain block)

1

17

Steering hose (steering pump - hydraulic tank)

3

18

Steering hose (steering pump - fan pump)

1

19

Steering oil pressure check line hose (for emergency steering)

3

20

Brake hose (pump - accumulator charge valve)

1

21

Brake hose (brake accumulator - brake valve)

2

22

Brake hose (brake accumulator - brake valve)

2

Every 2 years or

every 4000 hours

23

Brake hose (brake valve drain - hydraulic tank)

1

24

Brake hose (brake valve - front brake)

3

25

Brake hose (brake valve - rear brake)

3

26

Brake hose (brake accumulator - reduction valve for emergency parking

brake cancel)

1

27

Brake hose (reduction valve for emergency parking brake cancel - trans-

mission valve)

1

28

Transmission hose (pump - transmission valve)

1

29

Transmission hose (transmission valve - transmission filter)

1

30

Transmission hose (transmission filter - transmission main valve)

1

31

Transmission hose (transmission - torque converter cooler)

1

32

Transmission hose (torque converter cooler - transmission)

1

33

Accumulator (For PPC)

1

34

Alarm

2

35

Engine high-pressure pipe clamp

1set

Every 8000 hours

36

Fuel splash prevention cap

1set

Summary of Contents for WA470-6 2006

Page 2: ......

Page 3: ...Foreword WA470 6H VEAM946100 1 1 1 Foreword...

Page 22: ...1 5 Contents Foreword 1 20 WA470 6H VEAM946100 7 Index 7 1 7 1 Index 7 2 8 Notes 8 1...

Page 28: ...1 7 CE Conforming equipment Foreword 1 26 WA470 6H VEAM946100...

Page 250: ...3 7 Troubleshooting Operation 3 178 WA470 6H VEAM946100...

Page 340: ...4 9 Service procedure Every 12000 hours service Maintenance 4 90 WA470 6H VEAM946100...

Page 341: ...Technical Data WA470 6H VEAM946100 5 1 5 Technical Data...

Page 343: ...Technical Data 5 1 Technical data WA470 6H VEAM946100 5 3 GK032301 A B H I G C E F D...

Page 348: ...5 4 Limit values for slopes Technical Data 5 8 WA470 6H VEAM946100...

Page 381: ...Index WA470 6H VEAM946100 7 1 7 Index...

Page 387: ...Notes WA470 6H VEAM946100 8 1 8 Notes...

Page 388: ...Notes 8 2 WA470 6H VEAM946100...

Page 389: ...Notes WA470 6H VEAM946100 8 3...

Page 390: ...Notes 8 4 WA470 6H VEAM946100...

Page 391: ...Notes WA470 6H VEAM946100 8 5...

Page 392: ...Notes 8 6 WA470 6H VEAM946100...