4.9 Service procedure

When required

Maintenance

4-38

WA470-6H – VEAM946100

4. Set a container in position to catch the drained antifreeze

mixture, then open drain valve (4) under the left side of the

fuel tank and drain plug (5) at the side of cylinder block, and

drain the coolant.

5. After draining the coolant, close drain valve (4) and drain

plug (5) and fill with city water.

6. When the radiator is full, start the engine, and run it at low

idle.

Keep the engine running at low idle for 10 minutes until the

coolant temperature reaches more than 90°C.

7. Stop the engine, open drain valve (4) and drain plug (5),

drain the water, then tighten them again.

8. After draining the water, clean the cooling system with clean-

ing agent.

For the cleaning method, see the instructions for the clean-

ing agent.

9. Replace the corrosion resistor cartridge, then open 2 valves

(1).

For details of the procedure for replacing the corrosion resis-

tor, see "Replace corrosion resistor cartridge (4-76)".

10. Add coolant mixed with antifreeze until it overflows from the

water filler.

Decide the proportions of antifreeze and water according to

the table for the mixing rate of water and antifreeze.

11. To remove the air in the cooling system, run the engine for 5

minutes at low idling, and for another 5 minutes at high

adling. (When doing this, leave the radiator cap off.)

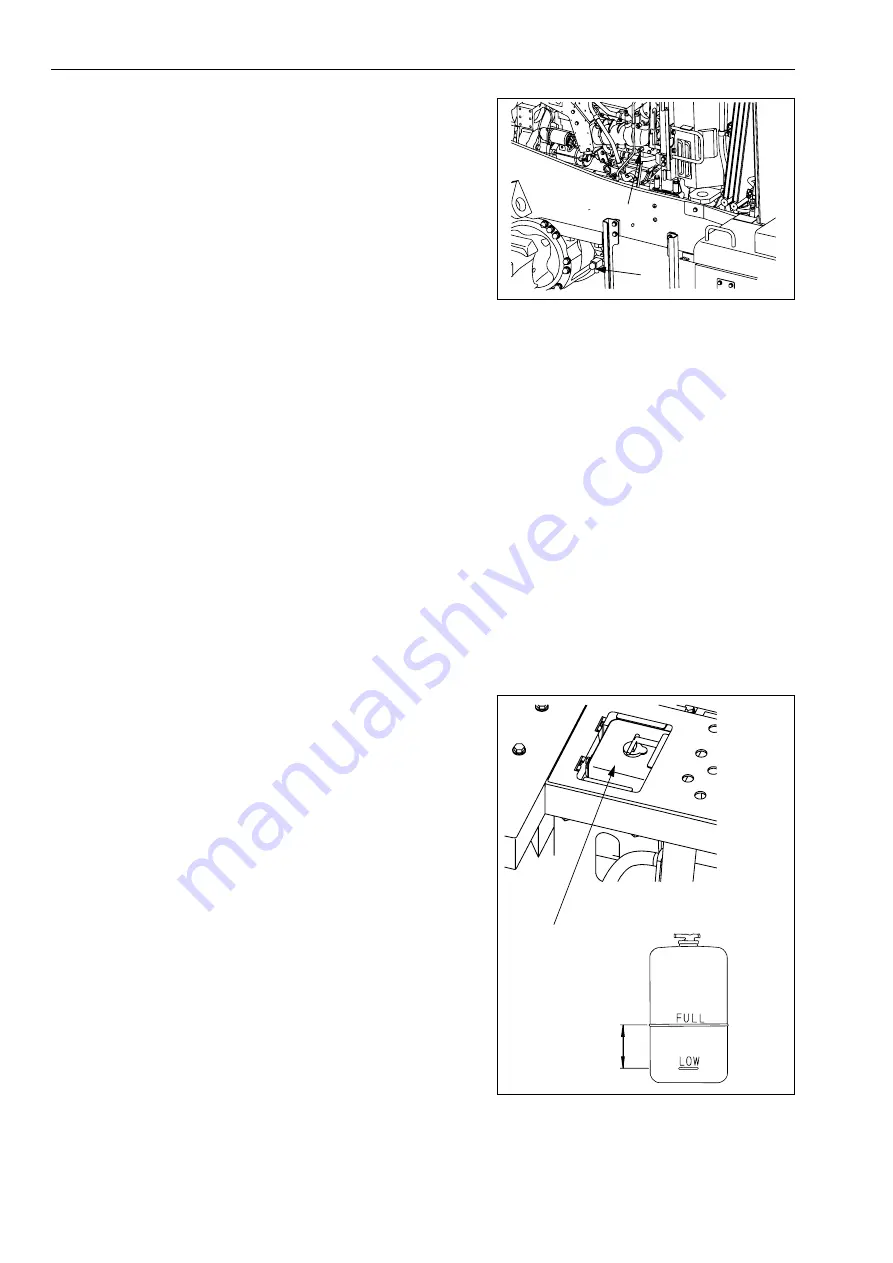

12. Drain the coolant inside sub-tank (6), clean the inside of the

sub-tank, then fill again with coolant to a point midway

between the FULL and LOW marks.

13. Stop the engine, wait for approx. 3 minutes, then add coolant

until the coolant level is near the coolant filler port, and

tighten the cap. Check the coolant level and add coolant if

necessary..

GK047030

4

5

GK032247

GK047031

6

Summary of Contents for WA470-6 2006

Page 2: ......

Page 3: ...Foreword WA470 6H VEAM946100 1 1 1 Foreword...

Page 22: ...1 5 Contents Foreword 1 20 WA470 6H VEAM946100 7 Index 7 1 7 1 Index 7 2 8 Notes 8 1...

Page 28: ...1 7 CE Conforming equipment Foreword 1 26 WA470 6H VEAM946100...

Page 250: ...3 7 Troubleshooting Operation 3 178 WA470 6H VEAM946100...

Page 340: ...4 9 Service procedure Every 12000 hours service Maintenance 4 90 WA470 6H VEAM946100...

Page 341: ...Technical Data WA470 6H VEAM946100 5 1 5 Technical Data...

Page 343: ...Technical Data 5 1 Technical data WA470 6H VEAM946100 5 3 GK032301 A B H I G C E F D...

Page 348: ...5 4 Limit values for slopes Technical Data 5 8 WA470 6H VEAM946100...

Page 381: ...Index WA470 6H VEAM946100 7 1 7 Index...

Page 387: ...Notes WA470 6H VEAM946100 8 1 8 Notes...

Page 388: ...Notes 8 2 WA470 6H VEAM946100...

Page 389: ...Notes WA470 6H VEAM946100 8 3...

Page 390: ...Notes 8 4 WA470 6H VEAM946100...

Page 391: ...Notes WA470 6H VEAM946100 8 5...

Page 392: ...Notes 8 6 WA470 6H VEAM946100...