4.9 Service procedure

Every 250 hours service

Maintenance

4-64

WA470-6H – VEAM946100

Adjusting

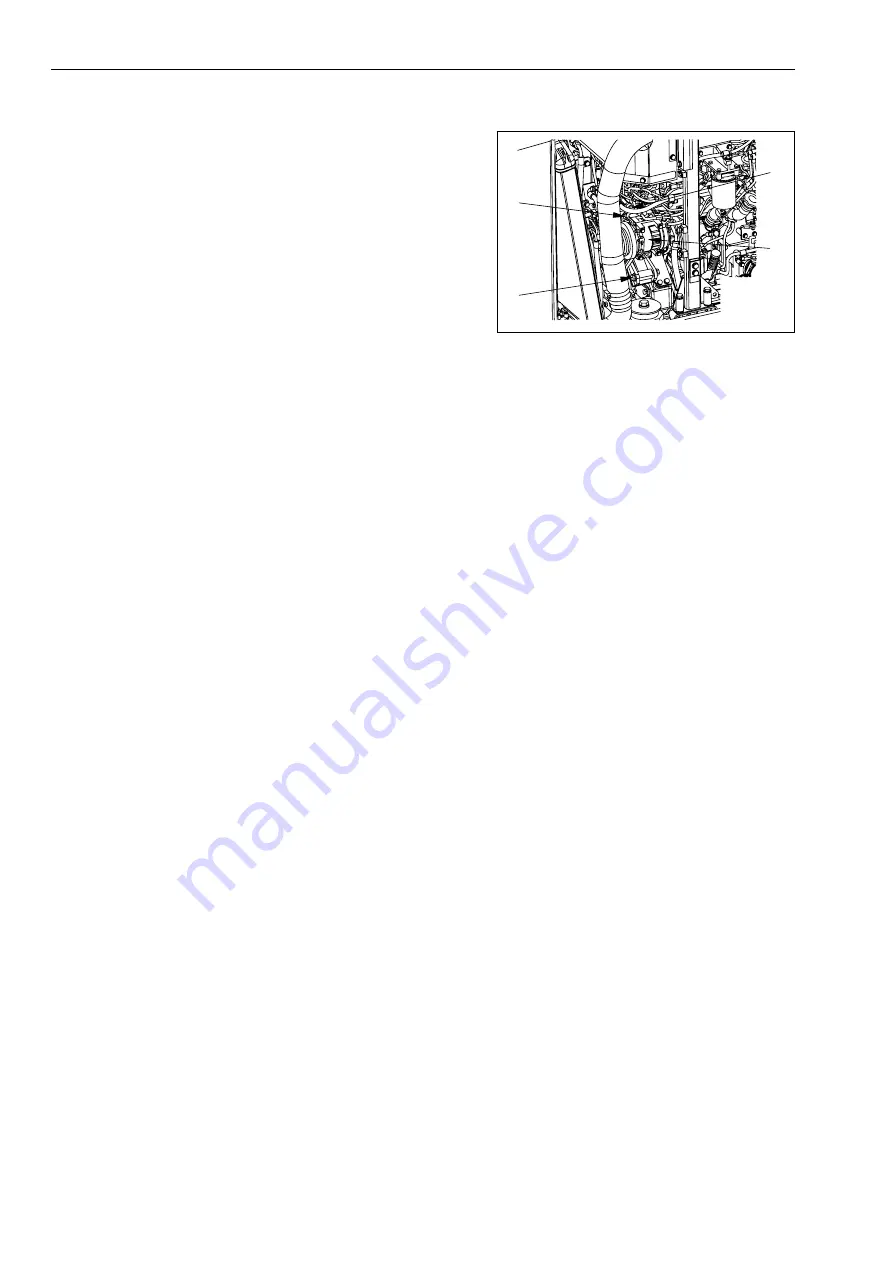

1. Loosen bolts (1) and (2), loosen the locknut of bolt (3), then

loosen bolt (3) and move compressor (4) to adjust.

2. Tighten bolts (1) and (2) and the locknut of bolt (3) to hold

compressor (4) in position.

NOTE

!

Check each pulley for damage, wear of the V-groove, and

wear of the V-belt. In particular, be sure to check that the V-

belt is not touching the bottom of the V-groove.

!

In case any of the following occurs, ask the KOMATSU dis-

tributor in your territory to replace the belts with new ones.

The fan belt has elongated, leaving little allowance for

adjustment.

A cut or crack is found on the belt.

Slipping or creaking sound is heard coming from the belt.

!

When the new V-belt is set, readjust it after one hour of oper-

ation.

GK047044

1

2

3

4

Summary of Contents for WA470-6 2006

Page 2: ......

Page 3: ...Foreword WA470 6H VEAM946100 1 1 1 Foreword...

Page 22: ...1 5 Contents Foreword 1 20 WA470 6H VEAM946100 7 Index 7 1 7 1 Index 7 2 8 Notes 8 1...

Page 28: ...1 7 CE Conforming equipment Foreword 1 26 WA470 6H VEAM946100...

Page 250: ...3 7 Troubleshooting Operation 3 178 WA470 6H VEAM946100...

Page 340: ...4 9 Service procedure Every 12000 hours service Maintenance 4 90 WA470 6H VEAM946100...

Page 341: ...Technical Data WA470 6H VEAM946100 5 1 5 Technical Data...

Page 343: ...Technical Data 5 1 Technical data WA470 6H VEAM946100 5 3 GK032301 A B H I G C E F D...

Page 348: ...5 4 Limit values for slopes Technical Data 5 8 WA470 6H VEAM946100...

Page 381: ...Index WA470 6H VEAM946100 7 1 7 Index...

Page 387: ...Notes WA470 6H VEAM946100 8 1 8 Notes...

Page 388: ...Notes 8 2 WA470 6H VEAM946100...

Page 389: ...Notes WA470 6H VEAM946100 8 3...

Page 390: ...Notes 8 4 WA470 6H VEAM946100...

Page 391: ...Notes WA470 6H VEAM946100 8 5...

Page 392: ...Notes 8 6 WA470 6H VEAM946100...