4.9 Service procedure

Every 2000 hours service

Maintenance

4-78

WA470-6H – VEAM946100

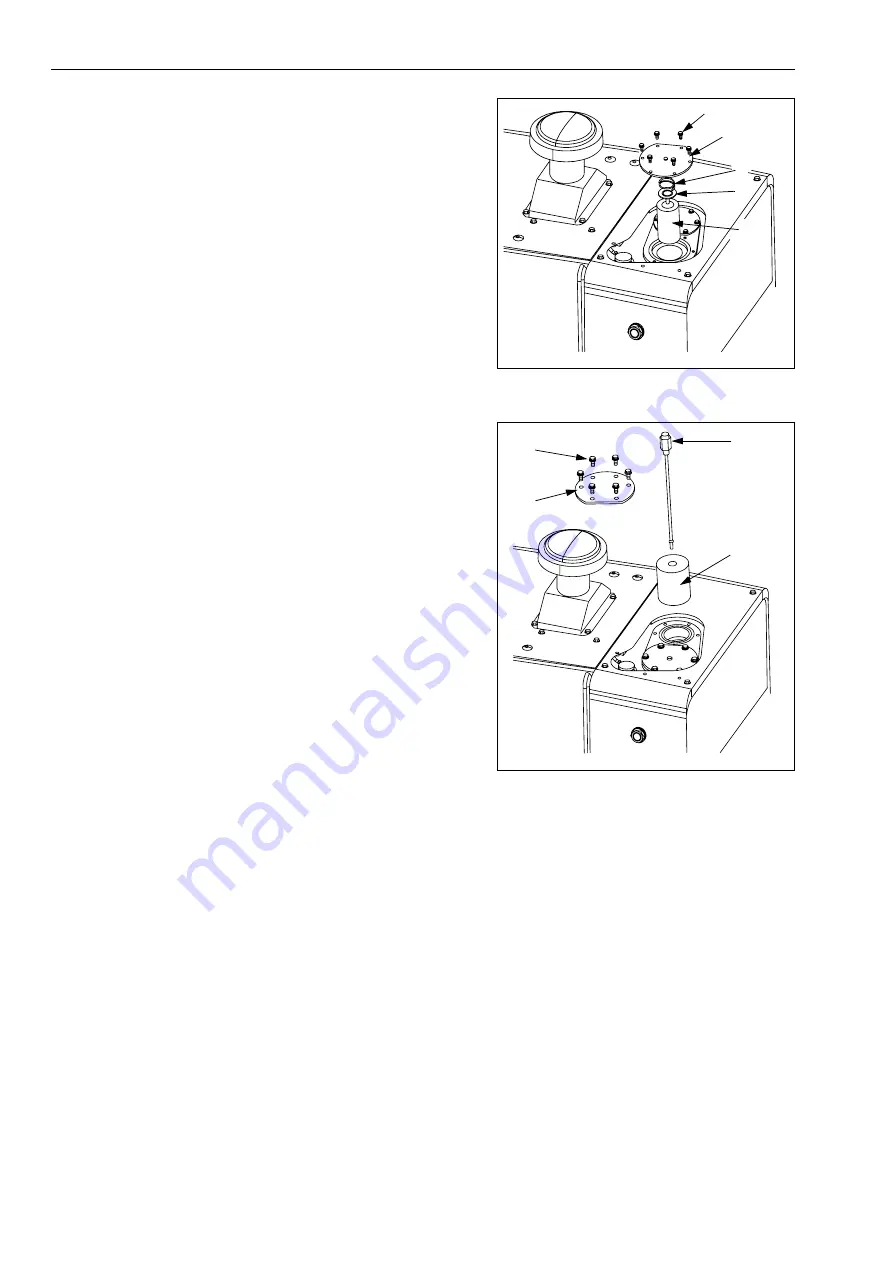

9. Remove mounting bolts (8) of filter cover (7) at the top of the

tank, then remove the cover.

When the cover is removed, the force of spring (9) may

make the cover fly off, so keep the cover pushed down when

removing the bolts.

10. Remove spring (9) and bypass valve (10), then remove ele-

ment (11).

11. Check that there is no foreign material inside the tank, then

clean it.

12. Install new element (11), then set bypass valve (10), spring

(9), and cover (7) to the tank.

If the O-ring of the cover is damaged or deteriorated, replace

it.

13. Remove 6 bolts (13), then remove cover (12).

14. Pull the top of rod (14) from the top and remove strainer

(15).

15. Remove any dirt stuck to strainer (15), then wash it in flush-

ing oil. If strainer (15) is damaged, replace it with a new part.

16. When installing the cover bolts, push down the cover and

tighten the bolts evenly.

17. Add engine oil through oil filler port (F) to the specified level,

then install cap (F).

18. Check that the hydraulic oil is at the specified level.

For details, see "Check oil level in hydraulic tank, add oil

(4-56)".

19. Run the engine at low idling, and extend and retract the

steering, bucket, and lift arm cylinders 4 to 5 times. Be care-

ful not to operate the cylinder to the end of its stroke (stop

approx.100 mm before the end of stroke).

NOTE

If the engine is run immediately at high speed or the cylinder is

operated to the end of its stroke, the air inside the cylinder will

cause damage to the piston packing.

GK047054

8

7

9

10

11

GK047055

12

13

14

15

Summary of Contents for WA470-6 2006

Page 2: ......

Page 3: ...Foreword WA470 6H VEAM946100 1 1 1 Foreword...

Page 22: ...1 5 Contents Foreword 1 20 WA470 6H VEAM946100 7 Index 7 1 7 1 Index 7 2 8 Notes 8 1...

Page 28: ...1 7 CE Conforming equipment Foreword 1 26 WA470 6H VEAM946100...

Page 250: ...3 7 Troubleshooting Operation 3 178 WA470 6H VEAM946100...

Page 340: ...4 9 Service procedure Every 12000 hours service Maintenance 4 90 WA470 6H VEAM946100...

Page 341: ...Technical Data WA470 6H VEAM946100 5 1 5 Technical Data...

Page 343: ...Technical Data 5 1 Technical data WA470 6H VEAM946100 5 3 GK032301 A B H I G C E F D...

Page 348: ...5 4 Limit values for slopes Technical Data 5 8 WA470 6H VEAM946100...

Page 381: ...Index WA470 6H VEAM946100 7 1 7 Index...

Page 387: ...Notes WA470 6H VEAM946100 8 1 8 Notes...

Page 388: ...Notes 8 2 WA470 6H VEAM946100...

Page 389: ...Notes WA470 6H VEAM946100 8 3...

Page 390: ...Notes 8 4 WA470 6H VEAM946100...

Page 391: ...Notes WA470 6H VEAM946100 8 5...

Page 392: ...Notes 8 6 WA470 6H VEAM946100...