2.3 Precautions for operation

Safety

2-26

WA470-6H – VEAM946100

Precautions when operating

!

When using the machine, to prevent the machine from over-

turning due to overloading and to avoid damage to the work

equipment, do not exceed the maximum permitted load or

performance of the machine.

!

If the engine cannot be started again after it has stopped,

immediately operate the work equipment control levers to

lower the work equipment to the ground. (After the engine

stops, the accumulator allows the work equipment to be

operated for a limited time.)

!

Be careful not to approach too close to the edge of cliffs.

When making embankments or landfills, or when dropping

soil over a cliff, dump one pile, then use the next pile of soil

to push the first pile.

!

The load suddenly becomes lighter when the soil is pushed

over a cliff or when the machine reaches the top of a slope.

When this happens, there is danger that the travel speed will

suddenly increase, so be sure to reduce the speed.

!

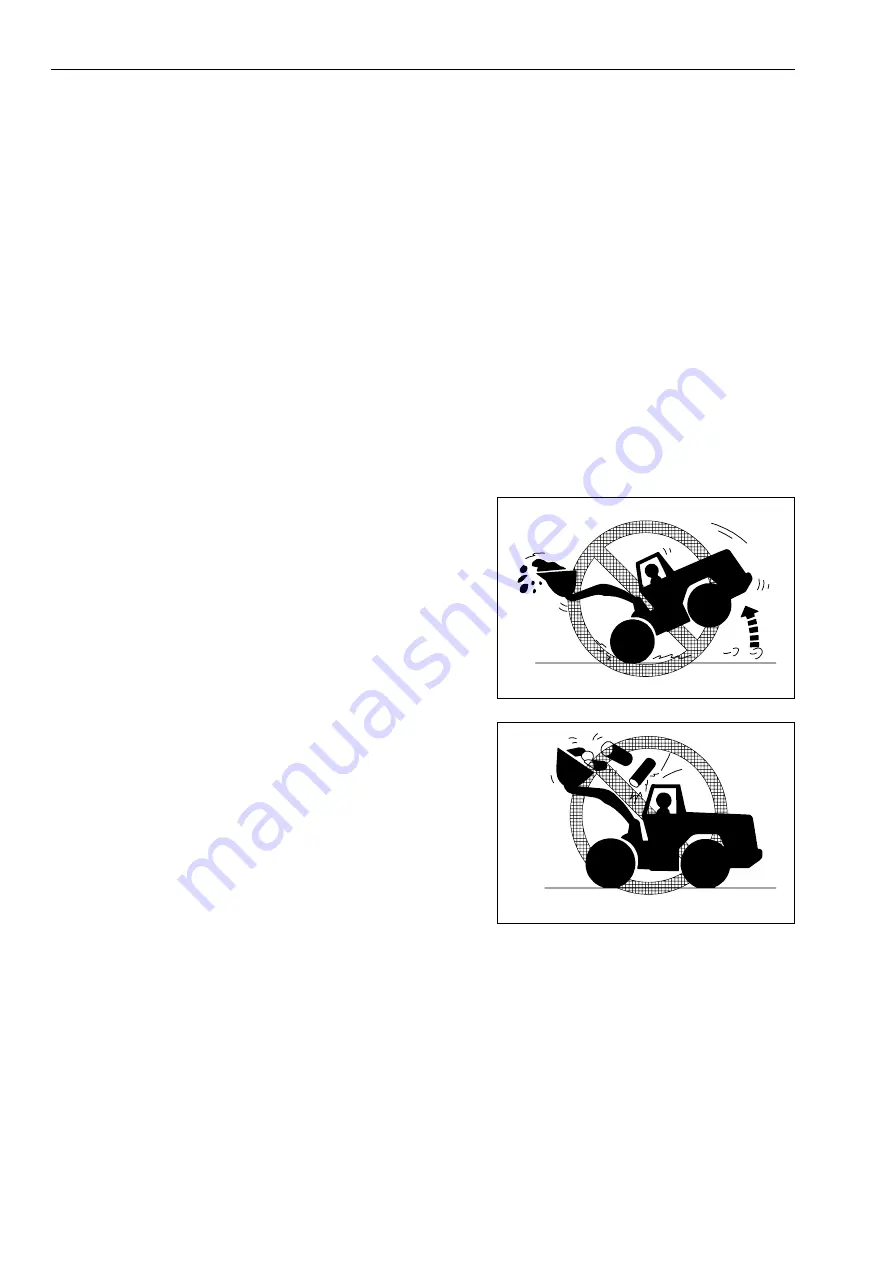

When the bucket is fully loaded, never start, turn, or stop the

machine suddenly. There is danger of the machine turning

over.

!

When handling unstable loads, such as round or cylindrical

objects, or piled sheets, if the work equipment is raised high,

there is danger that the load may fall on top of the operator'

compartment and cause serious injury or damage.

!

When handling unstable loads, be careful not to raise the

work equipment too high or tip the bucket back too much.

!

If the work equipment is suddenly lowered or suddenly

stopped, the reaction may cause the machine to tip over.

Particularly when carrying a load, be sure to operate the

work equipment carefully.

GK032061

GK032062

Summary of Contents for WA470-6 2006

Page 2: ......

Page 3: ...Foreword WA470 6H VEAM946100 1 1 1 Foreword...

Page 22: ...1 5 Contents Foreword 1 20 WA470 6H VEAM946100 7 Index 7 1 7 1 Index 7 2 8 Notes 8 1...

Page 28: ...1 7 CE Conforming equipment Foreword 1 26 WA470 6H VEAM946100...

Page 250: ...3 7 Troubleshooting Operation 3 178 WA470 6H VEAM946100...

Page 340: ...4 9 Service procedure Every 12000 hours service Maintenance 4 90 WA470 6H VEAM946100...

Page 341: ...Technical Data WA470 6H VEAM946100 5 1 5 Technical Data...

Page 343: ...Technical Data 5 1 Technical data WA470 6H VEAM946100 5 3 GK032301 A B H I G C E F D...

Page 348: ...5 4 Limit values for slopes Technical Data 5 8 WA470 6H VEAM946100...

Page 381: ...Index WA470 6H VEAM946100 7 1 7 Index...

Page 387: ...Notes WA470 6H VEAM946100 8 1 8 Notes...

Page 388: ...Notes 8 2 WA470 6H VEAM946100...

Page 389: ...Notes WA470 6H VEAM946100 8 3...

Page 390: ...Notes 8 4 WA470 6H VEAM946100...

Page 391: ...Notes WA470 6H VEAM946100 8 5...

Page 392: ...Notes 8 6 WA470 6H VEAM946100...