Operation

3.2 Explanation of components

WA470-6H – VEAM946100

3-21

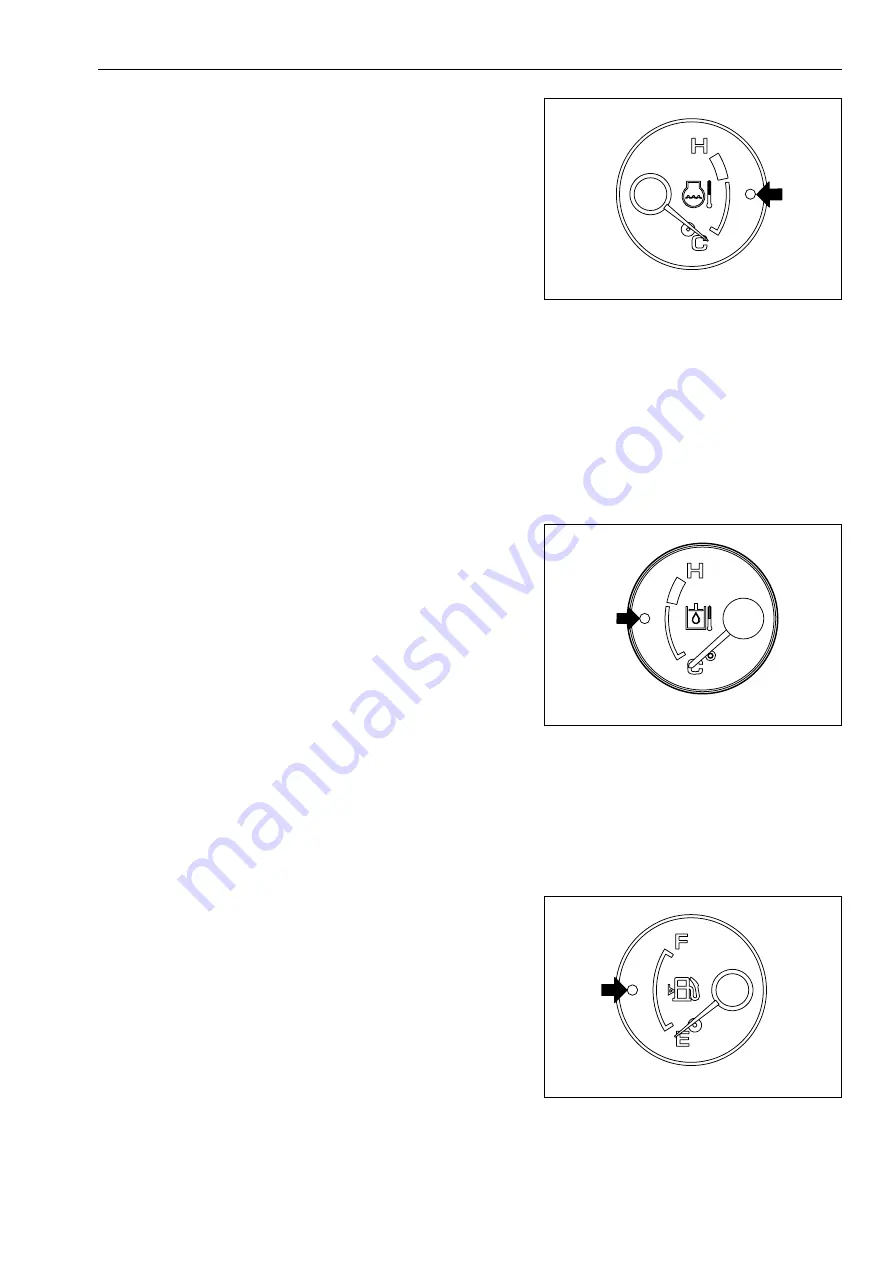

3. Engine coolant temperature caution lamp

This lamp (3) lights up to warn the operator that the engine cool-

ant water temperature has risen.

During checks before starting (when the starting switch is turned

to the ON position but the engine is not started), this monitor

does not light up.

During operation (engine running)

If the engine coolant temperature rises, only the engine coolant

water temperature caution lamp will light up.

If the coolant temperature rises further, the central warning lamp

will light up and the alarm buzzer will sound intermittently.

At the same time as the central warning lamp lights up, the top

line of the character display displays “E02“ and the bottom line

displays “BRAKE OVERHEAT“, so stop the machine and run the

engine under no load at a mid-range speed until the lamp goes

out.

4. Hydraulic oil temperature caution lamp

This lamp (4) lights up to warn the operator that the hydraulic oil

temperature has risen.

During checks before starting (when the starting switch is turned

to the ON position but the engine is not started), this monitor

does not light up.

During operation (engine running)

If the hydraulic oil temperature rises, the hydraulic oil tempera-

ture caution lamp, the central warning lamp will light up, and the

alarm buzzer will sound intermittently.

At the same time, “E02“ is displayed on the top line of the char-

acter display and “HYD OVERHEAT“ is displayed on the bottom

line. Stop the machine and run the engine under no load at a

mid-range speed until the lamp goes out.

5. Fuel level caution lamp

This lamp (5) lights up if the amount of fuel remaining in the fuel

tank goes below 35 liters (9,25 US gal).

If it lights up, check and add fuel as soon as possible.

For details, see "Check fuel level, add fuel (3-97)".

REMARK

Even if the caution lamp lights up, action code “E02“ is not dis-

played on the character display.

GK032100

GK043105

GK032101

Summary of Contents for WA470-6 2006

Page 2: ......

Page 3: ...Foreword WA470 6H VEAM946100 1 1 1 Foreword...

Page 22: ...1 5 Contents Foreword 1 20 WA470 6H VEAM946100 7 Index 7 1 7 1 Index 7 2 8 Notes 8 1...

Page 28: ...1 7 CE Conforming equipment Foreword 1 26 WA470 6H VEAM946100...

Page 250: ...3 7 Troubleshooting Operation 3 178 WA470 6H VEAM946100...

Page 340: ...4 9 Service procedure Every 12000 hours service Maintenance 4 90 WA470 6H VEAM946100...

Page 341: ...Technical Data WA470 6H VEAM946100 5 1 5 Technical Data...

Page 343: ...Technical Data 5 1 Technical data WA470 6H VEAM946100 5 3 GK032301 A B H I G C E F D...

Page 348: ...5 4 Limit values for slopes Technical Data 5 8 WA470 6H VEAM946100...

Page 381: ...Index WA470 6H VEAM946100 7 1 7 Index...

Page 387: ...Notes WA470 6H VEAM946100 8 1 8 Notes...

Page 388: ...Notes 8 2 WA470 6H VEAM946100...

Page 389: ...Notes WA470 6H VEAM946100 8 3...

Page 390: ...Notes 8 4 WA470 6H VEAM946100...

Page 391: ...Notes WA470 6H VEAM946100 8 5...

Page 392: ...Notes 8 6 WA470 6H VEAM946100...