Attachments, Options

6.4 Joystick steering system

WA470-6H – VEAM946100

6-17

6.4.3

Operation method of joystick steering system

WARNING

!

It is dangerous to turn the machine suddenly at high speed,

or to turn on steep hills. Do not operate the steering in such

conditions.

!

When turning, the articulation stops at the position where the

steering wheel is turned to, but if the joystick is held in the

tilted position, the body will articulate fully.

!

The feeling when operating the steering with the joystick is

different from when operating with the steering wheel, so be

extremely careful until you have become used to operating

the joystick.

Check the adjustment and operation before starting the engine.

For details, see "Check before starting engine, adjust (3-88)".

1. Before starting the engine, check the operation of the joy-

stick lever steering, check that the transmission directional

lever is at N, and that the surrounding area is safe.

REMARK

Under the following conditions, a warning may be given when

the engine is started.

!

If the FNR switch on the joystick is at F or R, the joystick pilot

lamp flashes, the central warning lamp lights up, and the

alarm buzzer sounds.

!

At the same time, “E00 J/S SW NEUTRAL“ is displayed on

the character display. In this condition, the engine will not

start, so set the FNR switch to N.

!

If the joystick is not at the N position, the joystick pilot lamp

flashes, the central warning lamp lights up, and the alarm

buzzer sounds.

!

At the same time, “E00 J/S LEVER POSI“ is displayed on

the character display. In this condition, the engine will not

start, so set the joystick to the N position.

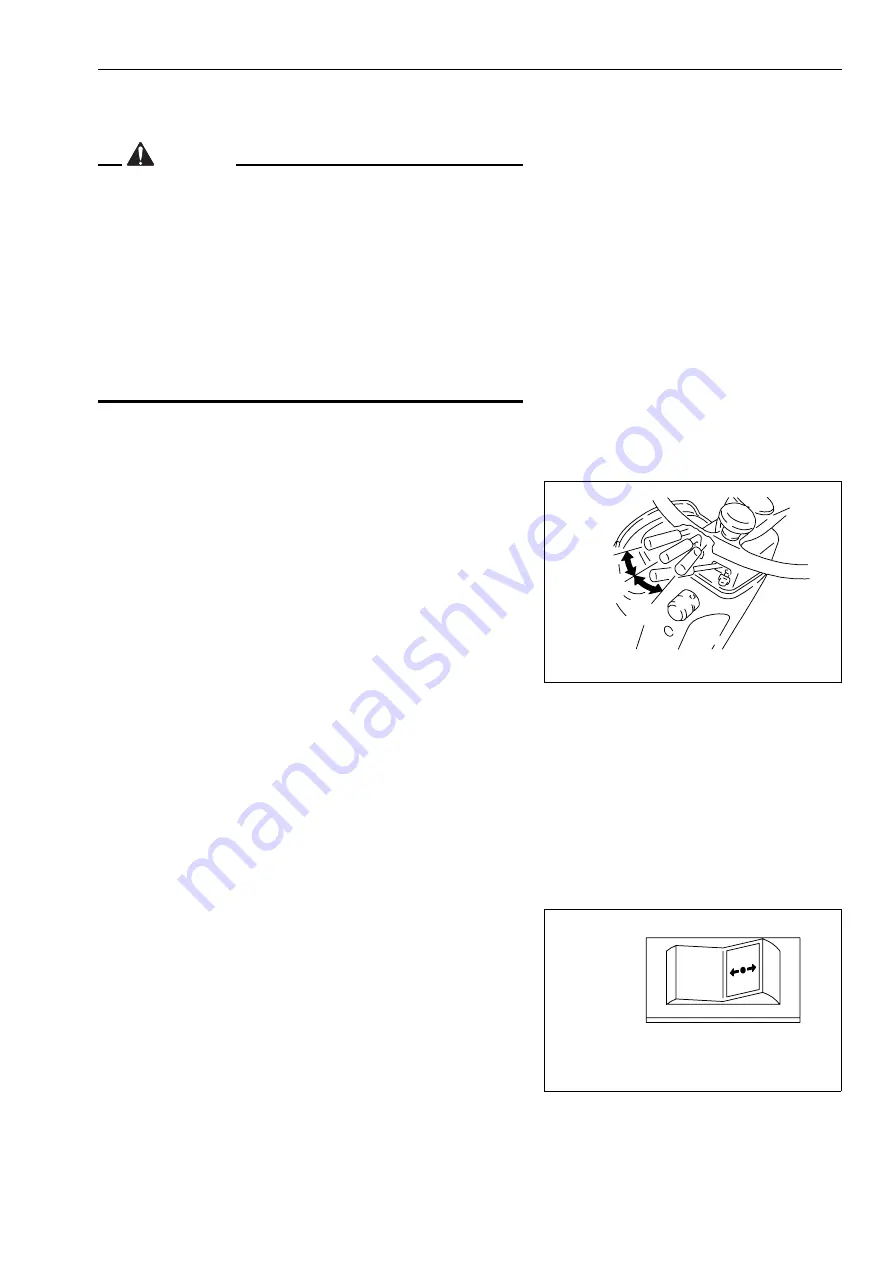

2. Press the (a) part of the joystick ON/OFF switch to turn it

ON.

GK043144

F

N

R

GK043186

a

b

Summary of Contents for WA470-6 2006

Page 2: ......

Page 3: ...Foreword WA470 6H VEAM946100 1 1 1 Foreword...

Page 22: ...1 5 Contents Foreword 1 20 WA470 6H VEAM946100 7 Index 7 1 7 1 Index 7 2 8 Notes 8 1...

Page 28: ...1 7 CE Conforming equipment Foreword 1 26 WA470 6H VEAM946100...

Page 250: ...3 7 Troubleshooting Operation 3 178 WA470 6H VEAM946100...

Page 340: ...4 9 Service procedure Every 12000 hours service Maintenance 4 90 WA470 6H VEAM946100...

Page 341: ...Technical Data WA470 6H VEAM946100 5 1 5 Technical Data...

Page 343: ...Technical Data 5 1 Technical data WA470 6H VEAM946100 5 3 GK032301 A B H I G C E F D...

Page 348: ...5 4 Limit values for slopes Technical Data 5 8 WA470 6H VEAM946100...

Page 381: ...Index WA470 6H VEAM946100 7 1 7 Index...

Page 387: ...Notes WA470 6H VEAM946100 8 1 8 Notes...

Page 388: ...Notes 8 2 WA470 6H VEAM946100...

Page 389: ...Notes WA470 6H VEAM946100 8 3...

Page 390: ...Notes 8 4 WA470 6H VEAM946100...

Page 391: ...Notes WA470 6H VEAM946100 8 5...

Page 392: ...Notes 8 6 WA470 6H VEAM946100...