GENERAL PRECAUTIONS COMMON TO OPERATION

AND MAINTENANCE

Mistakes in operation, inspection, or maintenance may result in serious personal injury or death. Before per-

forming operation, inspection, or maintenance, always read this manual and the safety labels on the machine

carefully and obey the warnings.

PRECAUTIONS BEFORE STARTING OPERATION

ENSURE SAFE OPERATION

• Only trained and authorized personnel can operate and maintain the machine.

• Follow all safety, precautions, and instructions in this manual when operating or performing inspection or

maintenance on the machine.

• If you are not feeling well, or if you are under the influence of alcohol or medication, your ability to safely

operate or repair your machine may be severely impaired, putting yourself and everyone else on your job

site in danger.

• When working with another operator or with the person on the worksite traffic duty, discuss the content of

the operation beforehand and use the determined signals when performing the operation.

UNDERSTAND THE MACHINE

Before operating the machine, read this manual thoroughly. If there is any place in this manual that you do not

understand, ask the person in charge of safety for explanation.

PREPARATIONS FOR SAFE OPERATION

PRECAUTIONS FOR SAFETY-RELATED EQUIPMENT

• Be sure that all guards, covers, cameras, and mirrors are in their proper position. Repair them immediately

if they are damaged.

• Understand the using method of the safety related devices and use them properly.

• Never remove any safety related devices. Always keep them in good operating condition.

INSPECT MACHINE

Check the machine before starting operations. If any abnormality is found, do not operate the machine until re-

pairs of the problem location have been completed.

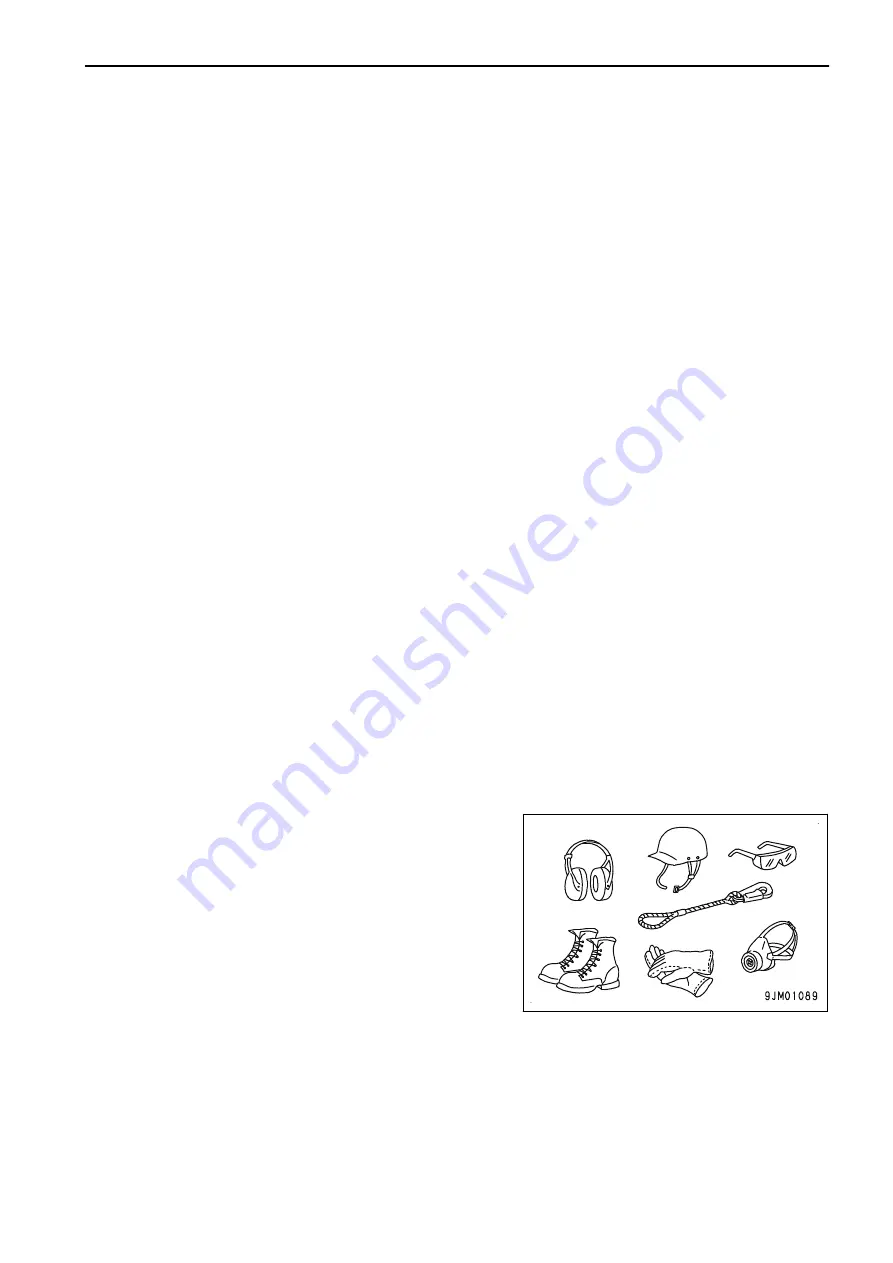

WEAR WELL-FITTING CLOTHES AND PROTECTIVE EQUIPMENT

• Do not wear loose clothes or any accessories. If any of

these catch the control levers or protruding parts, it may

cause the machine to move unexpectedly, it is extremely

dangerous.

• Always wear a hard hat and safety shoes. Wear protective

eyeglasses, mask, gloves, ear plugs, and safety belt as

appropriate for the work function.

• Long hair hanging out from the hard hat is dangerous that

it may get caught up in the machine. Tie the hair up and be

careful not to be caught.

• Check that all personal protective items function properly

before using them.

KEEP MACHINE CLEAN

• If you get on or off the machine or perform inspection and maintenance on the machine with mud or oil, you

may slip and fall, and it is dangerous. Wipe off any mud or oil from the machine. Always keep the machine

clean.

SAFETY

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTE-

NANCE

2-15