DO NOT DROP THINGS INSIDE MACHINE ..................................................................................... 4-2

PRECAUTIONS FOR KDPF .............................................................................................................. 4-3

PRECAUTIONS FOR SCR ASSEMBLY ............................................................................................ 4-3

DUSTY JOBSITES............................................................................................................................. 4-3

AVOID MIXING OIL............................................................................................................................ 4-3

LOCK INSPECTION COVERS .......................................................................................................... 4-3

BLEED AIR FROM HYDRAULIC CIRCUIT ........................................................................................ 4-3

PRECAUTIONS WHEN INSTALLING HYDRAULIC HOSES ............................................................. 4-3

CHECKS AFTER INSPECTION AND MAINTENANCE...................................................................... 4-3

FUEL AND LUBRICANTS TO MATCH THE AMBIENT TEMPERATURE........................................... 4-4

CLOSE ENGINE SIDE COVER SECURELY...................................................................................... 4-4

OUTLINE OF MAINTENANCE.................................................................................................................. 4-5

HANDLE OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC .................................................. 4-5

HANDLE ELECTRICAL COMPONENTS ........................................................................................... 4-9

STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS.............................................................. 4-10

MAINTENANCE SCHEDULE.................................................................................................................. 4-12

MAINTENANCE SCHEDULE TABLE............................................................................................... 4-12

MAINTENANCE INTERVAL WHEN DIESEL FUEL MIXED WITH BIO-FUEL IS USED ................... 4-13

MAINTENANCE PROCEDURE .............................................................................................................. 4-15

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS) ............................ 4-15

WHEN REQUIRED .......................................................................................................................... 4-15

CHECKS BEFORE STARTING........................................................................................................ 4-40

EVERY 50 HOURS MAINTENANCE ............................................................................................... 4-41

EVERY 100 HOURS MAINTENANCE ............................................................................................. 4-41

EVERY 250 HOURS MAINTENANCE ............................................................................................. 4-43

EVERY 500 HOURS MAINTENANCE ............................................................................................. 4-48

EVERY 1000 HOURS MAINTENANCE ........................................................................................... 4-51

EVERY 2000 HOURS MAINTENANCE ........................................................................................... 4-56

EVERY 4000 HOURS MAINTENANCE ........................................................................................... 4-71

EVERY 4500 HOURS MAINTENANCE ........................................................................................... 4-76

EVERY 8000 HOURS MAINTENANCE ........................................................................................... 4-76

EVERY 9000 HOURS MAINTENANCE ........................................................................................... 4-77

SPECIFICATIONS ........................................................................................................................................... 5-1

SPECIFICATIONS .................................................................................................................................... 5-2

SPECIFICATIONS: WA480-8............................................................................................................. 5-2

ATTACHMENTS AND OPTIONS ..................................................................................................................... 6-1

BUCKET AND TIRE SELECTION............................................................................................................. 6-2

HANDLE MULTIFUNCTION MONO-LEVER ............................................................................................. 6-3

EXPLANATION OF EQUIPMENT ON MULTIFUNCTION MONO-LEVER.......................................... 6-3

MULTIFUNCTION MONO-LEVER ..................................................................................................... 6-3

KICKDOWN SWITCH ........................................................................................................................ 6-4

HOLD SWITCH.................................................................................................................................. 6-5

DIRECTIONAL SELECTER SWITCH ON MULTIFUNCTION MONO-LEVER.................................... 6-5

PCS(PROPORTIONAL CONTROL SWITCH).................................................................................... 6-6

LCD UNIT .......................................................................................................................................... 6-7

OIL FLOW CONTROL MODE PILOT LAMP (FIXED OIL FLOW MODE) ........................................... 6-7

OIL FLOW CONTROL MODE PILOT LAMP (PROPORTIONAL OIL FLOW MODE) ......................... 6-8

DETENT OPERATION PILOT LAMP ................................................................................................. 6-8

ATTACHMENT OIL FLOW LEVEL ..................................................................................................... 6-8

METHOD FOR SETTING PCS .......................................................................................................... 6-9

SEAT HEATER AND SEAT VENTILATION ..............................................................................................6-11

METHOD FOR HEATING SEAT .......................................................................................................6-11

METHOD FOR USING SEAT VENTILATION................................................................................... 6-12

HANDLE SEAT BELT.............................................................................................................................. 6-13

METHOD FOR FASTENING AND UNFASTENING SEAT BELT...................................................... 6-13

REPLACEMENT PARTS.................................................................................................................................. 7-1

PERIODIC REPLACEMENT OF DEFINED LIFE PARTS.......................................................................... 7-2

DEFINED LIFE PARTS LIST.............................................................................................................. 7-2

FOREWORD

TABLE OF CONTENTS

1-23

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

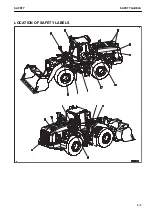

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......