STARTING MACHINE AFTER LONG-TERM STORAGE

NOTICE

If the machine has been stored without performing the monthly rust-prevention operation, consult your

Komatsu distributor before using it.

When using the machine after long-term storage, perform the following items before using it.

• Wipe off the grease from the hydraulic cylinder rods.

• Add oil and grease at all lubrication points.

• When the machine is stored for a long period, moisture in the air will mix with the oil. Check the oil before

and after starting the engine. If there is water in the oil, change all the oil.

• Check for rust on engine pulley and abnormality on belt.

If the surface of pulley where contacting with the belt is covered with too much rust, remove them with wire

brush.

• Insert the battery disconnect switch key and turn it to ON position.

For the operation method, see “BATTERY DISCONNECT SWITCH (3-123)”.

• If the machine is stored for a long period with the battery disconnect switch OFF or the battery terminal dis-

connected, the time setting of the clock may be lost. In this case, set them again. For detail, see “CLOCK

ADJUSTMENT (3-81)”.

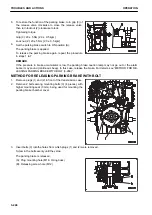

• If the machine has been stored for more than 2 months, perform the following procedure.

• Before starting the engine, replace DEF filter and fill up DEF tank.

• Start the engine and check correctly.

If SCR system has any abnormality, warning is displayed on the monitor screen and the audible alert

sounds. If SCR system has any abnormality, stop the engine, and then start it again.

If SCR system still has abnormality after the engine is restarted, contact your Komatsu distributor.

• If DEF is kept in DEF tank for more than 1 year, ask your Komatsu distributor for replacement.

Dispose of drained DEF according to the local regulations and rules.

Aged DEF may have smell of ammonia. Replace DEF in a well-ventilated place and take care not to

inhale its vapor.

PRECAUTIONS FOR LONG-TERM STORAGE

OPERATION

3-242

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......