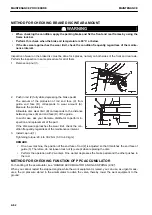

When installing the DEF tank filler (3), take care about the

direction.

10. Install the bolts (2) (4 pieces).

Tightening torque: 9.5 to 10.5 Nm {0.97 to 1.07 kgm}

11. Align the claw (6) of cap (1) with groove (7) of the filler port

and close the cap securely by turning it clockwise by 90 °.

EVERY 4000 HOURS MAINTENANCE

Maintenance for every 50, 100, 250, 500, 1000 and 2000 hours service should be performed at the same time.

REPLACE DEFINED LIFE PARTS

Material quality of these parts can change as time passes and they are likely to wear out or deteriorate.

Replace them every 2 years or every 4000 hours, whichever comes sooner.

MAINTENANCE

MAINTENANCE PROCEDURE

4-71

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

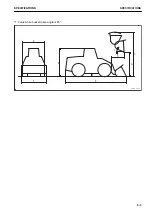

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......