METHOD FOR CHECKING EXHAUST PIPE FIRE PREVENTION COVER

k

k

WARNING

Immediately after the engine is stopped, all the parts are still very hot, and may cause burn injury. Wait

for the temperature to go down, and then start the work.

NOTICE

Exhaust pipe fire prevention cover (1) may suffer material deterioration or damage depending on the

conditions of use and the operating environment of the machine.

1.

Open the engine side cover on the left side of the ma-

chine.

2.

Check exhaust pipe fire prevention cover (1).

If any part is deteriorated or damaged, ask your Komatsu distributor for replacement.

EVERY 4500 HOURS MAINTENANCE

Maintenance for every 50, 100, 250 and 500 hours service should be performed at the same time.

METHOD FOR CLEANING KDPF

Contact your Komatsu distributor for cleaning of the KDPF.

METHOD FOR CLEANING DEF TANK

Ask your Komatsu distributor for cleaning of the DEF tank.

METHOD FOR CLEANING FUEL DOSER

For cleaning the fuel doser, ask your Komatsu distributor.

METHOD FOR CHECKING FOR MISSING FUEL SPRAY PREVENTION CAP ON

FUEL DOSER PIPING, HARDENING OF RUBBER

Ask your Komatsu distributor to have the fuel spray prevention cap on fuel doser checked.

EVERY 8000 HOURS MAINTENANCE

Maintenance for every 50, 100, 250, 500, 1000, 2000 and 4000 hours service should be performed at the same

time.

METHOD FOR REPLACING ENGINE HIGH-PRESSURE PIPING CLAMP

Special techniques and tools are required for this work.

Ask your Komatsu distributor for replacement of the engine high-pressure piping.

METHOD FOR REPLACING FUEL SPRAY PREVENTION CAP

Ask your Komatsu distributor for replacement of the fuel spray prevention caps.

METHOD FOR OVERHAULING STARTING MOTOR AND ALTERNATOR

Special techniques and tools are required for this work.

Ask your Komatsu distributor to have the starting motor and alternator overhauled.

MAINTENANCE PROCEDURE

MAINTENANCE

4-76

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

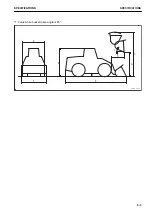

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......