• Prohibit other personnel to get on the machine.

• If there are any persons in the area around the machine,

there is danger that they may be hit or caught by the ma-

chine, and this may lead to serious personal injury or

death. Always observe the following before traveling.

• Always operate the machine only when seated on the

operator's seat.

• Before starting to move, check again that there is no

people or obstacle in the surrounding area.

• Before moving, sound the horn to warn people in the

surrounding area.

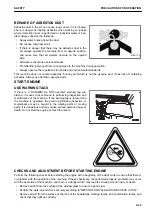

• Check that the backup alarm (alarm buzzer when machine travels in reverse) works properly.

• If there is an area in the rear of the machine which cannot be seen, allocate a conductor.

Always be sure to perform the above precautions even when the machine is equipped with mirrors and cam-

eras.

When traveling downhill through inertia, set the direction of the directional lever or directional selector switch (if

equipped) to the position that matches the machine traveling direction. If the directional lever or directional se-

lector switch (if equipped) is set to the direction opposite to that of the machine travel, engine stall can result

and it is very dangerous.

PRECAUTIONS WHEN TRAVELING

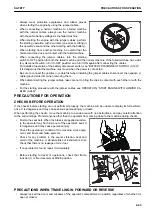

Serious personal injury or death can result from tipping over of the traveling machine or its accidental contact.

Always observe the following.

• Never turn the key in the starting switch to OFF position when the machine is traveling. If the engine stops

when the machine is traveling, the steering wheel becomes heavy to operate, and this will cause a wrong

operation of the steering wheel and may lead to serious personal injury or death. If the engine stops, de-

press the brake pedal immediately to stop the machine.

• When driving the machine or performing operations, always keep a safe distance from people, structures,

or other machines to avoid coming into contact with them.

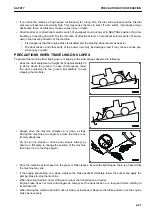

• When traveling on a level ground, keep the work equip-

ment (A) approximately 27 cm above the ground. If that

height is not maintained between the work equipment and

the ground, the work equipment may get stuck in the

ground and the machine may tip over.

When you are forced to operate the work equipment con-

trol lever, do it after stopping the travel once.

• Try to avoid traveling over obstacles. If the machine has to

travel over an obstacle, keep the work equipment close to

the ground and travel at low speed. The machine tips over

easily to the right or left. Do not drive it over obstacles

which make the machine tilt largely to the right or left.

• When driving the machine on the rough ground, drive it at low speed and do not operate the steering sud-

denly. There is a danger that the machine may tip over. The work equipment may hit the ground, and the

machine may lose its balance, or it may damage the machine or structures in the area.

• When using the machine, to prevent serious personal injury or death caused by the work equipment or by

the machine tipping over due to overloading, do not use the machine beyond the permitted performance of

the machine such as the maximum permitted load for the structure of the machine.

• When passing over bridges or structures, check first that the structure is strong enough to support the

weight of the machine.

• When operating in tunnels, under bridges, under electric wires, or other places where the height is limited,

operate slowly and be extremely careful not to let the machine body or work equipment hit anything.

PRECAUTIONS FOR OPERATION

SAFETY

2-26

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......