STANDARD TIGHTENING TORQUE FOR BOLTS AND

NUTS

Tightening torque list

k

k

CAUTION

If nuts, bolts, or other parts are not tightened to the specified torque, it will cause looseness or damage

to the tightened parts, and this will cause failure of the machine or problems with operation. Always be

careful when tightening parts.

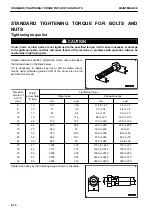

Unless otherwise specified, tighten the metric nuts and bolts to

the torque shown in the table below.

If it is necessary to replace any nut or bolt, Komatsu recom-

mends using Komatsu genuine part of the same size as the

part that is removed.

Thread di-

ameter of

bolt “a”

(mm)

Width

across flats

“b” (mm)

Tightening torque

Target value

Allowable range

Nm

kgm

Nm

kgm

6

8

10

12

14

10

13

17

19

22

13.3

31

67

111

172

1.35

3.2

6.8

11.3

17.5

11.8 to 14.7

27 to 34

59 to 74

98 to 123

153 to 190

1.2 to 1.5

2.8 to 3.5

6.0 to 7.5

10.0 to 12.5

15.5 to 19.5

16

18

20

22

24

24

27

30

32

36

260

360

510

688

883

26.5

37

52.3

70.3

90

235 to 285

320 to 400

455 to 565

610 to 765

785 to 980

23.5 to 29.5

33 to 41

46.5 to 58

62.5 to 78

80 to 100

27

30

33

36

39

41

46

50

55

60

1295

1715

2205

2745

3260

133

175

225

280

333

1150 to 1440

1520 to 1910

1960 to 2450

2450 to 3040

2890 to 3630

118 to 147

155 to 195

200 to 250

250 to 310

295 to 370

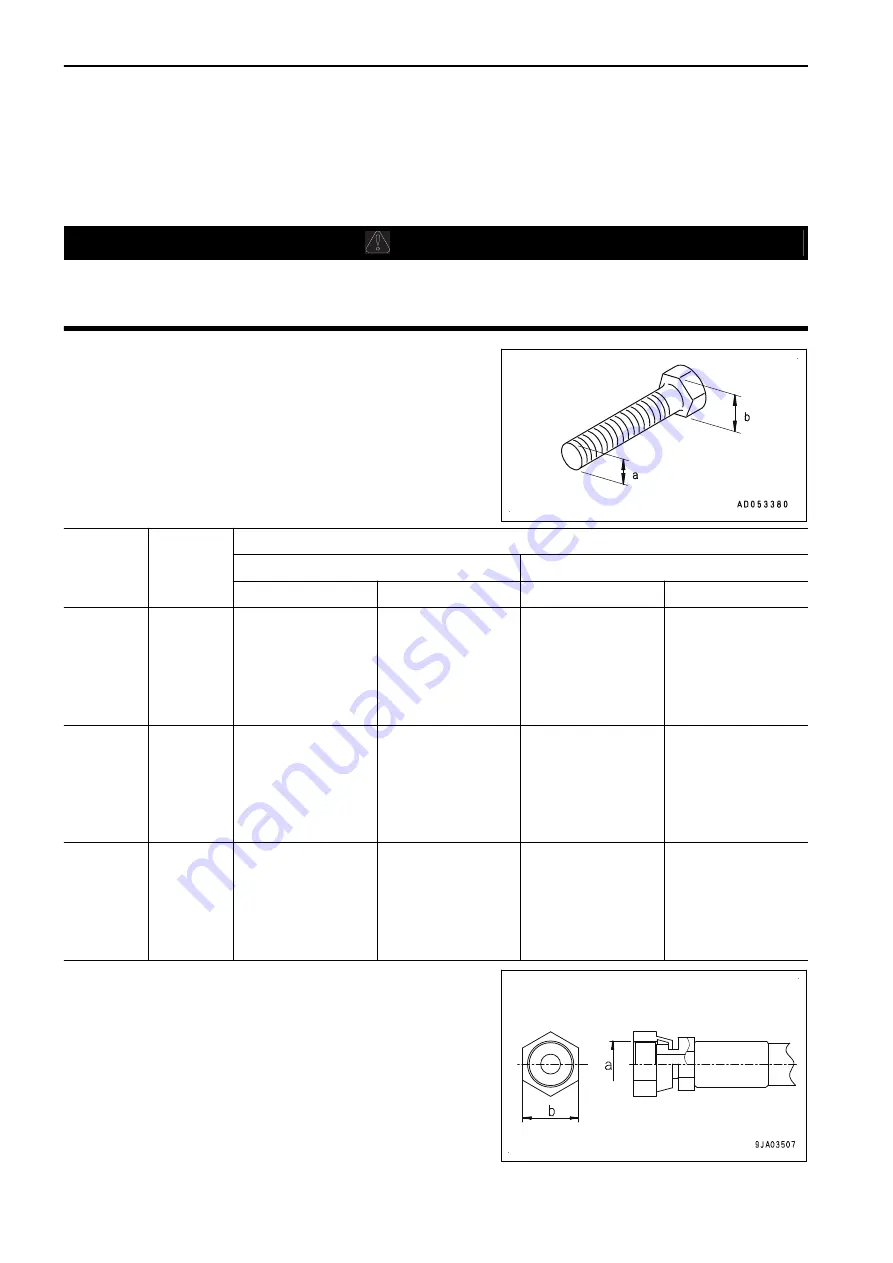

Tighten the hoses by the following torque shown in the table.

STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS

MAINTENANCE

4-10

Summary of Contents for WA480-8

Page 2: ......

Page 19: ...Distributor name Address Phone Fax Service personnel FOREWORD PRODUCT INFORMATION 1 17...

Page 29: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3...

Page 159: ...SWITCHES 1 ECSS switch 2 Front working lamp switch OPERATION EXPLANATION OF COMPONENTS 3 91...

Page 302: ...Securing position Fixing angle A 61 B 53 C 33 D 38 TRANSPORTATION OPERATION 3 234...

Page 324: ......

Page 397: ...Viewed from the rear side of the machine MAINTENANCE MAINTENANCE PROCEDURE 4 73...

Page 402: ......

Page 403: ...SPECIFICATIONS 5 1...

Page 406: ......

Page 422: ......

Page 423: ...REPLACEMENT PARTS 7 1...

Page 439: ......