Operation

3.2 Descriptions of the individual elements

WA70-7 – VENAM02003

3-45

3.2.13

Air conditioner

(Option)

NOTICE

Only use the air conditioner when the engine is running. Let the

air conditioner run for about 10 minutes every month to prevent

the compressor shaft seal from drying out.

Do not let the air conditioner run for an extended period of time

at low engine speeds to prevent the battery from discharging.

Keep the cab doors and windows closed when the engine is run-

ning.

If the machine was exposed to strong sunlight for an extended

period of time, it is recommended to air the cab thoroughly when

starting the machine and turning on the air conditioner.

Turning on the air conditioner

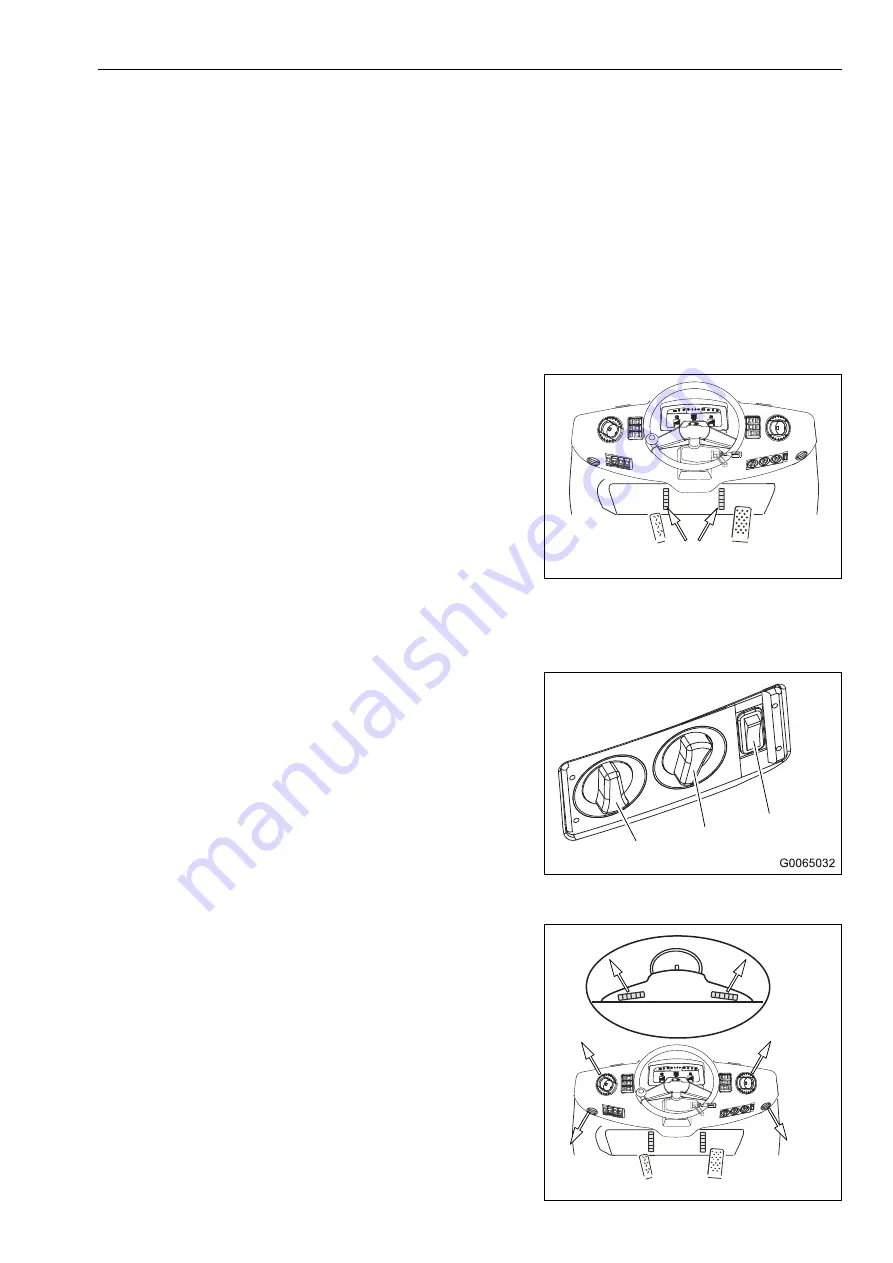

1. Open all air intake nozzles (b), if equipped.

NOTICE

If the air intake nozzles are closed (b), the cooling capacity

decreases.

2. Turn the fan switch (1) to position '4'.

3. Turn the temperature control switch (2) to 'cold'.

4. Activate the air conditioner switch (3).

The air conditioner is now on. This setting achieves the

greatest cooling effect, especially if the engine is running at

high speed.

5. Turn the fan switch (1) back one position when the desired

temperature has been reached.

6. Use the temperature dial for further adjustment.

7. The air is distributed by means of air outlet nozzles (a).

You can open and close all air outlet nozzles (a) individu-

ally.

The airflow may be directed with the diffuser discs.

The air outlet nozzles (a) can be directed at the wind-

screen and at the side windows.

G0070290A

b

a

=

Air outlet nozzles

b

=

Air intake nozzles

1

2

3

G0070280A

a

a

a

a

a

a

Summary of Contents for WA70-7

Page 2: ......

Page 3: ...Foreword WA70 7 VENAM02003 1 1 1 Foreword...

Page 23: ...Foreword 1 5 Table of contents WA70 7 VENAM02003 1 21 Blank for technical reason...

Page 28: ...1 7 Equipment Foreword 1 26 WA70 7 VENAM02003...

Page 75: ...Operation WA70 7 VENAM02003 3 1 3 Operation...

Page 114: ...3 2 Descriptions of the individual elements Operation 3 40 WA70 7 VENAM02003 Fuse allocation...

Page 185: ...Troubleshooting WA70 7 VENAM02003 4 1 4 Troubleshooting...

Page 203: ...Maintenance WA70 7 VENAM02003 5 1 5 Maintenance...

Page 277: ...Technical data WA70 7 VENAM02003 6 1 6 Technical data...

Page 283: ...Special equipment attachments WA70 7 VENAM02003 7 1 7 Special equipment attachments...

Page 291: ...Index WA70 7 VENAM02003 8 1 8 Index...

Page 296: ...8 1 Index Index 8 6 WA70 7 VENAM02003...

Page 297: ...Notes WA70 7 VENAM02003 9 1 9 Notes...

Page 298: ...Notes 9 2 WA70 7 VENAM02003...

Page 299: ...Notes WA70 7 VENAM02003 9 3...

Page 300: ...Notes 9 4 WA70 7 VENAM02003...

Page 301: ...Notes WA70 7 VENAM02003 9 5...

Page 302: ...Notes 9 6 WA70 7 VENAM02003...