5.8 Maintenance procedure

Maintenance every 50 service hours

Maintenance

5-42

WA70-7 – VENAM02003

Lubrication – work equipment

DANGER

Performing maintenance on a machine that is not properly

parked and secured may cause severe accidents!

Park the machine on solid, level ground. Secure the

machine before beginning maintenance work.

1. For maintenance work, park the machine as described in

chapter 5.1 “Maintenance guide” (5-2).

2. Clean the indicated grease nipples.

3. Use a grease pump to press a sufficient amount of grease

into the grease nipples.

4. Remove any excess old grease that is pushed out at the

bearings.

WA70-7

(1)

Tilt rod

(2 points)

(2)

Multi-purpose bucket

(6 points)

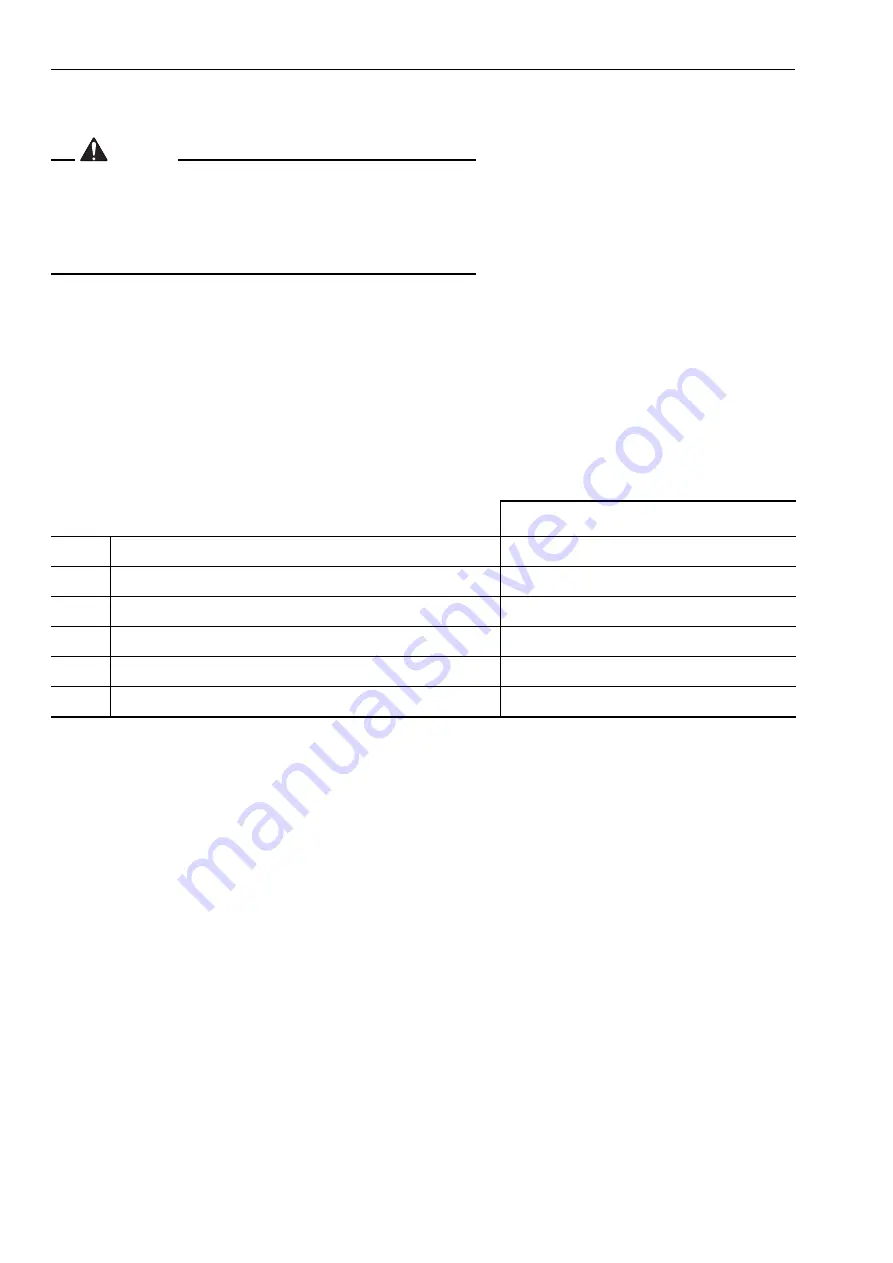

(3)

Upper and lower lift cylinders

(2 points)

(4)

Tilt arm

(2 points)

(5)

Left and right boom

(4 points)

(6)

Tilt cylinder

(2 points)

Summary of Contents for WA70-7

Page 2: ......

Page 3: ...Foreword WA70 7 VENAM02003 1 1 1 Foreword...

Page 23: ...Foreword 1 5 Table of contents WA70 7 VENAM02003 1 21 Blank for technical reason...

Page 28: ...1 7 Equipment Foreword 1 26 WA70 7 VENAM02003...

Page 75: ...Operation WA70 7 VENAM02003 3 1 3 Operation...

Page 114: ...3 2 Descriptions of the individual elements Operation 3 40 WA70 7 VENAM02003 Fuse allocation...

Page 185: ...Troubleshooting WA70 7 VENAM02003 4 1 4 Troubleshooting...

Page 203: ...Maintenance WA70 7 VENAM02003 5 1 5 Maintenance...

Page 277: ...Technical data WA70 7 VENAM02003 6 1 6 Technical data...

Page 283: ...Special equipment attachments WA70 7 VENAM02003 7 1 7 Special equipment attachments...

Page 291: ...Index WA70 7 VENAM02003 8 1 8 Index...

Page 296: ...8 1 Index Index 8 6 WA70 7 VENAM02003...

Page 297: ...Notes WA70 7 VENAM02003 9 1 9 Notes...

Page 298: ...Notes 9 2 WA70 7 VENAM02003...

Page 299: ...Notes WA70 7 VENAM02003 9 3...

Page 300: ...Notes 9 4 WA70 7 VENAM02003...

Page 301: ...Notes WA70 7 VENAM02003 9 5...

Page 302: ...Notes 9 6 WA70 7 VENAM02003...