5.8 Maintenance procedure

Maintenance

Maintenance every 500 service hours

WA70-7 – VENAM02003

5-55

Bleeding the fuel system

DANGER

The fuel in the injection system is pressurised! Ejected fuel may

puncture the skin and cause blood poisoning. Wear safety gog-

gles and rubber gloves when working on the injection pump. In

the event of being hit by a high-pressure fuel jet, immediately

consult a doctor.

For maintenance work, park and secure the machine as

described in chapter 5.1 “Maintenance guide” (5-2).

WA70-7

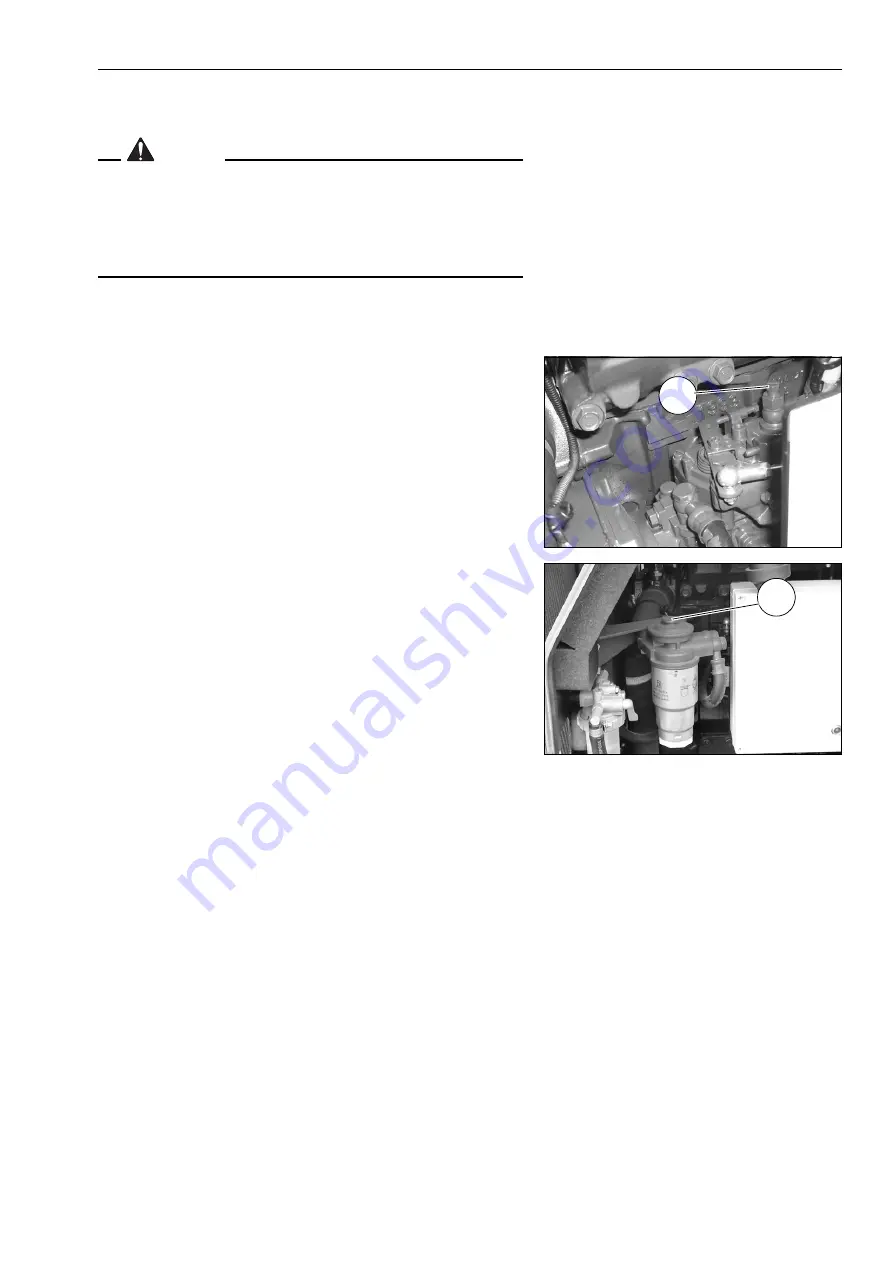

1. Loosen the bleed screw (1) on the injection pump.

2. Move the pump button (2) on the fuel filter until there are no

more bubbles in the fuel flowing from the bleed screw.

3. Retighten the bleed screw (1).

1

2

Summary of Contents for WA70-7

Page 2: ......

Page 3: ...Foreword WA70 7 VENAM02003 1 1 1 Foreword...

Page 23: ...Foreword 1 5 Table of contents WA70 7 VENAM02003 1 21 Blank for technical reason...

Page 28: ...1 7 Equipment Foreword 1 26 WA70 7 VENAM02003...

Page 75: ...Operation WA70 7 VENAM02003 3 1 3 Operation...

Page 114: ...3 2 Descriptions of the individual elements Operation 3 40 WA70 7 VENAM02003 Fuse allocation...

Page 185: ...Troubleshooting WA70 7 VENAM02003 4 1 4 Troubleshooting...

Page 203: ...Maintenance WA70 7 VENAM02003 5 1 5 Maintenance...

Page 277: ...Technical data WA70 7 VENAM02003 6 1 6 Technical data...

Page 283: ...Special equipment attachments WA70 7 VENAM02003 7 1 7 Special equipment attachments...

Page 291: ...Index WA70 7 VENAM02003 8 1 8 Index...

Page 296: ...8 1 Index Index 8 6 WA70 7 VENAM02003...

Page 297: ...Notes WA70 7 VENAM02003 9 1 9 Notes...

Page 298: ...Notes 9 2 WA70 7 VENAM02003...

Page 299: ...Notes WA70 7 VENAM02003 9 3...

Page 300: ...Notes 9 4 WA70 7 VENAM02003...

Page 301: ...Notes WA70 7 VENAM02003 9 5...

Page 302: ...Notes 9 6 WA70 7 VENAM02003...