5.8 Maintenance procedure

Maintenance every 1500 service hours

Maintenance

5-64

WA70-7 – VENAM02003

5.8.11

Maintenance every 1500 service hours

Also perform all maintenance tasks scheduled to be carried out

every 10, 50, 100, 250, 500, and 1000 service hours.

Front and rear axle – change oil

WARNING

Repeated skin contact with used hydraulic oil can cause skin

damage and other bodily harm!

Wear rubber gloves when changing the filter. Carefully wash

off hydraulic oil that has come into contact with the skin.

DANGER

Performing maintenance on a machine that is not properly

parked and secured may cause severe accidents!

Park the machine on solid, level ground. Secure the

machine before beginning maintenance work.

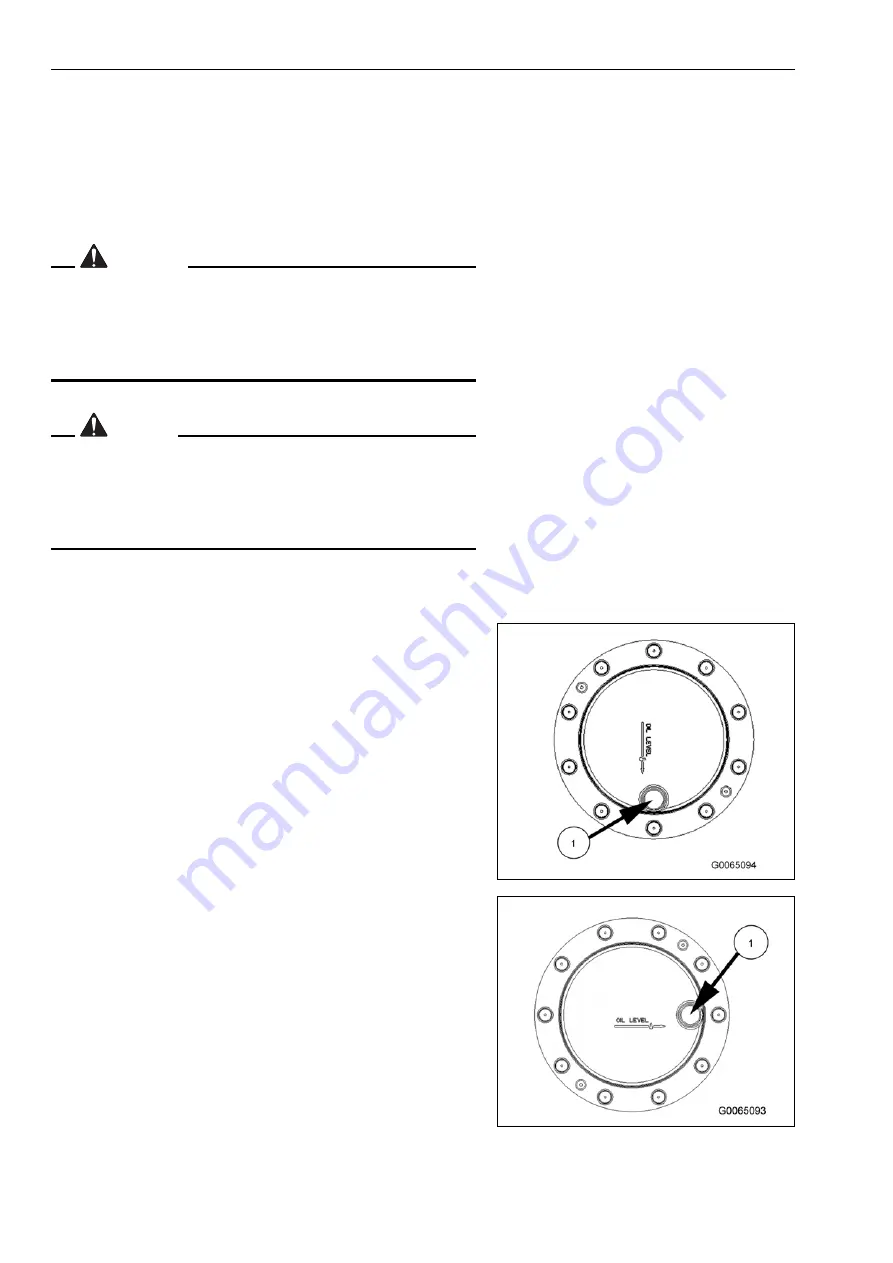

Epicyclic gearing

1. Start the engine, raise the work equipment, and move the

machine until the screw plug (1) of the epicyclic gearing on

the wheel to be checked is at the lowest point. Switch off the

engine, lower the work equipment, and apply the parking

brake.

2. Place a drain tray underneath the screw plug (1).

3. Remove the screw plug (1) and drain the oil.

4. Move the machine until the plug bore (1) of the epicyclic

gearing is horizontal.

5. Fill the epicyclic gearing with oil until the oil level reaches the

lower edge of the plug bore (1).

F o r m o r e i n f o r m a t i o n o n r e c o m m e n d e d o i l s , s e e

chapter 5.4 “Fuel, lubricants, and coolants; quantities”

(5-18).

6. Clean the screw plug and install an intact seal.

7. Insert the screw plug and tighten firmly.

Torque (1) = 60 Nm

8. Change the oil on the other wheels at the front and rear axle

as described in items 1. to 7.

Summary of Contents for WA70-7

Page 2: ......

Page 3: ...Foreword WA70 7 VENAM02003 1 1 1 Foreword...

Page 23: ...Foreword 1 5 Table of contents WA70 7 VENAM02003 1 21 Blank for technical reason...

Page 28: ...1 7 Equipment Foreword 1 26 WA70 7 VENAM02003...

Page 75: ...Operation WA70 7 VENAM02003 3 1 3 Operation...

Page 114: ...3 2 Descriptions of the individual elements Operation 3 40 WA70 7 VENAM02003 Fuse allocation...

Page 185: ...Troubleshooting WA70 7 VENAM02003 4 1 4 Troubleshooting...

Page 203: ...Maintenance WA70 7 VENAM02003 5 1 5 Maintenance...

Page 277: ...Technical data WA70 7 VENAM02003 6 1 6 Technical data...

Page 283: ...Special equipment attachments WA70 7 VENAM02003 7 1 7 Special equipment attachments...

Page 291: ...Index WA70 7 VENAM02003 8 1 8 Index...

Page 296: ...8 1 Index Index 8 6 WA70 7 VENAM02003...

Page 297: ...Notes WA70 7 VENAM02003 9 1 9 Notes...

Page 298: ...Notes 9 2 WA70 7 VENAM02003...

Page 299: ...Notes WA70 7 VENAM02003 9 3...

Page 300: ...Notes 9 4 WA70 7 VENAM02003...

Page 301: ...Notes WA70 7 VENAM02003 9 5...

Page 302: ...Notes 9 6 WA70 7 VENAM02003...