5.8 Maintenance procedure

Maintenance

Maintenance after the first 50 service hours

WA70-7 – VENAM02003

5-37

5.8.3

Maintenance after the first 50 service hours

Carry out the following maintenance only after the first 50 ser-

vice hours.

Hydraulic system – change filter insert

For details see “Hydraulic system – change venting filters”

(5-62).

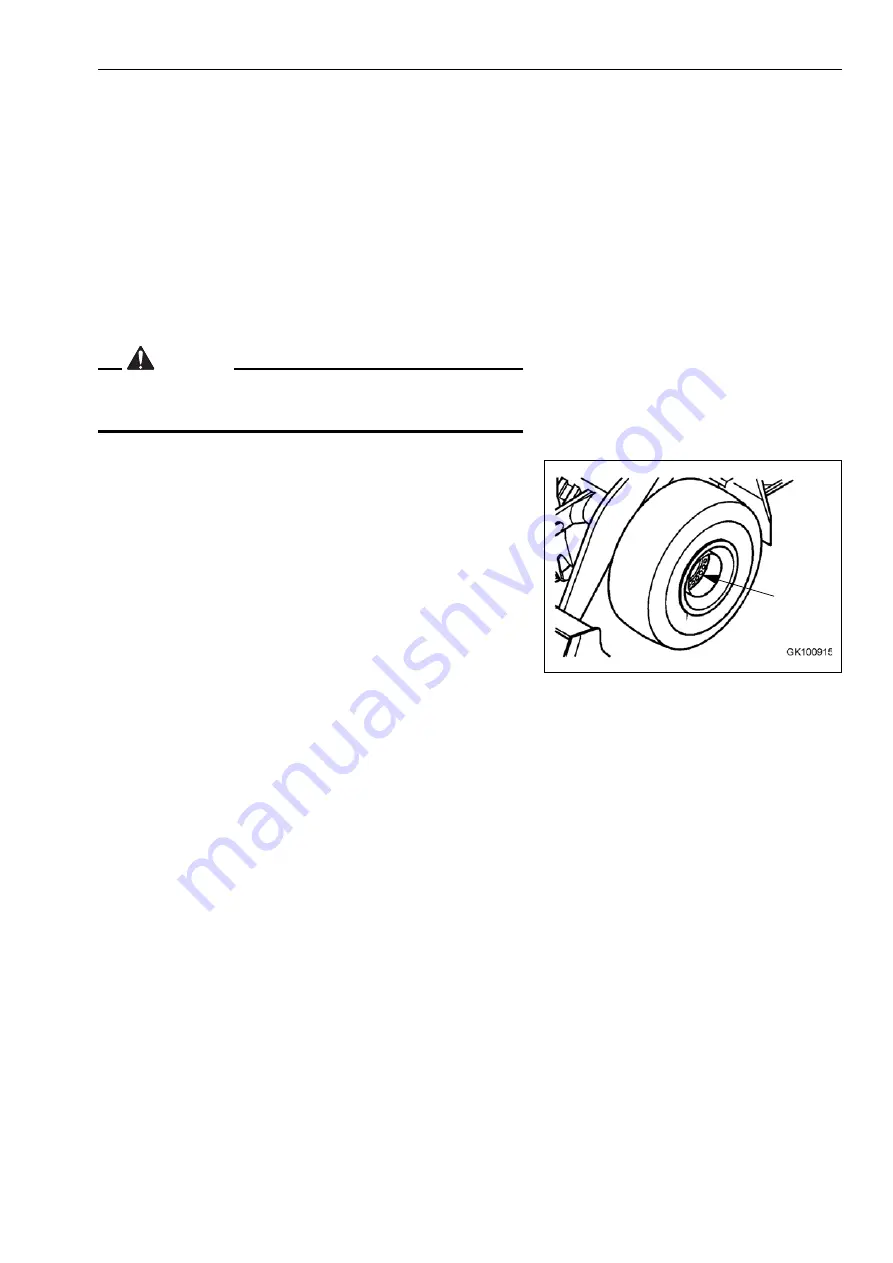

Wheel nuts – check and retighten

WARNING

Loose wheel nuts may cause severe accidents.

Periodically check and retighten the wheel nuts.

Loose wheel nuts (1) increase tyre wear and may cause acci-

dents.

1. Check for loose nuts, and tighten if necessary.

When checking for loose nuts, always turn the nuts in the

direction of tightening.

Torque: 450–500 Nm

2. If any stud bolt is broken, replace all the stud bolts for that

wheel.

1

Summary of Contents for WA70-7

Page 2: ......

Page 3: ...Foreword WA70 7 VENAM02003 1 1 1 Foreword...

Page 23: ...Foreword 1 5 Table of contents WA70 7 VENAM02003 1 21 Blank for technical reason...

Page 28: ...1 7 Equipment Foreword 1 26 WA70 7 VENAM02003...

Page 75: ...Operation WA70 7 VENAM02003 3 1 3 Operation...

Page 114: ...3 2 Descriptions of the individual elements Operation 3 40 WA70 7 VENAM02003 Fuse allocation...

Page 185: ...Troubleshooting WA70 7 VENAM02003 4 1 4 Troubleshooting...

Page 203: ...Maintenance WA70 7 VENAM02003 5 1 5 Maintenance...

Page 277: ...Technical data WA70 7 VENAM02003 6 1 6 Technical data...

Page 283: ...Special equipment attachments WA70 7 VENAM02003 7 1 7 Special equipment attachments...

Page 291: ...Index WA70 7 VENAM02003 8 1 8 Index...

Page 296: ...8 1 Index Index 8 6 WA70 7 VENAM02003...

Page 297: ...Notes WA70 7 VENAM02003 9 1 9 Notes...

Page 298: ...Notes 9 2 WA70 7 VENAM02003...

Page 299: ...Notes WA70 7 VENAM02003 9 3...

Page 300: ...Notes 9 4 WA70 7 VENAM02003...

Page 301: ...Notes WA70 7 VENAM02003 9 5...

Page 302: ...Notes 9 6 WA70 7 VENAM02003...