5.8 Maintenance procedure

Maintenance every 500 service hours

Maintenance

5-50

WA70-7 – VENAM02003

5.8.9

Maintenance every 500 service hours

Also perform all maintenance tasks scheduled to be carried out

every 10, 50, 100, and 250 service hours.

Manual pump – check oil level

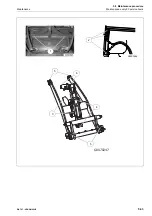

1. The oil level in the hand pump is checked with the cab tipped

down.

2. Remove the screw plug (1).

3. The oil level should be at the lower edge of the filling hole

(arrow).

4. Add oil if required.

For details see 5.4 “Fuel, lubricants, and coolants; quanti-

ties” (5-18).

5. Insert the screw plug into the filling hole and fasten finger-

tight.

G0070267

1

Summary of Contents for WA70-7

Page 2: ......

Page 3: ...Foreword WA70 7 VENAM02003 1 1 1 Foreword...

Page 23: ...Foreword 1 5 Table of contents WA70 7 VENAM02003 1 21 Blank for technical reason...

Page 28: ...1 7 Equipment Foreword 1 26 WA70 7 VENAM02003...

Page 75: ...Operation WA70 7 VENAM02003 3 1 3 Operation...

Page 114: ...3 2 Descriptions of the individual elements Operation 3 40 WA70 7 VENAM02003 Fuse allocation...

Page 185: ...Troubleshooting WA70 7 VENAM02003 4 1 4 Troubleshooting...

Page 203: ...Maintenance WA70 7 VENAM02003 5 1 5 Maintenance...

Page 277: ...Technical data WA70 7 VENAM02003 6 1 6 Technical data...

Page 283: ...Special equipment attachments WA70 7 VENAM02003 7 1 7 Special equipment attachments...

Page 291: ...Index WA70 7 VENAM02003 8 1 8 Index...

Page 296: ...8 1 Index Index 8 6 WA70 7 VENAM02003...

Page 297: ...Notes WA70 7 VENAM02003 9 1 9 Notes...

Page 298: ...Notes 9 2 WA70 7 VENAM02003...

Page 299: ...Notes WA70 7 VENAM02003 9 3...

Page 300: ...Notes 9 4 WA70 7 VENAM02003...

Page 301: ...Notes WA70 7 VENAM02003 9 5...

Page 302: ...Notes 9 6 WA70 7 VENAM02003...