5.8 Maintenance procedure

Maintenance

Maintenance every 2000 service hours

WA70-7 – VENAM02003

5-67

5.8.12

Maintenance every 2000 service hours

Also perform all maintenance tasks scheduled to be carried out

every 10, 50, 100, 250, 500, and 1000 service hours.

Cooling system – change coolant and clean cooling system

WARNING

Danger of scalding! The coolant is pressurised while the

engine is hot. Hot coolant may spurt out when the cooling

system is opened.

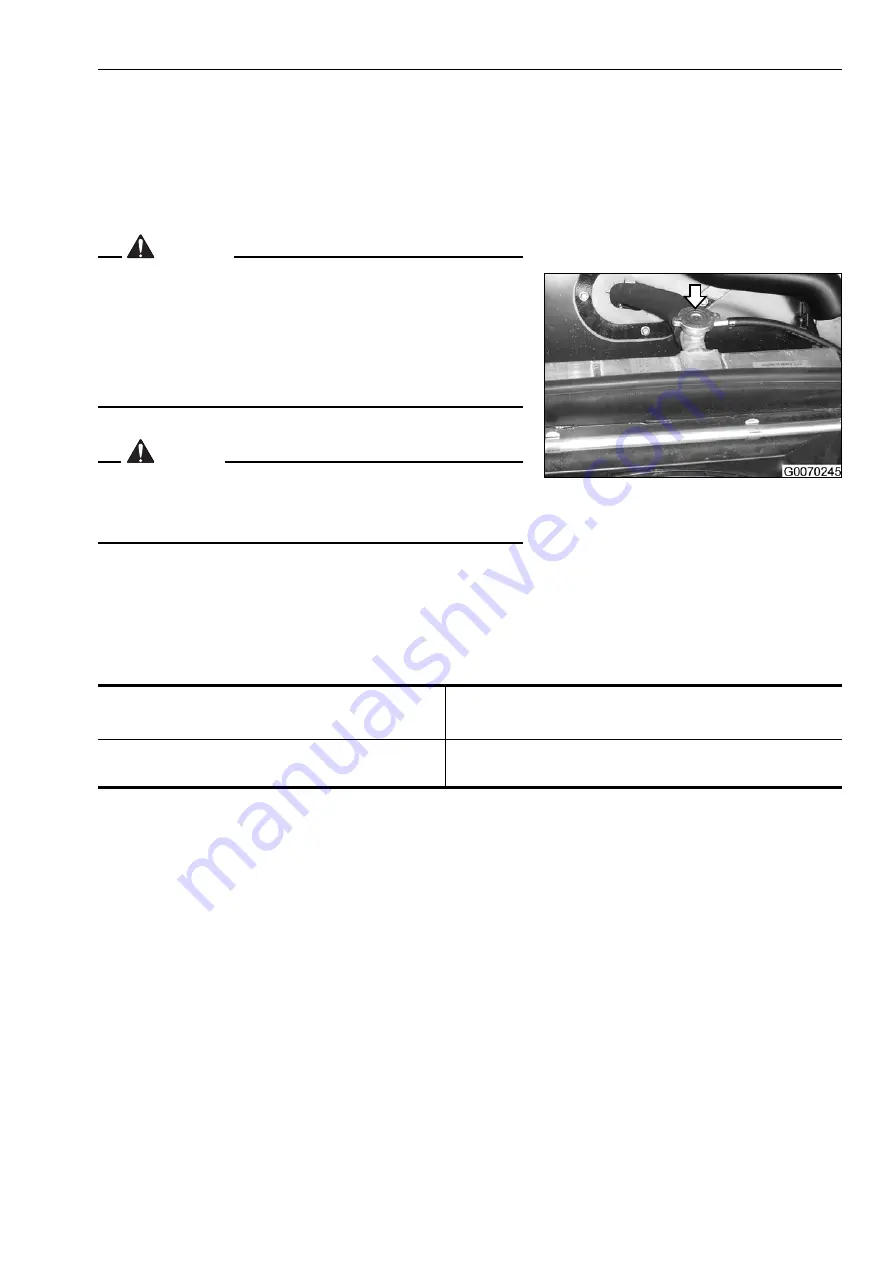

Wait until the engine has cooled down before checking the

coolant level. Slowly unscrew the cap (arrow) to let the pres-

sure escape.

DANGER

Danger of fire! Antifreeze may ignite when making contact with

the hot engine. Wait until the engine has cooled down before

adding antifreeze.

Park the machine on solid, level ground before cleaning the

cooling system or changing the coolant.

Clean the inside of the cooling system, change the coolant and

the anti-corrosive according to the table below.

Operating precautions

When using Komatsu Supercoolant (AF-NAC) there is no need

to use anti-corrosive.

If using anti-corrosive, use Komatsu anti-corrosive exclusively.

Using any other anti-corrosive may cause serious damage, such

as corrosion of the engine or of cooling system components that

use light metals like aluminium.

The coolant has the important function of preventing corrosion

and freezing.

Even in the areas where freezing is not an issue, the use of anti-

freeze coolant is essential.

Coolant/antifreeze

Interval for cleaning the inside of the cooling system

and changing the coolant

Komatsu Supercoolant

(AF-NAC)

Every two years or every 4000 service hours,

whichever is earlier.

Summary of Contents for WA70-7

Page 2: ......

Page 3: ...Foreword WA70 7 VENAM02003 1 1 1 Foreword...

Page 23: ...Foreword 1 5 Table of contents WA70 7 VENAM02003 1 21 Blank for technical reason...

Page 28: ...1 7 Equipment Foreword 1 26 WA70 7 VENAM02003...

Page 75: ...Operation WA70 7 VENAM02003 3 1 3 Operation...

Page 114: ...3 2 Descriptions of the individual elements Operation 3 40 WA70 7 VENAM02003 Fuse allocation...

Page 185: ...Troubleshooting WA70 7 VENAM02003 4 1 4 Troubleshooting...

Page 203: ...Maintenance WA70 7 VENAM02003 5 1 5 Maintenance...

Page 277: ...Technical data WA70 7 VENAM02003 6 1 6 Technical data...

Page 283: ...Special equipment attachments WA70 7 VENAM02003 7 1 7 Special equipment attachments...

Page 291: ...Index WA70 7 VENAM02003 8 1 8 Index...

Page 296: ...8 1 Index Index 8 6 WA70 7 VENAM02003...

Page 297: ...Notes WA70 7 VENAM02003 9 1 9 Notes...

Page 298: ...Notes 9 2 WA70 7 VENAM02003...

Page 299: ...Notes WA70 7 VENAM02003 9 3...

Page 300: ...Notes 9 4 WA70 7 VENAM02003...

Page 301: ...Notes WA70 7 VENAM02003 9 5...

Page 302: ...Notes 9 6 WA70 7 VENAM02003...